Speed Bumps for Sale

JACKWIN is engaged in a wide variety of speed bumps and humps by designing and producing with safety in mind and to efficiently and effectively control speeding cars and vehicles which are generally used in driveways, parking lots, business entrances, and warehouse dock areas.

Speed Bump Meaning

Speed bumps are also called speed humps, speed cushions, tables, speed ramps, or speed breakers. They are usually made from rubber or asphalt. Plastic, metal, and concrete options are available as well. They’re often seen on local streets or connector roads where they need to slow down vehicle’s speed in the heavy traffic.

Best-selling Speed Bumps & Humps

JACKWIN offers all types of speed bumps and humps in different materials(rubber, plastic) and sizes that are used for road traffic safety. If you are a trader, bidder, wholesaler, construction or engineering company, please browse our following most economical and cost-effective speed bumps and you intend to buy(purchase) this speed bumps , we are right here for your best choice.

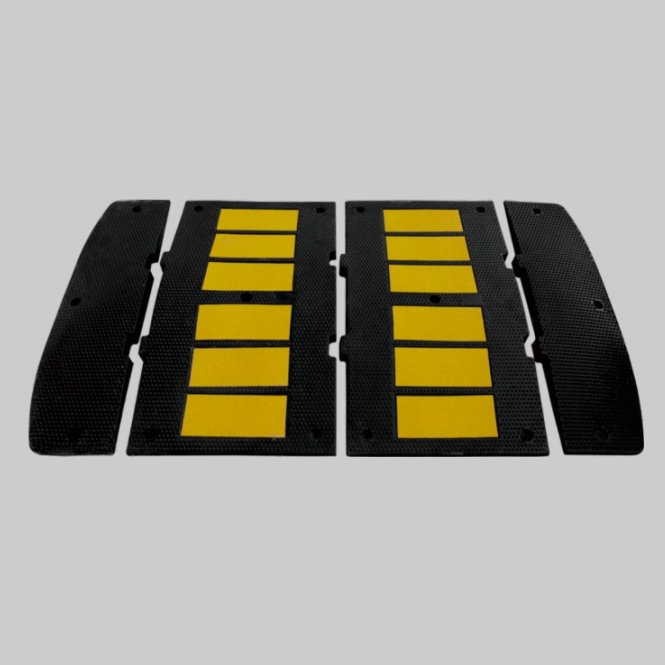

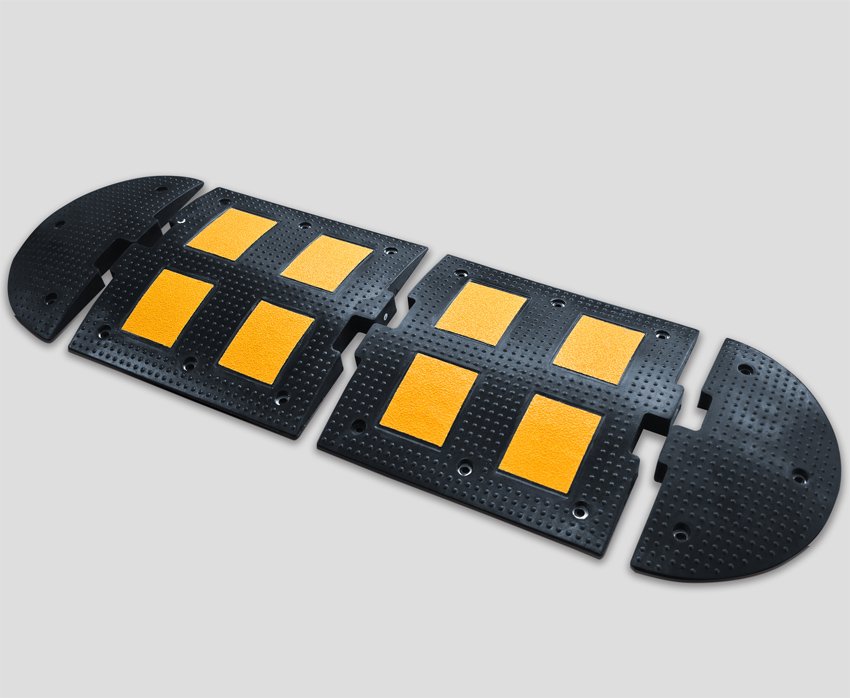

Size 1000x380x50mm, made of recycled rubber material, 15.5kg

20" Rubber Speed Bump

Size 500x350x50mm, 7kg, yellow/black rubber material

Size 900x500x50mm, design for driveway with yellow and white arrow

Size 500x100x20mm, 1kg, mini small speed bump for indoor

Size 250x320x50mm, 1 cable/pipe channel on bottom, glass bead reflector

Max length 3 meters, width 250mm, height 50mm,weight capacity 15tons

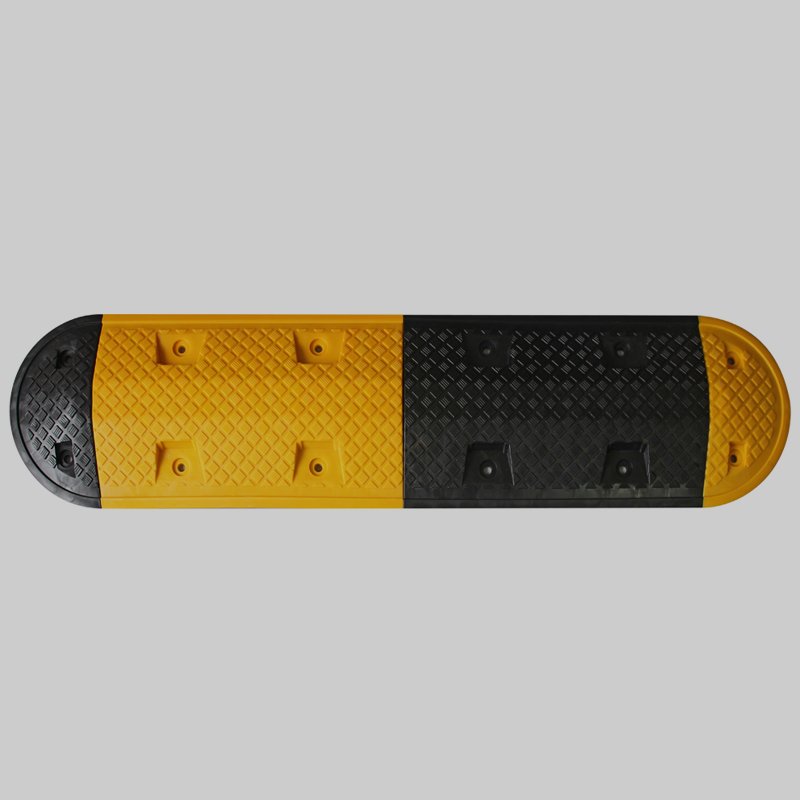

Size 500x320x40mm, made of plastic nylon, 2.5kg/meter

Extensive size 300x25x5cm, 13kg, roll-up and designed for temporary use.

Size 300x170x50mm, 3 kg, with 2 glass bead reflectors on each side, surface mounted by 2 anchor bolts.

High Quality Rubber Speed Bumps

Our rubber speed bumps in this column are of high-end quality and suitable for customers who have higher requirements on quality. The price is a bit higher than the economical ones, but the quality and details will definitely exceed your expectations.

-

JW-JSD-535G Rubber Speed Bump

JW-JSD-535G Rubber Speed BumpHigh quality, white reflective marking, size 500x350x50mm, accept custom debossed logo

-

JW-JSD-540A Rubber Speed Bump

JW-JSD-540A Rubber Speed BumpSize 500x400x50mm, 16kg, anti-slip texture, designed for parking lot

-

JW-JSD-5100A Rubber Speed Bump

JW-JSD-5100A Rubber Speed BumpSize 500(L)x1000(W)x75(D)mm, 25kg, heavy duty speed cushion

-

JW-JSD-550A Rubber Speed Bump

JW-JSD-550A Rubber Speed BumpHeavy-duty, size 500x500x50mm, 17kg, reflective marking

-

-

JW-JSD-555A Rubber Speed Bump

JW-JSD-555A Rubber Speed BumpSize 500x550x75mm, 26kg, anti-slip texture, white/yellow reflective marking

Speed Bumps By Properties

JACKWIN’s speed bumps have many features and advantages. We list some of them below for your reference.

high visible yellow and black reflective stripes to make it visible at night.

one-person easy installation by anchors or bolts.

can resist low and high temperatures outdoors.

not fade, rot, or corrode outside.

made up of 100% recycled rubber material.

made with corrosion-resistant recycled rubber for long-lasting durability.

durable and does not need maintenance.

made of rubber material and waterproof, it can be used outdoors.

grooved surface can make anti-slip.

reflectors can improve nighttime visibility.

protect the bottom wire, cable, pipe, and hose from being damaged.

high weight capacity and not easily be damaged when the cars or vehicles run over.

Your One-stop Speed Bumps and Humps Supplier

JACKWIN offers various sizes and materials of speed bumps and humps for your choice.

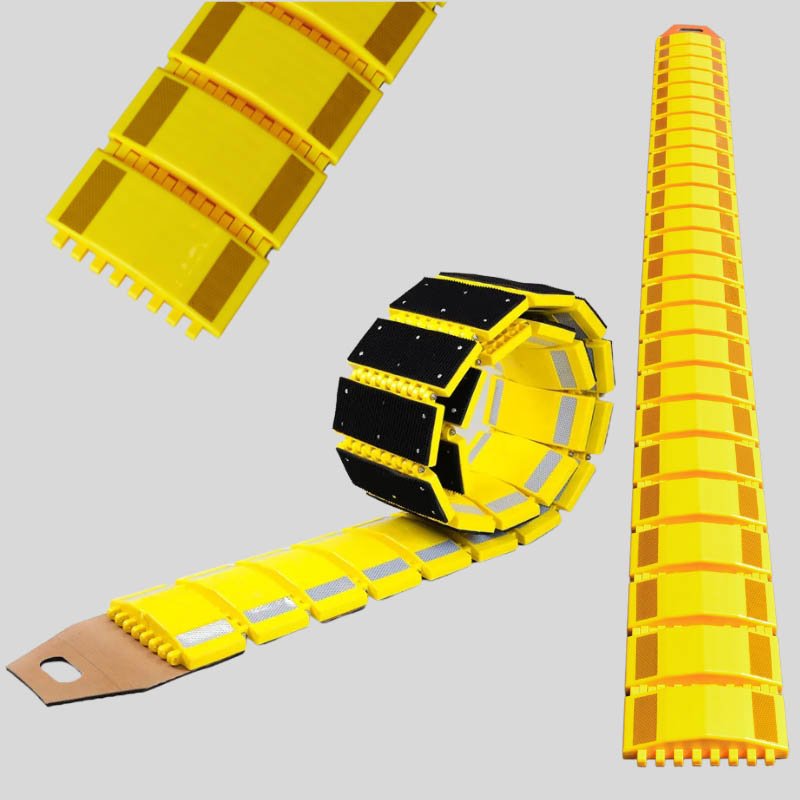

300MM Rumble Bars in Yellow

These rumble bars are special speed bumps made of plastic or rubber. They are manufactured by the JACKWIN factory, which is the most popular and trusted by the Australian market.

Our designed purpose and use are as follows:

1. It is used as curb protection to avoid crashes on the roadside and also to protect buildings and infrastructure.

2. Rumble bars are used as pavement markers/road studs for drivers’ alert in lane dividers, and delineators for traffic management.

3. These rumble bars are used to isolate and restrict designated areas. On certain roads, ramps, or road painting areas, rumble bars are installed to prevent vehicles or pedestrians from driving into the area.

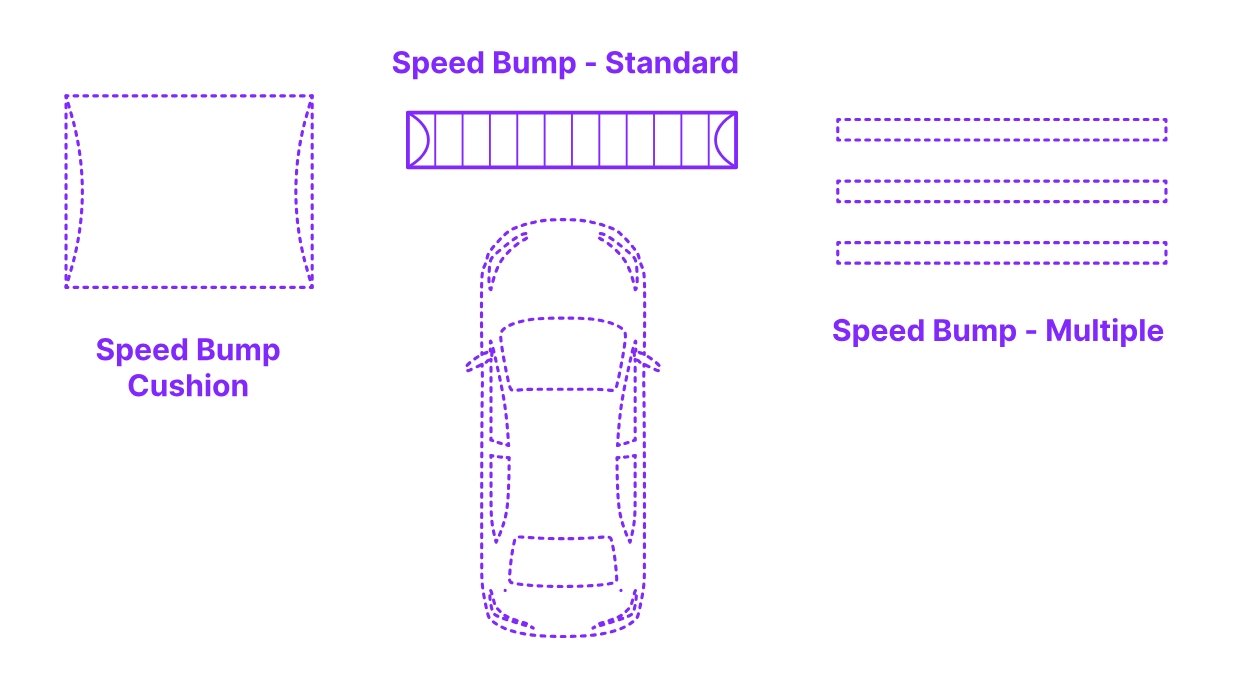

Types of Speed Humps

Speed bumps are classified into several types according to their functions and materials, including concrete, rubber, plastic, and cable speed bumps.

Concrete Speed Bumps, in the 1950s and 1960s, the earliest speed bumps were made of concrete or asphalt. They are the most traditional speed bumps, mainly used in parking lots, school zones, and hospitals.

Rubber Speed Bumps, rubber is a flexible material that is widely used in various types of roads, such as asphalt, dirt, and gravel. Most of the speed bumps on the market are rubber speed bumps, which account for a larger proportion than speed bumps made of other materials.

Plastic Speed Bumps are mainly made of high-density polyethylene (HDPE) as a material and are produced by injection molding. It’s lightweight and portable, and it is mainly used as a temporary speed bump.

Cable Speed Bumps are speed bumps with 1 or 2 channels on the bottom, which can be used to put through cables and protect the cables.

Rubber Speed Bump Advantages

-

- Control vehicle speed – the main function of speed bumps is to control the speed of vehicles, thereby reducing the incidence of traffic accidents.

- Improved visibility– rubber speed bumps can be given a series of reflective stripes that make them even more visible at night or in low-light conditions. This would be particularly useful for sites that operate around the clock to help potentially tired drivers become more aware.

- Reduced Accidents and Damage – in some high-traffic areas, such as schools, hospitals, and commercial centers. Pedestrians are easily hit by vehicles because of their high speed when pedestrians need to cross the road. By setting up speed bumps, vehicles must slow down to improve the safety of pedestrians.

- Easy installation – rubber speed bumps are very easy to install by being fixed directly to the surface with bolts and only one person to operate.

- Environmentally Friendly – it is made up of 100% recycled material, which is sourced primarily from used tires that can protect the environment.

- Cost-Effective – they are made from recycled rubber that is very cheap to buy in bulk compared with plastic or other materials.

Resources

Know more about products and JACKWIN? Just click video link, you can get more than you think.

To learn more about JACKWIN products, please follow our knowledge center.

Plastic Speed Bump VS Rubber Speed Bump

- Material: Plastic speed bump is made up of recycled plastic and rubber speed bump is made up of recycled rubber.

- Weight: Plastic Speed bump is lightweight and rubber speed bump is heavy-duty.

- Reflective: Plastic speed bumps only can use PC reflector lens, but rubber speed bump is usually included in the reflective stripe or glass bead cat eye reflectors and are usually used in nighttime or low light conditions.

- Temperature performance: Plastic speed bump is excellent performance in extreme heat – won’t “curl” or misshapen. On the contrary, rubber speed bumps have perfect performance in extreme cold.

Rubber Speed Bump Applications

JACKWIN speed bumps are used in many locations and occasions. Below we list some for your reference.

used for parking lots to slow down the vehicle’s speed to increase pedestrian safety.

ehicles entering the school area should slow down in advance to prevent students from being hit by high-speed vehicles.

vehicles are about to enter the parking lot and the speed of the vehicle is reduced.

At the entrance and exit of the highway toll station, the vehicle speed is very fast. Speed bumps need to be installed 300 meters before the entrance and exit to force vehicles to slow down in advance.

Used for police checkpoints to force suspicious vehicles to slow down, making it difficult for them to flee and potentially allowing for a safer traffic stop.

Vehicles entering the gas station must pass over a speed bump that reduces their speed to 5 mph.

Rubber Speed Bump Production

The production of rubber speed bumps is divided into many steps. Below I will give you a brief explanation of the most important steps so that you can better understand JACKWIN’s speed bumps.

The vulcanization molding of rubber speed bumps is a process in which vulcanization temperature and time are controlled, and they are the two most important factors that determine the quality of the speed bumps.

Trimming and burring is a very small step that requires workers to have great patience and rich experience. The knife needs to be very sharp, and the time to choose trimming is also very important. It is better to cut when the speed bump is hot and cut cleanly.

For rubber mixing, we need to mix and crush the raw rubber and other ingredients, press them into sheets on the internal mixer, and then cut them into pieces and weigh them for use.

For the packaging of rubber speed bumps, if you do not have special requirements, we use woven bags for packaging. If you need cartons and pallets, I can customize cartons and pallets for you.

More About JACKWIN Rubber Speed Bump

Below are the parameters of some of our best-selling speed bumps for your reference and understanding. If you have more needs, please contact us now and we will reply to you as soon as possible.

- Specifications

| Item Number | Material | Middle Section Size | Middle Section Weight | End Cap Size | End Cap Weight | Color |

| JW-JSD-001 | Rubber | 1000*350*50mm | 15.5kg | 190*350*50mm | 2kg | B/Y |

| JW-JSD-002 | Rubber | 500*300*50mm | 6kg | 250*300*50mm | 2kg | B/Y |

| JW-JSD-003 | Rubber | 500*350*50mm | 7kg | 175*350*50mm | 1.8kg | B/Y |

| JW-JSD-004 | Rubber | 1000*350*50mm | 14kg | 175*350*50mm | 1.8kg | B/Y |

| JW-JSD-005 | Rubber | 250*350*50mm | 3.75kg | 175*350*50mm | 1.8kg | B/Y |

| JW-JSD-006 | Rubber | 600*500*32mm | 9kg | 600*250*32mm | 3kg | B/Y |

| JW-JSD-007 | Rubber | 900*500*50mm | 19kg | 900*250*50mm | 7.5kg | B/Y |

| JW-JSD-008 | Rubber | 500*500*75mm | 17kg | 250*500*75mm | 5kg | B/Y |

| JW-JSD-009 | Rubber | 500*350*50mm | 7kg | 175*350*50mm | 5kg | B/Y |

| JW-JSD-010 | Rubber | 500*480*50mm | 9.5kg | 170*400*50mm | 2.8kg | B/Y |

| JW-JSD-011 | Rubber | 1000*300*50mm | 13kg | 150*300*50mm | 1.3kg | B/Y |

| JW-JSD-012 | Rubber | 500*430*50mm | 11kg | 250*430*50mm | 4kg | B/Y |

| JW-JSD-013 | Rubber | 500*350*50mm | 9kg | 250*350*50mm | 2kg | B/Y |

| JW-JSD-014 | Rubber | 500*500*55mm | 14kg | 270*500*55mm | 4kg | B/Y |

| JW-JSD-015 | Rubber | 1830*300*58mm | 21kg | 150*300*58mm | 2.2kg | B/Y |

| JW-JSD-016 | Plastic | 3000*250*50mm | 13kg | / | Y |

Customers' Feedbacks

We use standard export pallets for speed bumps and protective film, corner guards and package belts for fixtures.

We have two materials for you to choose from, plastic speed bump and rubber speed bump. According to your installation location, length and budget, we will recommend the right product for you to choose. The final choice is in your hands.

Related Product

Speed Bump Standards

Speed bump is a raised slope made of rubber, metal, or plastic that hinders vehicles on the road and reduces their speed. Therefore, its standard must be regulated in terms of length, height, spacing, slope, material, installation, location, and regulation.

Speed Bump Length

The length of the speed bump single piece is 500mm, 1000mm, and 1830mm. Usually, the single pieces are connected to achieve the required length according to the width of the road. In addition, end caps are installed at both of the outermost ends. The end cap is semicircular and has a certain slope to play the role of finishing the edge.

Speed Bumps Spacing

The maximum spacing between speed bumps installed on a highway should not exceed 500 feet while achieving the 85th percentile of speeds between 25 and 35 mph.

Speed Bump Height

The height of the speed bump is usually around 2″, and it should not be too high or too low. If it is too high, the vehicle speed will be too fast and the vehicle will fly up, causing a traffic accident or caused car damage from speed bumps. Of course, the deceleration effect is not good enough if the height is too low. According to practice and research, 2″ is the most suitable height.

Speed Bump Slope

For safety and effect considerations, slopes must be between 1:10 and 1:25.

Speed Bump Material

There are several materials to choose from for speed bumps. The speed bumps on the market are mainly made of rubber. Rubber is similar to tires in composition, has a certain elasticity, and is also very wear-resistant, so it is the most suitable material for producing speed bumps. In addition, there are speed bumps made of metal and plastic, but metal and plastic are relatively hard and not friendly to tires, so they are not widely used in the market.

Speed Bump Installation

Speed bumps are usually installed on concrete or asphalt pavement. The installation steps are as follows:

First, after laying the speed bump on the road, locate and mark the screw holes

Second, use a punch to drill holes in the marked screw holes.

Finally, tighten the expansion screws to fix the speed bump, and the installation is complete.

Speed Bump Location

Speed bumps are usually installed on roads in urban streets to increase pedestrian safety, such as in front of traffic lights, schools, and hospitals, but they are generally not suitable for highways.

Speed Bump Regulations

Speed bump regulations vary from country to country and even from location to location. For example, Florida speed bump regulations are different from other states. Therefore, the same speed bump may not be suitable for all national standards, but JACKWIN has a wide variety of speed bumps that meet the standards and regulations of each country. Therefore, you can always choose a speed bump that suits you here.

How to Get Speed Bumps Installed on Your Street?

If you want to get speed bumps installed on your street, you need to contact your local government or local road administration department in advance, follow their procedures and apply to them. Usually, you need to provide some evidence to prove that the road on your street needs to install speed bumps. The procedures of each local government may be different.

After a series of verifications and studies by the local government department, they will get approval. They will send engineers to the road site to survey the installation location and length. After obtaining these data, they will announce the bidding information to the public. The winning supplier will provide speed bumps according to the requirements and install them within the specified time.

Speed Bumps VS Speed Humps

Speed bumps and speed humps have the same concept, but the difference between them is that the height of speed bump is shorter than that of speed hump, but the length is longer. So their application locations are also different. Speed bumps are more suitable for parking lots.

- Design, speed bumps are shorter than speed humps, but speed humps are more fatter.

- Material, both of them are made of same material(rubber, iron or plastic).

- Use and Purpose, they are used for reducing vehicles’ speed and purpose is to improve the safety of people.

- Effect, speed humps are more soft and easy to absorbs wheel shocks, reduces speed better, and makes the driver and passengers more comfortable.

Speed Table VS Speed Bump

Both of them are speed bumps as traffic tools in road management. The difference is that the length of speed table is longer than speed bump and the top is flat to convenience the vehicle to reduce its traffic speed. However, the length of speed hump is shorter than speed table and with ramp-topped.

-80x69.png)