Several facilities make the mistake of using the wrong safety flag in different environmental conditions. Like using a red flag in a low-light setting where visibility is already compromised.

That’s why it’s very important for every facility to understand safety flags, their types, color coding, and which safety flag to use in which environmental conditions. And that’s exactly what we’ve explained in this guide for you. So that you know the distinction between safety flags, improve on-site safety, and comply with industry standards.

Definition of a Safety Flag

A safety flag is a simple yet powerful safety warning tool. It’s generally made from sturdy materials and comes in bright colors to improve visibility. Its main purpose is to communicate with people and warn them about potential dangers or signal-specific conditions.

Facilities use these flags across various environments, such as construction sites, roads, warehouses, airports, marine zones, sports events, and several other sites, to warn or inform people at/ around the site about danger. They are available in different shapes, sizes, and colors, each designed to serve a unique purpose.

Meaning of a Safety Flag

Safety flag meaning, or let’s say its purpose, is simple. And that’s to alert and warn people about a potential hazard ahead or nearby. So whenever you spot a safety flag, know that it’s telling or warning you for potential danger so you move cautiously.

For instance, suppose you’re working on a construction site, and you spot a yellow flag mounted somewhere around your worksite. That flag is simply warning you that the area ahead might be dangerous. So you should approach with caution. If you ignore the flag, you put yourself in danger and unsafe situations.

Why Safety Flags Matter in Professional Settings?

Safety flags play a huge role in several professional settings. Whether it’s a construction site, a manufacturing facility, a sports event, or a transport operation. Below, we have explained how they matter so much:

- They keep your workers safe:

Safety flags are placed to alert workers and visitors about what’s going on in a specific area. For example, a red flag is mounted at a certain zone, indicating a restricted or dangerous zone. So they won’t cross the zone. Without that flag, workers might step into danger unknowingly, which can lead to injuries or even fatal accidents.

- They guide drivers and equipment operators:

Suppose you’re managing a construction where multiple vehicles are moving around. If there are no visual signals like safety flags, your drivers or equipment operators may enter the wrong zone. But when you properly place flags in place (like orange or green safety flags), you can guide vehicle movement and avoid collisions.

- They create a more professional and organized worksite:

When you use safety flags properly at your worksite, it shows that you take your operations seriously and care about your workers and other safety at your worksite.

- They ensure legal compliance and reduce liability:

In industries like transportation, construction, and energy, you are required to use safety signals (like flags) to comply with the law. So, when you follow these rules, you protect your business from legal trouble and avoid penalties. Plus, it potentially reduces the risk of being held responsible for workplace accidents.

- They support quick communication during emergencies:

Suppose an emergency happened at your facility. Like a sudden equipment failure or chemical spill. In such conditions, not everyone can hear alarms or announcements. Here, you can place an appropriate safety flag around the hazard site and immediately alert your workers. So they won’t enter the hazard zone.

- They’re simple but powerful safety tools:

A basic safety flag, when used in the right place at the right time, can do the safety-job. It’s a cost-effective solution, easy to move, and instantly effective in getting attention (where it’s needed).

Different Types of Safety Flags

By Material Type

Safety flags are typically made with durable material to cater to different environments and visibility conditions. The most common materials leading safety flag manufacturers use are:

- Polyester

Benefits: Highly durable, good color retention, water-resistant, can be easily stretched, ideal for outdoor and industrial use

Drawbacks: More expensive than nylon, can fade over time under UV exposure, heavier than nylon flags (so it affects movement in windy weather)

- Vinyl Safety Flags (PVC):

Benefits: Extremely durable, waterproof, weather-resistant, flexible, easy to fold, and ideal for use in marine and heavy-duty industrial areas.

Drawbacks: Heavy and stiff, limited movement in light winds, more expensive, and prone to cracking in extreme cold

- Nylon Safety Flags

Benefits: Lightweight, brightly-colored, easy to handle, affordable, quick-drying, good for moderate weather, holds color well (so ideal for longer-term use or events)

Drawbacks: Can tear under strong wind, not suitable for very rough outdoor conditions, absorbs moisture, fades under UV exposure

- Mesh Safety Flags (Polyester or Nylon)

Benefits: Air passes through (perfect for windy areas), prevents tearing in high-wind zones, lightweight, easy to install and ideal for high-wind areas, construction sites, sports fields.

Drawbacks: Less visible from long distances, can fade quicker under direct sunlight

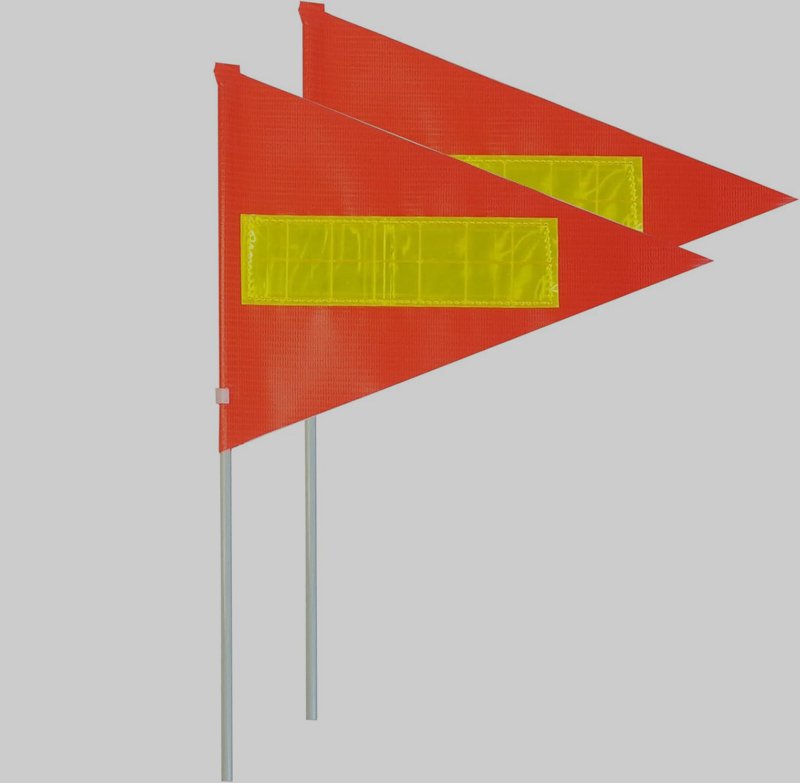

- Reflective Materials (Polyester or Vinyl with Reflective Coating)

Benefits: Enhance visibility in low-light conditions or nighttime/ fog, can be easily added with other materials for increased durability, ideal for use during road work, nighttime safety, and emergency signaling.

Drawbacks: Over time, the reflective coating wears off, and it is more expensive compared to other materials.

- Cotton or Canvas

Benefits: Natural, biodegradable material, soft, traditional look, and ideal for decorative and temporary use

Drawbacks: Not water-resistant, less durable, easily dirtied, and fades under sunlight.

By Color Coding (With Meaning)

In the market, you’ll see safety flags in various colors. Therefore, it’s important for you to learn about the color coding of flags as each flag color caters to different meanings and use cases as per local and international compliances:

| Color | Meaning | Common Use Cases |

| Red | Danger / Stop | Hazard zones, emergency areas, and machine stop signals |

| Orange | Warning / Construction | Ahead Roadworks, utility work zones, and excavation sites |

| Yellow | Caution / Slow Down | Maintenance zones, gas lines, pedestrian walkways, and inspection areas |

| Green | Safety / Go / First Aid | Safe paths, emergency exits, assembly points, and drain lines |

| Blue | General Information / Instructions | Direction signs, visitor guidance, equipment instructions, and water pipe |

| White | Non-hazard / Route Guidance | Traffic flow signs, designated entry/exit points |

By Size

Safety flags come in different sizes according to standard visibility needs:

- 6 x 9 cm

- 12 x 12 cm

- 18 x 18 cm

- 24 x 24 cm

- 30 x 30 cm

- 45 x 30 cm

- 45 x 45 cm

- 45 x 60 cm

- 50 x 50 cm

Note: The size of customized safety flags may vary based on design requirements!

By Mounting Type

Apart from variations in color, safety flag also varies in mounting type. Let’s discuss all mounting types for safety flags:

- Handheld Safety Flags

- These are mounted on poles or sticks and held manually.

- Mostly flaggers, traffic guides, or warehouse staff use them (during live movement).

- Ideal for use in temporary, short-term, or mobile use.

- Magnetic Mount Safety Flags

- Features a magnet base that sticks firmly on metal surfaces.

- Commonly used on vehicles, forklifts, and trailers.

- Easy to install and remove.

- Clamp or Bracket-Mounted Flags

- Come with brackets or clamps to attach to poles, fences, or barriers.

- Great for permanent or semi-permanent setups.

- Used in construction zones or factory entrances.

- Vehicle-Mounted Safety Flags

- Commonly used on heavy-duty vehicles. Like tractors, loaders, or mining trucks.

- Increase vehicle visibility in busy or dangerous areas.

- Often used along high-visibility or reflective features.

By Reflectivity or Visibility Feature

Sometimes, standard-colored safety flags don’t properly warn people due to low-light conditions. Therefore, for such conditions, reflective safety flags are designed using reflective materials or accessories for added visibility. Let’s discuss their types:

- Reflective Safety Flags

- Have reflective strips or coating.

- Useful in night shifts, foggy areas, or dimly lit worksites.

- Often used on vehicles and roadside works.

- LED Safety Flags

- Built with LED lights for ultra-high visibility.

- Best for mine, nighttime operations, or emergency zones.

- Either flash or remain steady (based on the setting).

- High-Visibility (Hi-Vis) Fluorescent Flags

- Made from neon-colored material (like lime, orange, or pink).

- Instantly catch attention, both in daylight and low-light conditions.

- Commonly used on roadwork, traffic control, and warehouse zones.

Safety Flag Accessories and Add-ons

Although, safety flags alone do a great job and properly alert and guide people. But if you pair them with the right accessories, they become even more functional, durable, and easy to use. Especially in busy industrial settings, construction zones, warehouse operations or windy areas.

For example, if your team works at night, you can add reflective strips or LED’s to your flags. This helps enhance visibility of your flags and people will spot them easily (especially in low-light condition). And hence, take precautions while moving ahead. Or, if you use flags on vehicles, you can use flag poles with magnetic bases/ clamps to fix the flag.

Here’s a list of common safety flag accessories you can add:

- Mounting brackets and clips

- Flexible fiberglass flag poles

- Heavy-duty magnetic bases

- Vehicle clamps for trucks, forklifts, or carts

- Reflective strips

- Weighted bases for ground use

- LED lights for nighttime visibility

- Weather-resistant flag covers

- Custom label tags (Zone A, Visitor Area, etc.)

- Ropes for flag adjustments

These small upgrades not only enhance the visibility of the flags but also boost your team’s overall safety and communication.

Regulations and Standards for Safety Flags

When choosing and using safety flags in public places, it is crucial to adhere to the standards and regulations set by your local and international safety organizations. Below, we’ve summarized regulations from each compliance body in a table:

| Standard/ Regulation | Scope & Requirements | Flag Specifications | Compliance Requirements |

| OSHA 29 CFR 1926.200 | Requires safety flags for hazard marking, equipment visibility, and traffic control in construction. | – Red/Orange for hazards

– Minimum size: 18″ x 18″ (varies by use) |

Flags must be visible to all workers; they must be replaced if faded/damaged. |

| ANSI/ISEA 107-2020 | High-visibility safety apparel/accessories (including flags) for road workers. | – Fluorescent red-orange or yellow-green

– Retroreflective strips (optional) |

Flags must meet ANSI color and reflectivity standards. |

| MUTCD | Governs flagger operations in roadwork zones (e.g., hand-signaling flags). | – Red = Stop

– Orange = Warning – White = Guidance |

Flagger flags must be 24″ x 24″ minimum; certified training required. |

| FMVSS No. 108 (DOT) | Safety flags for oversized/wide-load vehicles (e.g., trucks, trailers). | – Red/orange, minimum 12″ x 12″

– Reflective at night |

Flags must be mounted on all protruding loads (DOT inspections apply). |

| ISO 3864-1:2011 | International safety colors/symbols for hazard communication. | – Red = Prohibition/Danger

– Yellow = Caution – Blue = Mandatory action |

Flags must use ISO-defined Pantone colors for consistency. |

| MSHA 30 CFR Part 56/57 | Visibility flags for mining equipment and hazardous areas. | – Red for emergencies

– Fluorescent for low-light conditions |

Flags must be inspected daily; non-compliant flags must be removed. |

| NFPA 704 (Fire Diamond) . | Flags/labels for chemical hazards (flammability, health risks) | – Red = Flammable

– Blue = Health Hazard – Yellow = Reactivity |

Flags must be posted at storage sites; color codes enforced. |

| EN 12899 (EU Standard) | European standard for permanent traffic warning devices (e.g., flags on poles). | – Red/White or Yellow/Black stripes

– UV-resistant material |

Must withstand weather conditions for 5+ years. |

| CSA Z96 (Canada) | High-visibility safety standards for flags in work zones. | – Fluorescent orange or red

– Retroreflective edges |

Complies with Canadian OH&S laws for visibility. |

Common Applications of Safety Flags Across Industries

-

Highway and Road Construction

On highways and road construction zones, facilities use safety flags to warn workers and others about any hazardous areas. Because usually there’s a lot of noise in such sites and any announcement won’t work. These flags instantly grab people’s attention, guide vehicles, alert drivers about ongoing work or hazardous area, and reduce accident risks.

-

Cycling and Slow-Moving Vehicles

Bicycles, golf carts, or tractors during an event are often hard to spot on the road. That’s why facilities attach vehicle safety flags to the back of these vehicles. This helps improve their visibility, especially on rural roads or during cloudy weather. Plus, warn other vehicles from a distance to prevent collision chances.

-

Beaches and Coastal Areas

At beaches, different colored safety flags are used to signal water and other conditions. For example, using a red flag means “danger – no swimming,” while yellow could warn of moderate surf. That way, facilities effectively guide visitors, reduce water accidents, and help maintain order (especially during holidays or crowded days), all by using safety flags.

-

Sports and Racing Events

In events like auto racing, bike races, or marathons, safety flags send signals to participants. For instance, a yellow flag tells racers to slow down (due to a hazard ahead). That way, organizers easily maintain control and alert participants in real-time, to ensure everyone stays safe on the track.

-

Construction Sites

Since high-risk work and construction zones involve heavy machinery and moving parts. Here, safety flags help facilities separate safe areas and danger zones by placing safety flags near areas. This helps authorities mark restricted sections, direct vehicles, or highlight crane zones.

-

Warehouse and Industrial Facilities

In warehouses, standard or reflective safety flags aid in improving visibility, especially around equipment. Staff generally attach flags to moving vehicles or hang them. This helps others warn about high-risk corners and keep everyone safe.

-

Utility and Surveying Work

In electrical line work or land surveying, safety flags let utility teams mark underground cables, boundaries, or danger zones. That way, these flags act as visual reminders for workers and the public to stay cautious. Plus, they help avoid digging-related damages and make inspection work more efficient and secure.

-

Marine and Boating

On boats or near docks, safety flags signal various conditions. Such as a diver in the water, emergency situations, or towing in progress. This way, they help avoid big hazards like preventing boat-to-boat collisions or other accidents. Apart from that, they’re also required by law in some waters for marine safety.

-

Agricultural Fields and Equipment

On tractors, harvesters, or irrigation lines, farmers use safety flags. Because in such sites, equipment often moves slowly and operates in open fields. So these flags boost visibility and help keep both workers and passing drivers alert and safe.

-

Public Events and Crowd Control

Event organizers widely use safety flags to manage crowds and guide foot traffic. Whether it’s a music festival, parade, or public rally, these flags help direct people, signal emergency routes, and create visual boundaries. They also reduce confusion, improve flow, and make crowd handling easier for event staff and security teams.

What is the Safety Flag Price?

To be exact, the price of safety flags varies depending on the size, color, material, key features, brand, and supplier you choose. Plus, if you go for custom-made safety flags with your brand name, logo and other requirements then the price slightly increases and changes.

But if we talk about the general price range, it starts from as low as $3 and can go up to $25+/ flag. A standard polyester flag (without poles) costs you between $3 to $8 each. While heavy-duty vinyl flags cost you between $10 to $20. On the other hand, if you go for safety flags with poles or mounts, they can cost around $15 to $25.

However, if you buy in bulk, then the price of flags goes down per unit. But if you purchase from a wholesale safety flags supplier like Jackwin, the price may further go down. Jackwin’s safety flags price range starts from $0.9 per piece and increases based on the material type, size, custom-made and use-case specific flags.

Custom Safety Flags: When and Why to Use Them?

Well, if we talk about this, then we simply say that you should use custom safety flags when standard safety flags aren’t enough for you and don’t provide clear guidance. They can come to help you in several ways and communicate safety information clearly and effectively.

Here’s when and why you should consider using them:

- When You Need Clear Instructions

Let’s say your warehouse has different zones dedicated to heavy lifting, high-voltage areas, and moving equipment. In such zones, you can mount custom flags with personalized messages. Such as “Crane Overhead – Keep Distance” or “Forklift Zone – Authorized Staff Only.” They give your workers and others clear and direct instructions (that generic flags can’t).

- When You Want to Match Company Branding

Some businesses prefer keeping their branding consistent, even with safety devices and tools. So, if you want to increase brand awareness while working, you can get custom-made safety flags with your logo, company colors, or department names on them. It’s a simple touch, but it shows professionalism and builds trust among clients, staff, or visitors.

- When Language or Symbols Matter

If your team includes multilingual workers, it’s a good practice to use a custom safety flag. Here, you can use flags designed with bilingual messages or pictograms. For example, a flag with “DANGER – PELIGRO” message ensures everyone understands the warning. Plus, it also reduces confusion and improves safety.

- When Organizing Events or Temporary Work Zones

During site inspections, client visits, or temporary repairs, you can use custom flags with labels like “Visitors Area” or “Inspection In Progress.” These flags help you effectively manage temporary setups.

- When You Need to Stand Out in Busy Sites

In large outdoor or industrial sites, basic red or orange flags can blend in (especially in low-light conditions). But with custom colors or reflective designs/ strips, your custom safety flags will be highly-visible and provide a clear warning signal.

Conclusion:

To wrap up, you can see that safety flags are an essential and cost-effective safety tool for facilities to manage, guide, and warn people about boundaries and danger areas. However, you just need to use a correct safety flag (based on your use case) or get customized safety flags.

So, if you’re looking for high-quality yet affordable safety flags, check Jackwin’s safety flag catalog. We have a wide variety of safety flags across various colors, sizes, and industry-specific categories. We also accept customized safety flag orders with your shared requirements. So, contact our team today to get an instant inquiry!

-80x69.png)