Manufacturing companies use several raw materials to produce rubber. As a rubber manufacturer, it’s important for you to understand all the raw materials that are used in rubber-made items because these raw materials will actually decide how your product will perform.

Therefore, this guide will show you how many types of rubber raw materials are there that you can use. You will also know which raw materials of rubber are good for your outdoor & indoor projects.

Types of Rubber

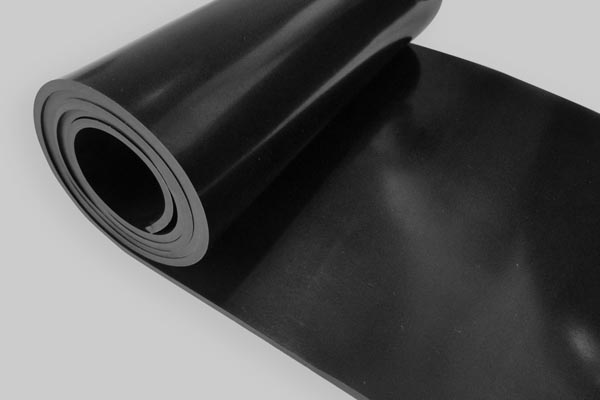

Rubber is a strong and flexible material & has unique properties. You can easily bend it and convert into your desired shape. That’s why many industries use rubber for the manufacturing of their different products. However, there are two types of rubber that are generally used.

Natural Rubber (NR)

Natural rubber is soft, high-strength, and you can classify it as a polymer. It is extracted from a white liquid called latex. You can take this liquid (latex) out of rubber trees if you make small cuts.

When you extend natural rubber, it can go back to its shape. With the help of natural rubber, you can construct multiple items. For example: car and airplane tires, gloves, medical tools, baby toys, clothes, and many more.

Synthetic Rubber

Synthetic rubber is a type of rubber that you can make from chemicals. These chemicals are acquired from different types of oils in factories. Furthermore, you can produce synthetic rubber through polymerization.

List of Raw Materials in Natural Rubber

As we mentioned, the main raw material for natural rubber is latex. You can find top-quality latex from the tree called Hevea brasiliensis. For example, when you cut the bark of this tree, you will see how it comes out.

After latex liquid is discharged from the bark of tree, it also contains a chemical which is polyisoprene. This chemical has a quantity of water, fats, sugars and small amounts of other things too.

Common Additives Used

During the process of natural rubber production, you have to add some other ingredients. These all are known as additives. Following are major additives you need.

- Fillers

- Antioxidants

- Sulfur (vulcanization)

- Accelerators

- Colorants (for color)

Raw Materials Used in Synthetic Rubber

Instead of tree sap, companies make synthetic rubber from elements found in crude oil. We have listed them below.

-

Styrene-Butadiene Rubber (SBR)

Styrene Butadiene rubber is the mixture of two special materials, styrene and butadiene. SBR is one of the most common rubbers in the world. You can use SBR when you need durable, strong and cheap rubber for your projects. As per your requirements, you can also mix these materials with other ingredients for better production.

-

Nitrile Butadiene Rubber (NBR)

Nitrile Butadiene is used in the production of rubber by manufacturers due to its excellent ability to handle fuel, hot/cold, and grease damage. Mostly, the automotive and aerospace industries use NBR raw materials. The only reason is its strong resistance to gasoline, acids, and chemical compositions. You can also use it in places as cold as -40°C and as hot as 108°C.

-

Butadiene Rubber (BR)

Well, Butadiene Rubber gives you outstanding results when you combine it with other materials. Hence you should mix it with styrene-butadiene, acrylic-butadiene, natural and chloroprene. If your business is related to tires & automotive manufacturing, we will recommend you to choose BR material.

-

Ethylene Propylene Diene Monomer (EPDM)

Rubber equipment that is needed to install outdoor locations, made from Ethylene propylene monomer. Because it gives your tools high protection from rain, sunlight, and temperature, another property that you will find in it is that this raw material never cracks and is long-lasting. That’s why you often see it in car seals, roofing, and garden hoses.

-

Isobutylene Isoprene Rubber (Butyl)

Butyl is an airtight type of material because it can hold the air and gasses effectively. This raw element is achieved when you combine different materials in a special way. We will suggest you don’t choose Butyl when you need oil & heat resistance. However, it will be your ideal option for tires, seals and waterproof items productions.

-

Neoprene (CR)

Neoprene is a type of synthetic rubber. You can use it when you need something strong and flexible. Plus, it always works very well in heat, cold, and water. You can make wetsuits, gloves, belts, and seals from this rubber. They will last a long time, so it’s a good choice for you if you want high-quality items. Neoprene is also a good choice when you want rubber that can handle your tough jobs.

-

Acrylic Rubber

If you want excessive heat and oil resistance material, Acrylic rubber is the ideal material for you. Due to this property industrial sectors widely use this raw material. Equipment which is made from acrylic rubber mostly installed in your cars engines.

-

Hydrogenated Nitrile Butadiene Rubber (HNBR)

HNBR is the advanced version of NBR (Nitrile Butadiene Rubber). It is a beneficial material for your machines that operate under heavy loads and in tough conditions. Also, you can choose it when your industry is related to automotive, gas drilling, and defense. Plus, you can also get benefits from this substance if your factory produces industrial tools.

-

Chlorosulfonated Polyethylene (CSM)

CSM is generated by a complex process in which different types of materials are put together. As a result, you will get materials which have great properties to manage ozone, UV radiation and chemicals. Moreover, You can find this rubber in things like pipe covers, seals and rubber tubes.

-

Methyl Vinyl Silicone Rubber (MVQ)

Methyl Vinyl Silicone Rubber is a special kind of rubber raw material. It is flexible and resistant to water, oils and dangerous chemicals. In addition, you can use it when other rubbers melt and crack. The reason is that it does not get hard in the cold and doesn’t break down in the heat also.

Natural vs Synthetic Raw Materials of Rubber

If you run a rubber industry or you are a safety equipment manufacturer, you should know about the major difference between synthetic and natural raw material of rubber.

Below is a simple table that shows you what makes these two materials different.

| Aspects | Synthetic Material | Natural Material |

| Elasticity | Changes depend on type- some are more rigid | Extremely flexible & bendable |

| Temperature Resistance | -70 – 180 °C | -40 to 80 °C |

| Sunlight Protection | Weak to strong capability | Poor resistant |

| Outdoor Applications | Some types may be suitable, others will not | Good durability in open environments |

| Damage from Rubbing | Have average ability against rubbing | Hard to scratch |

| Pull Strength (%) | 800 | 150 – 800 |

| Biodegradability | Non-biodegradable | Fully biodegradable |

| Cost | Generally, it is less expensive to produce | More expensive due to the natural source |

JACKWIN Safety Products Made From Rubber

When you need durable and flexible safety equipment, rubber-made products are always an ideal option. JACKWIN is the top supplier of road safety rubber tools in China. Below, we list our range of rubber-made products that you can purchase at affordable prices.

Rubber Speed Bumps

Rubber speed bumps have different applications due to its excellent safety feature. You can install them at traffic stops & toll gates. These bumps can also be used to slow down vehicles in your parking lots, school zones, warehouses and gas stations.

Plus, it has a long lifespan, quick setup and you can recycle it also. These speed bumps have reflective strips, so that you can spot them from far distances.

Traffic Drums & Barrels

Traffic drums & barrels bases are especially designed to manage the highways under bad conditions. You can place them on roads to hold traffic signs, safety drums/barrels in their right position.

With control over your workers and machines movements, they provide you safety at your construction sites. Its rubber base grips the surface well wherever you place it. Jackwin engineers use warning and reflective tapes that can shine brightly at night.

Rubber Traffic Cones

If we talk about rubber traffic cones, it is used for people and their automobile protection worldwide. Safety officers can install them on roads to manage the flow of traffic.

Furthermore, you can set them at your worksites, footpaths & school gates. Lightweight and gravity traffic cones are available. Different types of traffic cones have unique advantages. Hence, you can choose as per your needs.

Rubber Wheel Stoppers

It is a good idea for you to use wheel stoppers in your outdoor parking lots. It will keep your vehicles from going too far. You will also see them in business garages and commercial plazas.

Due to their weather resistance ability, they can do their job in all types of conditions (even when it rains). In the market, there are lighter and heavier wheel stoppers available.

Corner Wall Protectors

You should set up corner wall protectors in your work areas. Because, it helps your walls, machines & equipment stay safe from bumps/hits. They are great for your parking garages, factories and warehouses.

These protectors are made from tough materials, so they can handle strong impacts too. You can also see them easily because of their bright color. They work well both inside and outside and don’t need much maintenance.

Rubber Base Weights

Rubber bases weight are helpful tools in your rubber base weight applications, such as your construction sites, parking areas, and outdoor events. So if you are setting up traffic signs, curtain stands/stage barriers, these bases help everything stay stable & upright as well.

We offer you a wide range of rubber base weights. They all can well fit with your traffic panels and display signs. Additionally, in busy zones, they can hold your tools strongly and ensure they don’t fall.

Curb Ramps

If we talk about curb ramps, you will generally spot them at repair shops or when roads and walkways are under construction. Plus, if you need to temporarily use curb ramps, they are the best option because you can move them from one location to another.

JACKWIN engineers made curb ramps according to standards and regulations so that you can get maximum protection with good quality, too.

Wheel Chocks

Wheel chocks are wedge-shaped blocks that you can place behind & in front of your vehicle tires. They are also a fit choice for your warehouses, garages, docks and airports.

Heavy duty wheel chocks are light but strong enough to do your jobs. It functions efficiently with your large sized cars and aircraft.

Conclusion

To summarize, we can say all categories of rubber raw materials have their own unique properties. You can only achieve your desired result, if you carefully choose the right material. So, the Jackwin team suggests you always consider temperature/chemical resistance, quality & cost too.

If you need further expert advice you can contact our team today. We also offer a wide range of rubber-made products available in our Chinese factory.

-80x69.png)