When you drive on highways or go around construction sites, you may notice bold fences on roads. They are actually safety barriers.

They guide people & protect your heavy machines as well. This provides safety to the public. Today, you will explore why safety barriers are important, their applications and the main regulations you need to know & follow.

What Are Safety Barriers

Safety barriers are physical devices that you can use for the safety of the public. To fulfil this purpose, these devices are placed at different places like on roads, parking areas, in warehouses and workplaces. Basically, this gadget separates the restricted or hazardous area. It also guides the public about those things which are necessary for their protection.

Materials Used in Manufacturing of Safety Barriers

Different types of material are used in the manufacturing of safety barricades. Usually, steel, plastic and concrete are famous in the market. These materials are utilized according to your specific demands.

For example, if you want to install the barricade only for temporary usage, then plastic barriers are most suitable due to their lightweight nature. On the other hand if your choice is a strong, durable and permanent safety solution, then we recommend you to go with steel and concrete security railings.

Major Features of Safety Barriers

Strong and Tough: Strength is the basic need of each security device. All the safety barriers can easily absorb strike pressures.

Durable Material: They are manufactured with steel, concrete and plastic. So that they don’t break easily.

Customizable: Most fantastic feature of a safety barrier is that you can modify the shape or size of the fence according to your need.

Easy to See: Actually, the barricades are covered or painted with bright orange, red and yellow colors. That’s why the workers notice them quickly and take action.

Easy to Move: Most of the time, barriers come in parts. So you can shift them easily from one place to another. Moreover, plastic made barriers are lightweight to carry.

Hazardous Equipment: Sometimes, working or non-working equipment is also dangerous for human beings. This type of machinery is also protected by making a fence or barrier.

Suitable for Different Places: You can use these small devices at several places. Like in warehouses, workspaces, highways, construction sites, events and many more.

7 Types of Safety Barriers

-

Safety Fencing:

As its name shows, it is a strong steel or metal structure that is built to mark safe boundaries. Basically, used to cover up an area with restricted boards. You can even customize these fences according to your need and space.

-

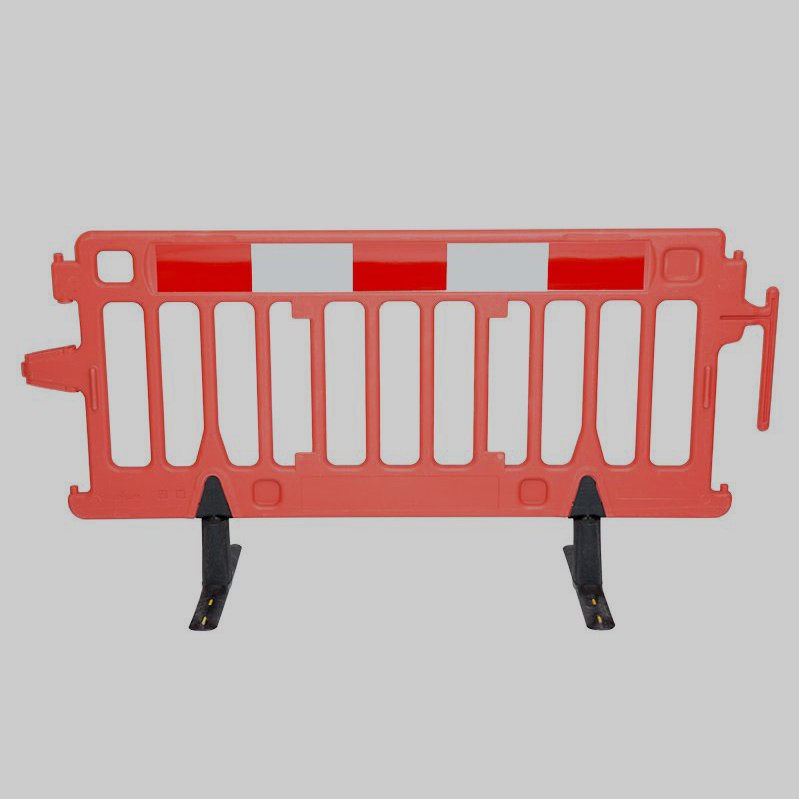

Traffic Barriers:

Traffic barriers are barricades that are specially manufactured for road safety. Generally, multiple types of barriers are installed on roads. Concrete, steel, plastic and aluminum barriers are used for this purpose.

-

Collision Barriers:

These barriers are unique in shape. Actually, these barriers are designed to stop or protect the car in case of collision or crash. The structure is prepared with very durable material with a strong base. This base is attached with the road to absorb a high amount of force.

-

Safety Bollards:

Vertical posts that you often see at roads or in events are bollards. The minimum height of this straight pole is roughly 36 to 48 inches. But you can change it according to your requirements. Main purpose of their vertical height is high visibility from a distance.

-

Safety Barriers For Doors:

Their purpose is clear from the name, safety of doors. Basically, these barriers are manufactured to protect doors from frequent use of trolleys, machinery and others. Mostly, they are 12 inches tall. But their maximum height can be approximately 5 meters or more then that.

-

Guardrails:

Guard rails are the barriers that are installed on the edges of roads. Actually, these barriers are placed in such a way that they also protect the sharp curves of the roads. Steel, metal or concrete is used to make these strong railings.

-

Racking Protectors:

Warehouses are the main places where this type of barrier is used. Because these barriers are designed to protect the racks system from forklifts, trolleys and other moveable machines. Usually, U and L shaped barriers are used in an upright direction.

Applications and Purpose of Safety Barriers

A wide range of industries use different kinds of safety barriers according to their specific needs. Below is a short explanation of its applications;

Accident Prevention

To reduce the risk of accidents, it’s very important to separate people from working areas. Safety barriers block the area which is not secure for the public like busy streets and industrial zones.

Fall Protection

If you work at heights and drive on open ended roads, it increases the risk of fall downs. To prevent such a situation, guardrails are used on the sides of roads. As they protect drivers and pedestrians from falling off. These barriers are made up with super strong materials like concrete and steel.

Traffic Control

Organized traffic flow is the basic need of each country because of road accidents. Barriers guide drivers about road situations and also separate the lanes. Actually, these lanes are divided for forklifts, trucks, cars, pedestrians and bike riders.

Machine Safety

As you know, some machines are very dangerous during operation hours. Hundreds of accident cases are reported due to machine injury. To control such a situation, these machines are also blocked with barriers.

Access Control

Not every area is secure for everyone! Many areas are dangerous for people. For instance, the area with the impact of radiation is super dangerous for each individual. Different types of safety barriers or bollards are used to control access to these areas.

Emergency Evacuation Routes

During emergency conditions a clear and safe path is the basic need. For the fast evacuation process, strong rallings are used to guide the public. Barriers also ensure that the path is blocked or not and safe or not.

Compliance Regulations That You Should Follow

If you are an engineer, retailer or security officer, it is your responsibility to follow these laws to minimize the risk for workers, drivers and the public.

According to OSHA parts 1910.23 and 1926.502, security standards are different for several types of barriers, such as:

- Temporary barriers used in construction should be 39 to 45 inches tall. It should support at least 150 pounds.

- If you want to place standard railings, it must be 42 inches high and able to hold 200 pounds.

- You have to install safety barriers where there is a fall risk. For example: edges of platforms, stairs, roofs and near machines too.

- Plus, barriers should be smooth with no sharp parts. Also consider that they should be manufactured in a way that people can’t slip and climb over them.

Under the PAS 13 code of practice:

- You need to test the barrier by certified tools and methods. Further, results must have a 5% safety margin. So that barriers can perform in real accidents as well.

- You must use safety barriers to separate the pedestrian and vehicle path. It becomes compulsory if both zones are less than 1 meter away from each other.

JACKWIN Tips For Maintenance and Inspection of Safety Barriers

Well, Jackwin is the top supplier of safety products in China. We have spent 18 years in the safety equipment manufacturing industry. Hence, according to our experience, you should follow these instructions to maintain the condition of your barriers.

Regular inspection: You should check your barriers regularly. If you see any signs of damage and wear, immediately fix it. This will help you to identify issues before it creates serious problems for you.

Proper cleaning: If you remove dirt and debris, barriers can stay long. Because, this clutter can cause damage & minimize visibility of barriers.

Secure loose parts: Well, operators also need to tighten any loose bolts or screws on the barriers. So that they can stay stable and don’t move when used.

Document Maintenance: We also recommend you to keep a detailed record of all inspections and repairs. The reason is it will help you to take guidance about repairs in future.

Wrapping It Up

We hope now you are clear about safety barriers that they are not only protective tools, but also lifesavers. Plus, they have a major role in safety of vehicles, machinery and less risk of accidents.

However, we will advise you, for maximum results, you must pick the right type and follow the regulations. You should place them at the right place as well. In this way, you can keep everyone safe at their work and jobs.

-80x69.png)