The reflective sheet is a commonly used material in the manufacturing of traffic signs and several other traffic regulatory products. Though there are plenty of material options available in the market, knowing what reflective sheeting is and its impact on road users’ safety is crucial.

This comprehensive guide is especially structured for you to explain everything that there is to know about reflective sheeting, such as reflective sheeting’s role in traffic signs and other products, its types, common uses, and much more. So, let’s dive in.

What Is Reflective Sheeting?

Reflective sheeting is a special material, well-known for the high-to-super level retroreflective property of bouncing light back to its source. Especially in low-light conditions, it enhances the visibility of the product to which it is applied.

Manufacturers globally leverage reflective sheeting for manufacturing traffic signs, road markings, safety jackets, traffic barriers and many other products to further enhance the equipments’ appearance.

However, it’s crucial to understand the working of retroreflective vs reflective. Reflective meaning is to bounce back light to all directions, while retroreflective is the process of bouncing back light directly to light source.

Why is Reflective Sheet Used?

The aim of using reflective sheeting is only to enhance the visibility of certain equipment. Common applications of reflective sheeting include traffic signs, vehicle markings, road cones, safety vests, and construction gear. Noticing this safety equipment on roads is extremely crucial for road users to ensure their safety.

Compared to other sheeting options available in the market, reflective sheeting is durable, cost-effective, easy to apply, a compliant option, and has a high-intensity retroreflection property that lasts for years.

How Does Reflective Sheeting Work?

Reflective sheeting works following retroreflection, which is a process that redirects light back toward its source (usually headlights). This redirection happens due to mini glass beads or microprisms that are embedded within the material.

When light hits the surface, these elements bend and reflect it straight back, which in a result, catches the driver’s attention and makes the object (or printed guidelines) appear bright and easy to see, even from a long distance.

Reflective Sheet Material: What is Reflective Sheeting Made of?

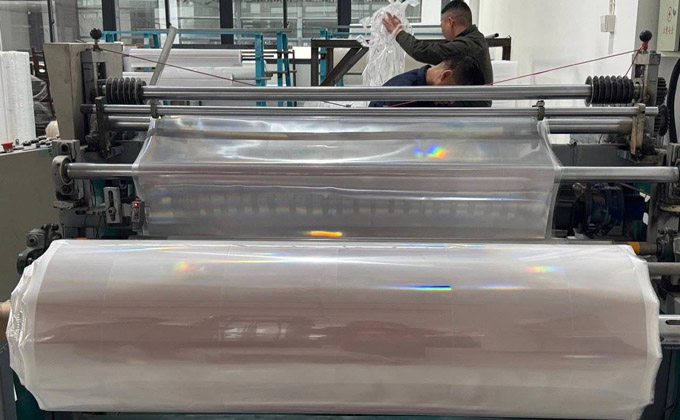

The reflective sheeting is made through thousands of glass beads, encapsulated lenses, or micro prisms reflective material that are embossed on a PVC/PET/PMMA/PC base sheeting layer.

But if you ask, how is reflective sheeting made? First, a flexible plastic film is taken as a base layer. On top of the plastic base, a thin aluminum or silver layer is added to which retroreflective glass bead, encapsulated lens ,or microprim material is added.

Lastly, a transparent coat is applied to secure the sheeting layer from fading and scratches. To some reflective sheeting, an adhesive layer is also added so that the sheet can be easily applied to traffic signs, jackets, helmets, barriers, or vehicles.

What is Reflective Sheeting for Traffic Signs?

Reflective sheeting for traffic signs is a material applied on top of the traffic signs’ aluminum surface. This sheeting makes the traffic signs more visible in dark and low-light conditions. By bouncing back vehicle headlights directly to the driver, traffic signs stay visible to drivers and hence, ensure their safety.

Non-reflective sheeting, compared to reflective sheeting, makes traffic signs disappear in the dark and is tough to spot from a far distance. That’s why reflective sheeting is a must to apply for traffic signs, stop signs, warning signs, highway markers, directional boards, to stay compliant with the MUTCD.

What Are the Different Reflective Sheeting Types?

As per the ASTM D4956 standard, reflective sheeting has ten types, which are categorized under two categories: Retroreflective Bead Sheeting and Micro Prismatic Sheeting.

Retroreflective sheeting is a material that reflects light back to its main source. Whereas, Prismatic sheeting material provides a high to super level of reflective and luminance properties.

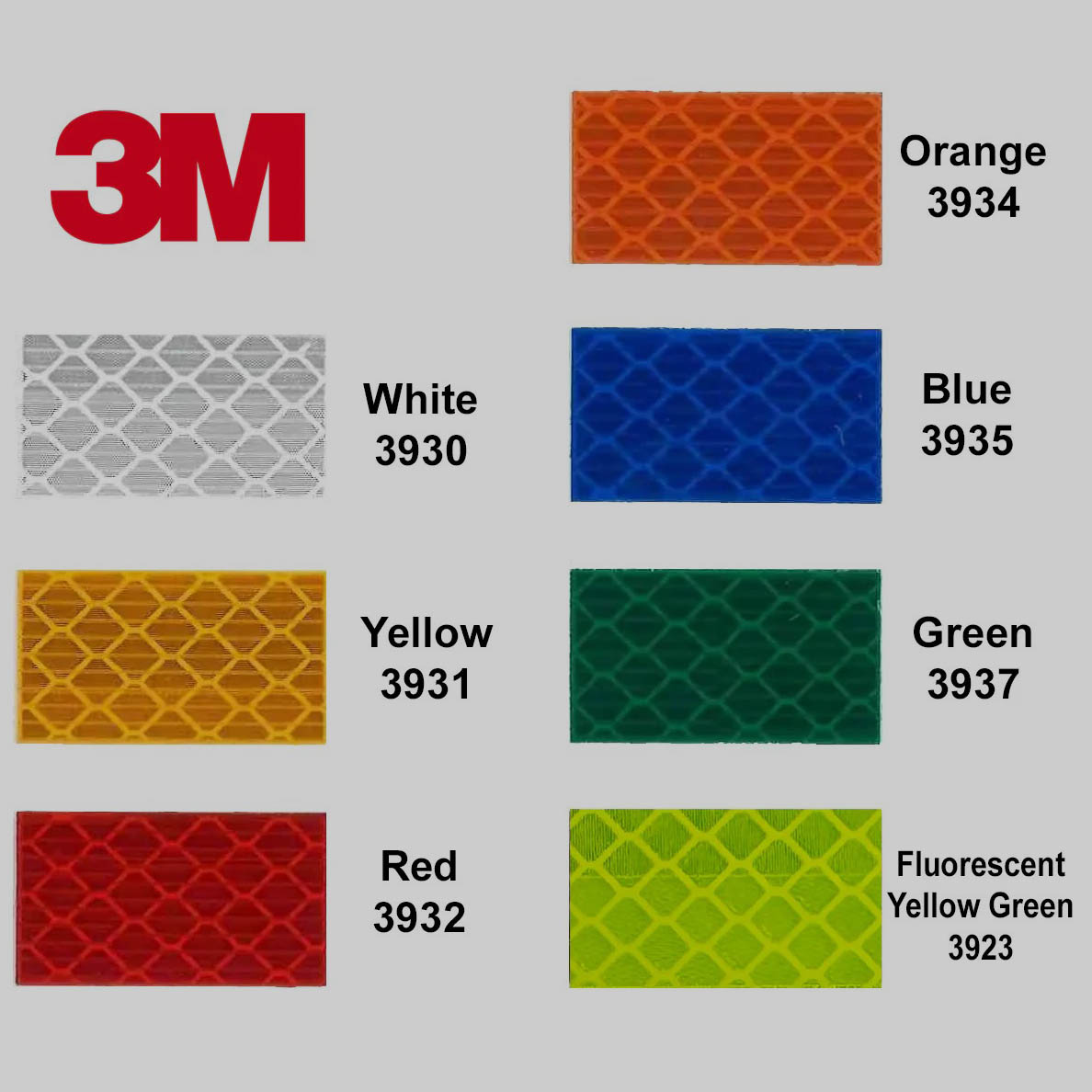

JACKWIN is the qualified agent of 3M reflective sheeting. Here are the types and varieties of reflective sheeting we offer:

-

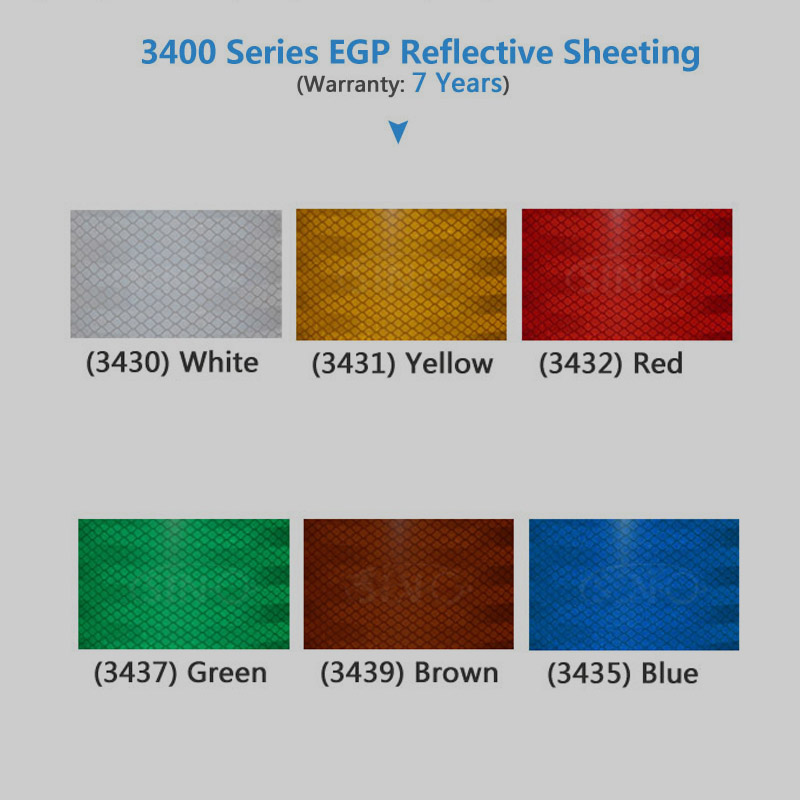

3M Engineer Grade Reflective (EGP) Sheeting

This is the basic level of 3M reflective sheeting, which is mostly used for non-critical traffic signs that are used in low-visibility areas. It offers decent reflectivity, making traffic signs easy to read in night visibility, but it is not as bright as the higher grades.

Engineer Grade typically uses glass bead technology, and Jackwin offers a 7-year warranty for this material. You can utilize this material to manufacture traffic signs for low-speed areas or where high reflectivity isn’t the main concern.

-

3M High-Intensity Prismatic (HIP) Grade Reflective Sheeting

HIP has more reflective and brightness properties compared to EGP. HIP is made up of micro-prismatic technology, making it way brighter even in sunlight and more durable.

You can use this sheeting for critical signs such as regulatory signs, warning signs, and any location where visibility is important, especially on high-speed roads and commercial areas. HIP sheeting reflects light at wider angles and lasts around 10–12 years.

-

3M Reflective Sheeting Diamond Grade (DG)

This is most reflective and brightest of all. It’s ultra-bright and designed for use in high-volume and fast traffic areas. You can use this sheeting to manufacture critical traffic control signs such as stop signs, speed limit signs, and guide signs on highways.

DG uses full-cube prismatic technology, which reflects almost 100% of incoming light, making traffic signs completely visible from far distances and sharp angles. It’s also designed in a way to last over 12 years, even in harsh weather.

-

3M Commercial Grade Reflective Sheet Sticker

This is a cost-effective reflective option that can be used for non-regulatory signage, decals, and general-purpose reflective needs. Though it has no comparison with EGP or HIP in terms of brightness and durability, it’s still an ideal choice for use to make a certain product highly visible.

You can use our commercial-grade reflective sticker for short-term indoor or outdoor use and apply it on labels, helmets, safety gear, and small signs to achieve the basic reflectivity. From us, you can also get stickers with the printed text on them.

If you’ve any queries regarding reflective sheeting, contact us now to get personalized guidance!

What is Reflective Sheeting Used For? Common Applications Explained

Reflective sheeting can be used in many ways and in various fields. Here are the most common applications of reflective sheeting:

- Traffic Signs

For years, facilities have been using reflective sheeting on traffic signs and even on other traffic products to improve the visibility of signage boards, for both day and nighttime so drivers can read them clearly and stay protected. Several other traffic products, like traffic cones, road barriers, and delineators, also include reflective sheeting.

- Construction Zones

At construction zones, facilities use cones, safety barriers, and traffic drums to warn drivers that there’s ongoing construction ahead. They are also used to create barriers between road and worksite to protect workers.

- Safety Clothing

Reflective tapes are also used and sew on safety vests, shoes, backpacks and jackets. The reflective part ensures the wearer stays visible to vehicles from a distance, especially at night.

- Emergency Vehicles

Ambulances, fire trucks, and police cars also have reflective sheeting thoroughly applied. Though the siren of these vehicles is enough to alert people, considering other factors, reflective sheets are used to improve visibility and reduce road accidents.

- Commercial Vehicle Markings

Reflective tapes are also used in commercial trucks and trailers as they are required to have reflective markings to improve their visibility on highways and during parking.

- Exit and Emergency Signage

Reflective sheeting is also used in buildings and even on exit roads to guide people safely during a fire drill or power outage. These signs stay visible 24/7 even in complete darkness.

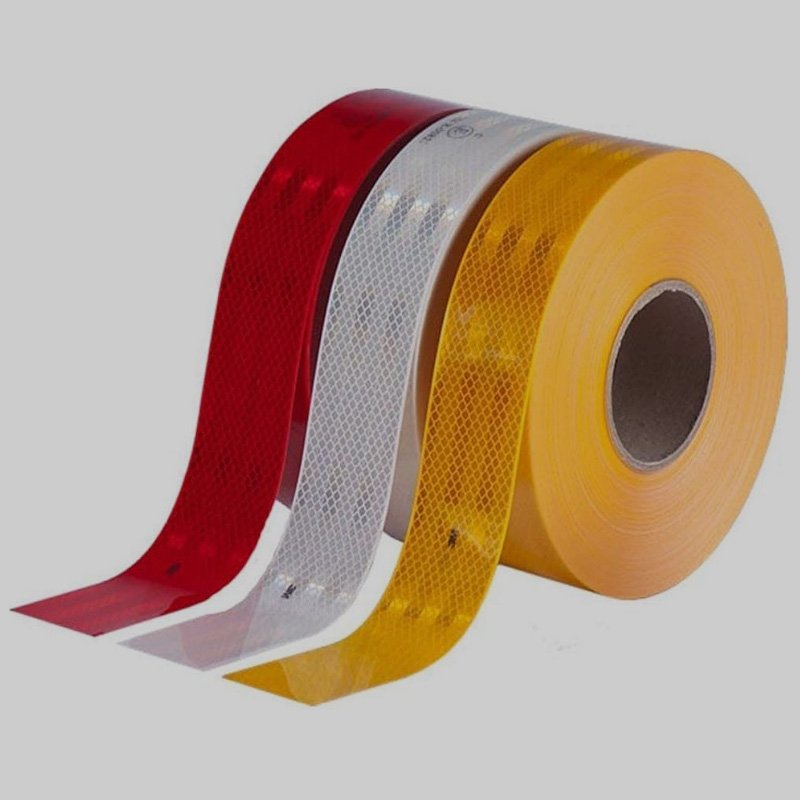

What is a Reflective Tape?

Reflective tape (often known as conspicuity tape) is an (adhesive or non-adhesive) material that reflects back light and shines brighter, making the vehicles/ safety tools more obvious on roads and reducing accident risks.

JACKWIN offers a wide range of reflective tapes. Our SASO 2913, approved by the Saudi SASO department and Vehicle Safety Center, is especially designed for use on vehicles to improve vehicle visibility and reduce traffic accidents.

You can also choose between reflective sheeting rolls for collars and traffic cones and retroreflective tape for sewing reflective safety vests & jackets. On customer demand, our professional team can also customize reflective tapes based on your requirements.

What is Reflective Tape Used for?

Reflective tape (often known as high-vis tape or glow-in-the-dark tape) can be utilized for highlighting the appearance of an object and for traffic safety tools. From jogging shoes, traffic cones, safety vests, and vehicle labels, to marking dangerous areas, it can be used where there is a need to improve visibility.

What is Reflective Sheeting Vinyl?

Reflective sheeting vinyl is a flexible, durable, and self-adhesive material, coated with either glass beads or prismatic material that lights brighter when hit by a light. JACKWIN reflective vinyl sheet meets ASTM D4956 Type I, especially designed for commercial use with self-adhesive backing for quick applications.

Compared to 3M 680 film, Jackwin reflective black sheet vinyl provides the same performance, functionality, and durability of 7 years without peeling and fading. It comes in rolls and you can use it for traffic and road signs, vehicle graphics, advertising boards, reflective logos, or signs.

What Is the Reflector Sheet Price in the Market?

The reflector sheeting (also known as reflective sheeting) price may vary depending on grade, thickness, quantity, and brand. For instance, 3M High-Intensity Prismatic (HIP) reflective sheet roll is generally priced around $115 to $120 (typically 3 inches by 50 yards). The price for 3M Diamond Grade (DG³) reflective sheeting can go up to $700 or more per roll.

But if you want reflective sheets at wholesale prices, you should deal with reliable reflective sheet manufacturers like Jackwin that deal at competitive factory prices.

Can You See a Reflection Sheet Sample Before Buying?

Absolutely yes! JACKWIN understands the importance of using the correct reflective sheeting material for traffic signs and other products. That’s why we provide customers with an option to get a reflection sheet sample only at US$ 20/Piece before purchase, so you can check the quality, color, and reflectivity before placing a bulk order.

What is Reflective Sheet Insulation?

Reflective sheet insulation is a radiant-heat blocking material that reflects almost 95% of the heat and stops it from entering the protected area. It can be used on walls, ducts, HVAC systems, and outside of the buildings to stop heat from entering the building. This can even be applied inside the building during winter to store heat within the building.

What Are the Reflective Sheeting Standards?

The official and globally followed reflective sheeting standards is ASTM D4956. This standard has specified guidelines for each factor, covering the performance requirements, testing methods, color coding, types, and classification, to specifications for retroreflective sheeting materials used in traffic regulatory devices.

In addition, there are also plenty of guidelines for traffic signs available in EN 12899-1, which is a European standard that also specifies performance criteria for the retroreflective materials used on traffic signs in European countries.

Where to Find Reflective Sheets for Sale?

JACKWIN is one of the leading China’s reflective sheeting manufacturers and wholesale suppliers that also supply sheeting of other famous reflective sheeting brands: 3M, Nikkalite, Avery Dennison, ORAFOL, TM, and DM.

We offer all types of reflective sheeting that comply with ASTM D4956, D8514, and EN 12899-1 standards. Whether you need Engineer Grade, High-Intensity Prismatic, or Diamond Grade, just name it and we deliver it to your location.

In addition, we also provide 3M 610C commercial-grade reflective tapes, reflective stickers, retroreflection sheeting and reflective vinyl sheet. We have a large stock available. Contact us today to get an instant quote.

What Is Reflective Sheeting HS Code for Import or Export?

39209959 is the reflective Sheeting HS Code for Import or Export. This HS code is specifically used for materials that are non-cellular and not reinforced, such as textiles, reflective sheets, films, stickers, foils, strips, and rolls.

While purchasing these products in global trade, using this code is vital to avoid customs delays, incorrect duties, or shipment issues.

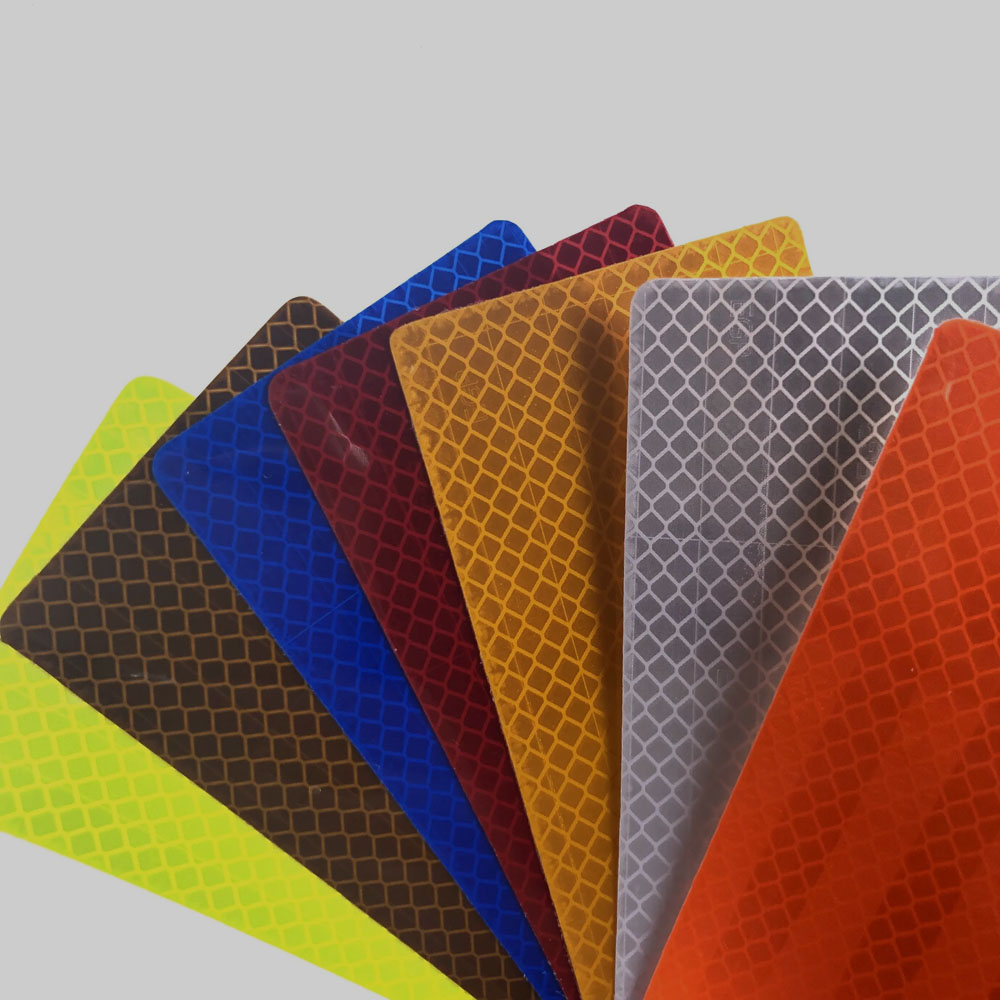

Reflective Sheeting Colors

JACKWIN supplies reflective sheeting in a variety of types, materials, widths, lengths, and colors. Our company supplies retroreflective sheeting in various colors, including:

- White

- Yellow

- Red

- Blue

- Green

- Orange

- Lime green

- Fluorescent orange/green

- Black

- Brown

- Pink

Conclusion: Your Reliable Reflective Sheeting Partner

One-stop solution for traffic safety products and reflective sheeting, tapes, and stickers, JACKWIN has been manufacturing and supplying for more than 15 years. As an all-in-one reflective sheeting solution, we offer a huge variety at competitive wholesale prices.

To order customized or 3M reflective sheeting, contact us today to get an instant inquiry. We also supply reflective sheeting of other famous brands like Nikkalite, Avery Dennison, ORAFOL, and DM.

-80x69.png)