JACKWIN Manufacturing Capacities

JACKWIN is one of the leading reflective road studs manufacturers and suppliers in China. We have been engaged in the research and development, production and wholesale of reflective road studs for more than 15 years. 95% of our products are exported to various countries and regions around the world. Our factory has plastic injection molding, electronic assembly and metal stamping processing workshops.

- ISO9001 & ISO14001 quality control system.

- Factory area over 5000 square meters.

- Supply OEM and ODM services.

- Small MOQ and fast shipment.

- Smart payment methods.

- 2-year quality warranty.

Reflective Road Studs for Sale

JACKWIN provides premium reflective road studs made of plastic, aluminum, glass, and ceramic at low factory prices, available in colors including red, yellow, blue, green, and white for your choice. Our reflective road stud can withstand loads of 20 to 50 tons, with a reflective brightness of 500 MCD. It is easy to install and remove, saving significant labor costs for your project.

Reflective Road Studs by Feature

Size 140x60x15 mm, made of ABS material, glass cat’s eye diameter 10mm.

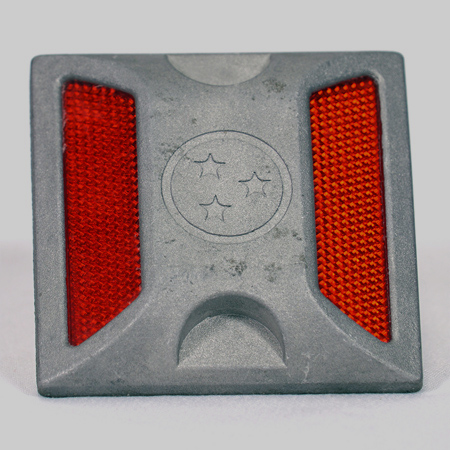

Made of ABS material by injection mold tooling, with a high-visibility reflector on both sides.

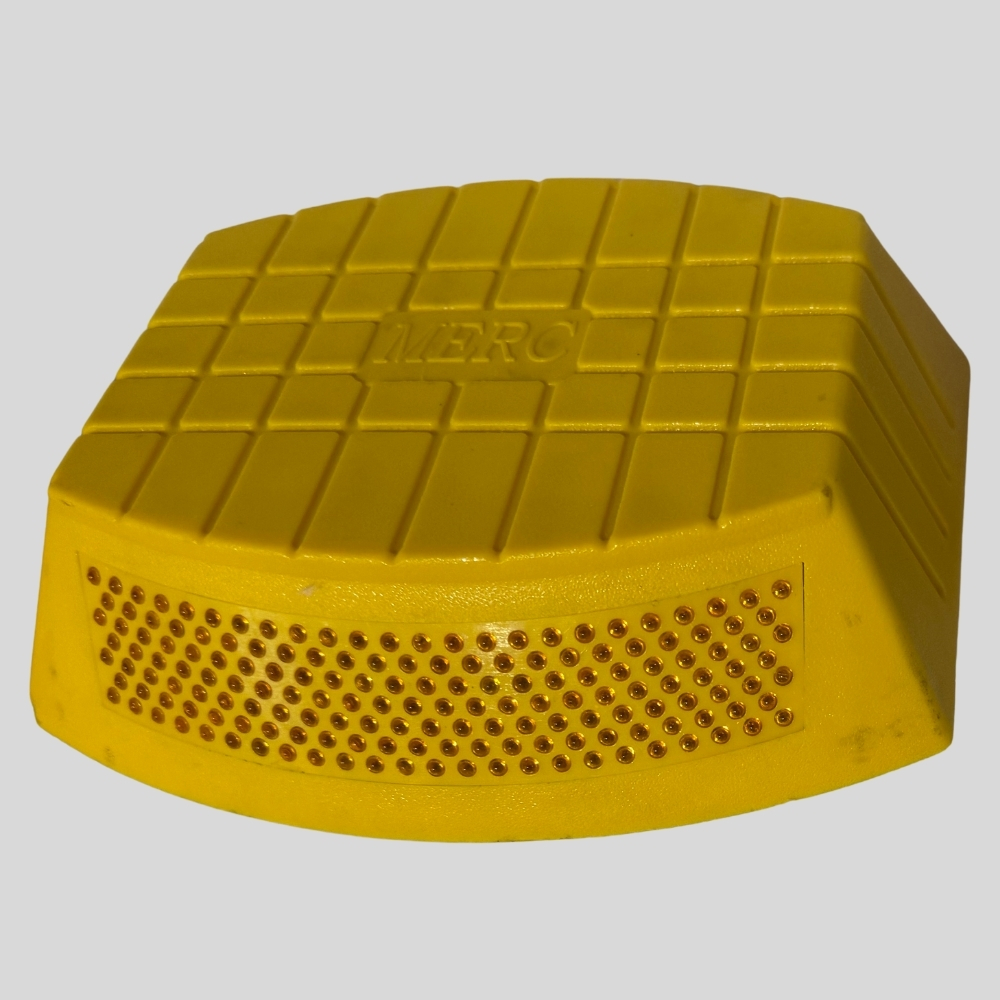

Size 240x150x50mm, 780 grams with 2 steel pins, with glass bead reflectors.

Designed for South America markets, made of ABS material with big cat’s eye reflectors.

Size 200x180x50mm, glass beads, 970 grams with 4 steel pins, weight capacity 50 tons.

Size 100x100x20mm, made of ABS material, 0.15 kg, bolt Ø1.4 H7 x 0.8 cm, 3 glass reflectors.

Size 100x100x20mm, made of ABS with fluorescent materials, glow-in-the-dark.

Size 100x100x20mm, made of ABS material for housing and PC lens reflectors.

Original 3M reflective plastic road studs, available colors in red, white, and yellow.

Made of casting die aluminum alloy material with amber reflectors on both sides.

Mini tempered glass cat’s eye, diameter 2 inches, with rubber holder outside.

Made of tempered glass, with silver coating on backside, high reflective with 30 tons capacity.

Diameter 100mm, made of ceramic material with glass beads and plastic reflectors for options.

42 glass beads reflectors, made of casting die aluminum alloy with spike, capacity over 30 tons.

Size 100x100x20mm, with spike, 2 reflective panels.

- Manufacturing Process and Steps

- Reflective Road Studs Rules and Regulations

Reflective road stud manufacturing steps are divided into plastic reflective road studs, cast aluminum reflective road studs, glass road studs and ceramic road studs. Their production processes and steps are completely different.

- Plastic reflective road studs are produced using the injection molding process. Plastic housings are made of ABS, and reflectors are made of PC or PMMA material by injection molding.

- Cast aluminum reflective road studs use the cast aluminum process, and reflectors are also produced by injection molding.

- Glass reflective road studs utilize a heating glass material to shape it, and then temper it to increase its load-bearing capacity.

- Ceramic road studs use the ceramic firing production process and are equipped with reflectors.

- Reflective road studs must have a good reflective effect, which can be easily seen by drivers at night or in low-light conditions and arouse their vigilance, thus improving safety awareness.

- Colors of reflective road studs must comply with international standards and local regulations.

- Reflective road studs must have a strong load-bearing capacity, can be used on any roads and must be durable and not broken by wheels.

- Reflective road studs must be installed correctly. The direction of the reflector must face the direction of the headlights. The color must be installed on the road in the correct position according to the color code rules.

- Proper space distance must be maintained between each reflective road stud.

Reflective Road Studs Highway Codes

Reflective road studs on motorways, also known as “road cats eyes” in the UK, are mainly used in the middle of lanes of streets, highways and on both sides of the road to improve driver safety. There are different colors, such as red, amber, green, lime yellow, and white, which are used in different places on the road and have different meanings.

Below are the different reflective road stud colors and their meanings on motorways:

- White reflective road studs are installed in the middle of the road or used to mark lanes.

- Red reflective road studs are installed on the side of the lane to separate the left lane from the shoulder and mark the outline.

- Amber reflective road studs are installed on the edge of the median of a dual carriageway to separate the median and prevent vehicles from hitting the median.

- Green reflective road studs are installed at the edge of parking areas or turnouts.

- Green/yellow reflective road studs are used as temporary lane edge delineation markings during road construction.

Applications

JACKWIN reflective road studs are widely used in highways, expressways, urban roads, intersections, pedestrian crossings, school zones, and highway ramps. Browse the following use and learn more to get more thinking for your projects.

Reflective Studs Between Motorway and Slip Road

Reflective road studs are widely used on motorways and slip roads. They are particularly important at night or in low-light conditions. When illuminated by headlights, the reflectors of road studs will reflect dazzling light, forming a long outline of the motorway. When motorway turns or changes, the driver can react in advance.

Most slip roads are curved. Generally, drivers will slow down when driving on winding slip roads. At this time, road studs are particularly important. They can form the shape of the slip road under the illumination of headlights, so that the driver can adjust the position of the car at any time and maintain a safe driving state.

Our standard production lead time is 7-10 business days, depending on your order quantity.

The first cat’s eye was invented and patented by a British businessman and investor called Percy Shaw in 1934, and then a company was established to produce and sell it.

-80x69.png)