Road Marking Glass Beads Manufacturer

JACKWIN is a leading manufacturer and supplier of reflective glass beads in China. We in-house develop and produce various reflective beads used for traffic road marking, military, and industrial applications.

- ISO9001 & ISO14001 factory audited.

- Factory area over 5000 square meters.

- Bulk in stock and ready for shipment.

- Accept customization as per your requirement.

- Smart payment methods.

- 2-year quality warranty.

Supply and Wholesale Vaious Reflective Glass Beads

JACKWIN supplies and offers various types of reflective glass beads for traffic road marking paint, signs, and pavement marking tapes at competitive factory prices, and is exactly compliant with international standards and regulations of highway marking.

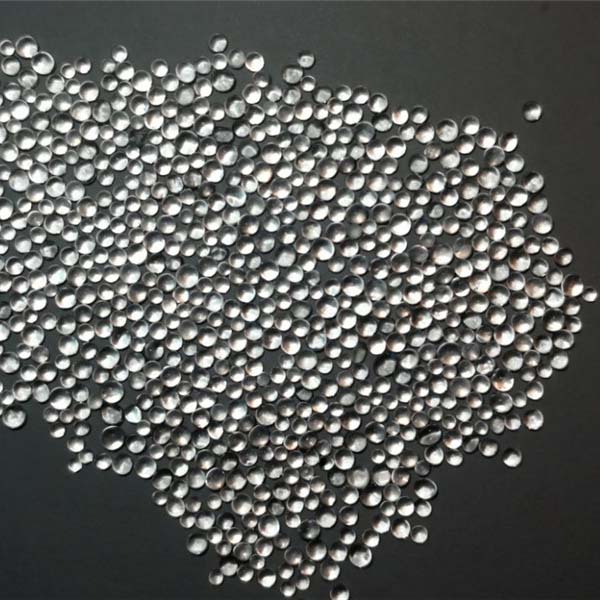

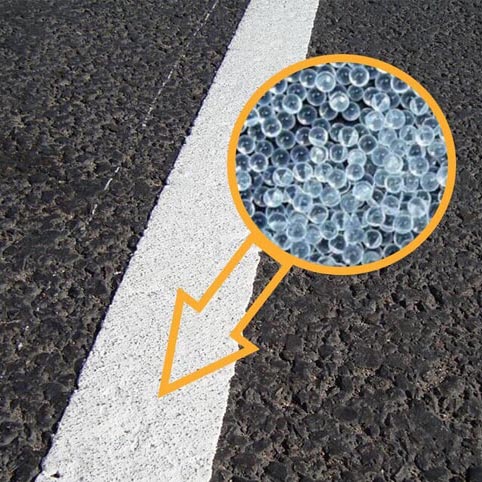

JACKWIN road marking glass beads, which are made from recycled glass(bottles, windshields), are used to increase the reflectivity of road marking paint, create outlines when road changes, and improve safety for drivers at night or in low-light conditions.

Reflective Glass Beads for Road Marking by Application

Customize various particle sizes of your requirements for thermoplastic road marking.

Drop on(Surface-Applied) glass beads used in normal temperature and hot melt road marking.

High quality and highly reflective for airfield runway marking of airport.

Made from reflective micro-crystalline ceramic beads, resistant to water.

Used for highway and thermoplastic road marking paint.

Used for road marking, curb painting, traffic, pavement, parking lots, crosswalks and driveways painting.

Offers various types of reflective glass beads for line striping at competitive prices.

Compliant to KSL 2521 Korean Standard, diameter 75-1400 microns.

Refractive index over 1.5, diameter range 600 to 1700 microns.

High visibility at night or in low-light conditions, durable usage.

Drop on surface, for road pavement marking.

Retro reflective glass beads, colorless and transparent.

- Glass Beads for Road Marking Specification

- Standard and Certifications

Component Table of Glass Beads for Road Marking Paint

| SiO2 | Na2O | MgO | CaO | Al2O3 | K2O | others |

| 71-73% | 13-15 % | 3-5% | 8-10% | 0.5-2% | 0.2-0.6% | ≤2% |

Reflective Glass Beads for Road Marking Paint Features:

| Features | Intermix Glass Beads | Drop on Glass Beads | High Index Reflective Glass Beads |

| Gravity | 2.4-2.6 g/cm³ | 2.4-2.6 g/cm³ | 4.2 g/cm³ |

| Refractive index | ≥ 1.50 | ≥ 1.50 | 1.9 – 19.3 |

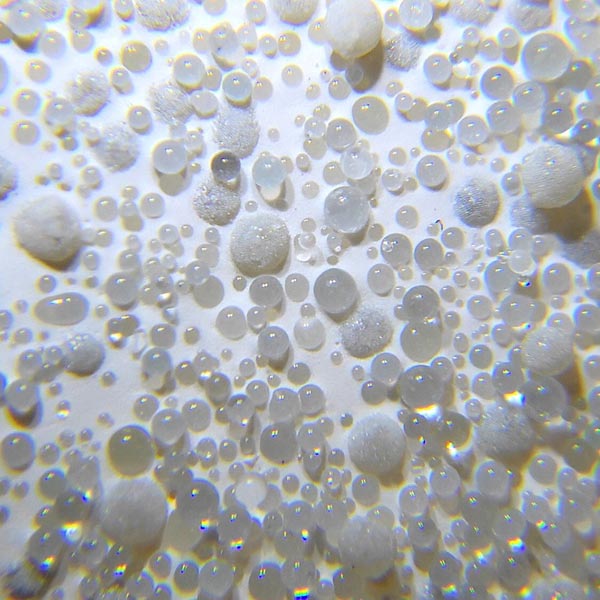

| Roundness | ≥80% | ≥80% | ≥90% |

| Magnetic particle content | ≤0.1% | ≤0.1% | ≤0.1% |

| Color | transparent, colorless | transparent, colorless | transparent, colorless |

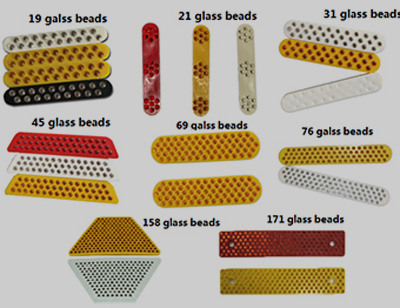

By Refractive Index (RI)

| RI Type | Reflectivity Level | Common Uses | Key Features |

| Standard (RI 1.5) | Basic reflectivity | Urban roads, parking lots | Cost-effective; complies with EN1423/AASHTO M247 31014. |

| High-Index (RI 1.7) | Enhanced brightness | Highways, expressways | Better light return; adhesive coatings improve durability |

| Ultra-High (RI 1.9+) | Maximum brightness | Airport runways, taxiways | Critical for pilot visibility; ≥1.9 RI; not for roads |

Standards and certifications for the main countries are as follows:

- EN1423/EN1424 (Europe)

- AASHTO M247 (USA)

- Type I II III, BS6088 (UK)

- Australian A, B, C, D

- KSL 2521 NO.1 and 2 (Korea)

Custom Glass Beads for Road Marking

We are a professional and leading manufacturer of high-performance glass beads for road marking and customizing various types and sizes of beads for paint, thermoplastic & cold-plastic in your project.

Why more than 200+ global contractors trust us?

✅ Tailored Solutions: From 150-800 refractive index, we customize size/grading for paint, thermoplastic & cold-plastic applications for your parking lots, signs, road markings, airport runways, smart city projects, highways, and urban roads.

✅ Durability Guaranteed: Low-alkali glass ensures weather/chemical resistance, reducing your maintenance costs by 45%.

✅ Supply Chain Excellence: ISO9001 and 14001 certified production with 25,000MT annual capacity. Our ocean/air shipping solution, optimized for 30+ countries, enables you to receive goods quickly and safely.

✅ High Performance: Our microspheres perform 360° reflectivity, enhancing night visibility and compliance with international standards (ASTM D1155, EN 1423/1424).

✅ Free Samples: We supply free samples for your testing. Please request technical consultation NOW!

Applications

Browse JACKWIN reflective glass beads used in many types of traffic paintings, signs, etc.

Glass Beads vs Crystal Beads

Crystal beads and glass beads are almost the same in composition, with glass as the main component. However, there are differences between them. Crystal beads are of high quality, high brightness, high density, and high refractive index, so they look more dazzling and clearer. Here are their differences:

Crystal beads:

- Material: Contains lead crystals, which contain lead oxide, which has better sparkle and clarity.

- Quality: Due to its excellent clarity, brightness and weight, it is of higher quality and more expensive than glass beads.

- Brilliance: Facets can reflect and refract light more effectively, and the reflective effect is better.

- Weight: Due to the lead content, crystal beads are denser and heavier than ordinary glass beads.

Glass beads:

- Material: Made from recycled glass.

- Quality: Varies greatly, related to the quality of the glass. Usually not as reflective as crystal beads, and lighter.

- Glitter: May not have the sparkle and clarity of crystal beads.

- Price: Affordable, with a variety of colors and styles, a large inventory, and a wide range of applications.

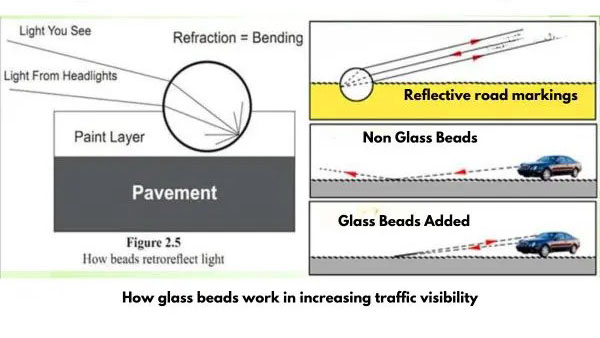

How Glass Beads Work in Increasing Traffic Visibility?

Reflective glass beads are a kind of spherical glass that is transparent and has the ability to refract light. So we use this physical property to apply it to traffic markings to improve visibility at night to prevent traffic accidents.

When the light from the car headlights hits the glass beads at a certain angle, the glass beads refract and then hit the surface of the glass bead cut surface. Then the refracted light will be reflected at a certain angle through the mirror surface to the driver’s eyes. The driver sees dazzling light. This is the working principle of glass microbeads.

-80x69.png)