As a civil engineer or roadwork professional, you should know the right process of road construction. So that you can plan better, avoid mistakes and build safe and durable roads for driving.

Today, we will tell you the simple road construction process and road building materials. You will also learn required highway paving machinery, challenges you may face during highway construction and their solutions.

What is Road Construction?

Road construction is the process of building new routes and repairing old paths. As an engineer, you must select suitable materials such as asphalt, concrete or gravel. It all depends on the type of path and traffic volume.

Basically, roadwork is an important part of modern infrastructure, towns and rural areas. That is why, you have to build a route which has a smooth surface, durable and safe for driving.

Road Construction Step By Step: Road Construction Phases

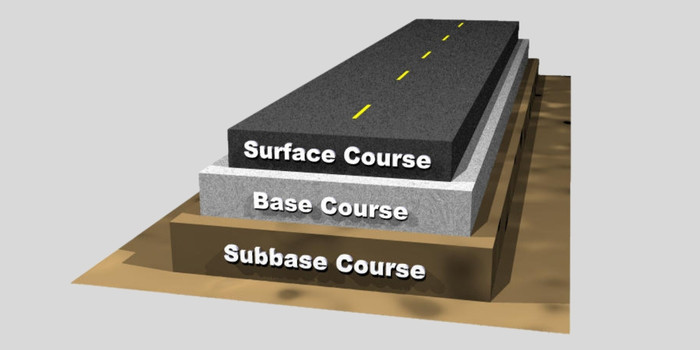

Building a road is not done all at once. Layers of roadway should be carefully constructed with the right materials and strong base. Following are the main steps of the road infrastructure process.

1. Base Course Layer Cleaning

First, you should fix the old road and remove rust from the surface. Also fix potholes or weak spots if you notice. Now, you can mix small stones with binder to fill surface gaps. This must be done about a week before you add top layers. In cas, the old road is very thin, you can place thick bitumen layer. This will make the surface even for next pavements layers.

2. Tack Coat Application

This is a thin layer of liquid bitumen. It is applied to create a stable base so the next layer of asphalt can stick properly. Because, the bitumen base or binder course acts like a strong foundation.

You have to use more bitumen for tack coat, if the base is not bitumen based. Generally, 6 to 7.5 kg is applied per 10 sq.m and for non-bitumen bases, this can increase up to 7.5 -10 kg.

3. Premix Preparation and Placement

The premix is a mix of asphalt and aggregates, which you can prepare in a hot mix plant. It is important to carefully heat bitumen & stones to maintain a temperature range of 150-177°C.

Then, you can transport hot mix with the help of trucks to the location. You must spread this mix at a temperature of around 121 to 163°C by the use of a paving machine. If you want strong roads, you should maintain proper heat during mixing, laying and compaction.

4. Rolling

Rolling step makes your drive surface smooth and removes air gaps too. After you spread the mix on the base, you must compact it by rolling slowly at under 5 km/h. You will need 8 to 12 tonnes of roller for initial rolling.

But for better compaction, you should use heavier pneumatic roller with weight of 15-30 tonnes plus tire pressure of about 7 kg/sq.cm. To stop the mix from sticking, you can spread water on roller wheels.

Furthermore, the number of rolling phases will depend on how thick the layer is. In warm weather, you should roll again the next day to make the road firm. Finally, a tandem roller of 8-10 tonnes can be used for smooth finishing.

5. Concrete Quality Check

You should regularly inspect the road surface to make sure that pavement and mix are strong and durable. As an inspector, you need to test things such as the quality of bitumen, aggregate heat and the temperature of the paving during laying & compaction.

For every 100 tonnes of material produced in the hot mix plant, you must test at least one sample. Additionally, you have to conduct marshall tests. You can also do a field density test for every 100 square meters to check that the road reaches at least 95% of the lab density.

6. Finished Surface Inspection

The last step of highway development is to examine the finished surface. Final inspection is required to check the road meets the traffic standards. You have to see the surface closely to see if it is smooth, even and free from cracks & holes.

Moreover, you can use special tools and machines to measure the thickness of layers, strength of the surface and overall quality of the street. If you notice any problem, you must repair it for safe vehicle movement flow.

Road Construction Materials

-

Soil

Soil is the base material for any type of road. Basically, it supports all the layers above it. The type and quality of soil decide how strong and stable your way will be.

Before construction, you have to check soil strength, moisture and its ability to hold weight. The reason is that good soil is ideal for paths that last longer and never crack easily.

-

Aggregates (Coarse and Fine)

In road construction, aggregates are one of the most important materials. They have two types: coarse aggregates such as crushed stones and fine aggregates like sand. Coarse aggregates give strength and stability to your routes.

While, fine aggregates fill gaps and make the mix compact. When you use both, they create a solid base. These aggregates are also helpful for binding materials like asphalt and concrete for smooth route surfaces.

-

Bitumen

Bitumen is actually a black and sticky material. It is used as a binder in road paving. This material holds all aggregates together and makes your path surface waterproof and flexible.

Due to its extreme holding strength and ability to resist weather, you can use it for highways, city roads and airports construction projects. In this way, you will have roads with a smooth finish for safe and comfortable driving.

-

Binders

In the process of road projects, binders act like glue that keeps all materials stable in an exact place. In addition, they improve the bonding between soil, aggregates and other road pavement layers.

You can use different binder such as cement, lime and fly ash. These materials reduce cracks and make the road surface durable against heavy traffic.

-

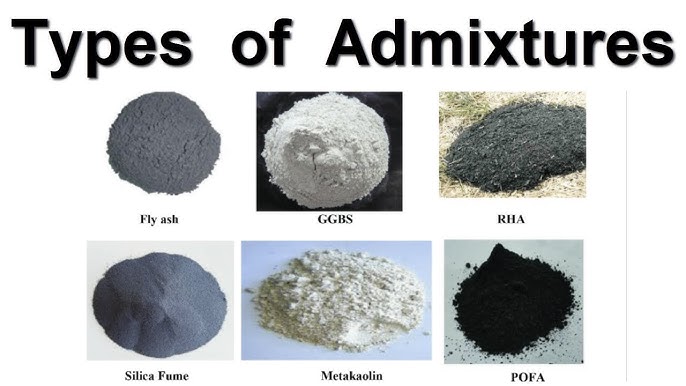

Admixtures

You must add admixtures with concrete and asphalt to improve their performance. Because, they can make construction mix strong, last long as well as you can set it fast.

Some admixtures provide the ability to road so they resist water. On the other hand, others improve flexibility and reduce cracking. This material is also beneficial for your road in a way that they can handle all traffic conditions better.

6 Stages of Road Construction

Planning

Planning is the first stage of the road work procedure. Civil engineering companies need to check how much traffic is on the highway now. Also analyse how much transport flow may increase in the future.

You should also compare costs with the benefits to see if the project is worth it. Money, legal rules & environmental problems must be studied early so you have a plan to solve these issues.

Design & Infrastructure

Design is the phase where the road’s shape, width and structure are actually decided. Surveyors visit the site and use modern tools to measure the road’s overall dimensions & design.

Also study the land, soil and nearby areas. This will best to see if you can expand the road later if needed. You must check water flow to keep the path safe and stable.

Earthwork

If we talk about the earthwork stage, it is the process of preparing the land for the road. You have to clear the land of trees, rocks and other obstacles.

In addition, you must examine the ground layer to see if the soil can carry the road’s weight. Weak soil should be replaced with gravel, sand and other materials such as cement/bitumen.

Paving Materials

You can choose the type of paving according to path use. For example: asphalt paving is best for highways and city roads. Because it is smooth and flexible.

However, concrete paving is used where heavy loads and long life are needed such as airports & industrial highways. If you select the right paving material, you can protect the road base from damage.

Quality Monitoring

Once a concrete route is built, you must check it before vehicles are allowed to use the road. Inspectors look at things like drainage and surface levels.

Also see how well the road reflects light at night. If you find that the road passes these tests, the path paving is considered finished and then you can open the way for traffic.

Maintenance

Well, the maintenance must be planned from the very beginning of road construction. Engineers design roads in a way that makes future repairs easy and less costly. You also choose drainage, materials and routes that reduce damage over time.

We can say, if you have a proper road maintenance plan, it guarantees safety and strong routes for many years after building.

Road Construction Machinery

There are several types of machines that you can use to make your road work fast, easier, and more accurate. Below, we explain some road construction equipment and their uses.

Asphalt Mixing Plant

You can use this machine to prepare hot mix asphalt for road construction. This tool combines bitumen, sand and aggregates in the right amount. For your big projects, you can place an asphalt mixing plant right at the work site.

Truck Crane

A truck crane is a vehicle which is fitted with a crane on top. You can use it to lift and move heavy materials such as pipes, beams and worksite equipment during road projects. Because, you can easily travel this machine to different sites and work where needed. It also reduces manual effort in handling large loading/unloading.

Motor Grader

Among all the machines you can use in road construction, the motor grader (road grader) is one of the most useful. It operates with long blades plus three axles. You can use it to level the soil, spread materials & shape the base of the highway. Also, it is best for making slopes and ditches for drainage.

Road Roller Machine

After you spread asphalt on the street then a road roller is required. This equipment presses and compact soil, gravel, asphalt and concrete. You can remove air gaps and make an even surface with its heavy drum pressure. Furthermore, you can also use it at different stages to make each pavement layer solid and durable.

Wheel Loader

It is a large machine with a wide front bucket. It’s helpful for you to lift, carry and load materials such as soil, sand, gravel or asphalt. While laying roads, you can also use it to move heavy materials quickly from one location to another.

Crawler Excavator

This machine is used for digging and earthmoving. Instead of wheels, it functions on trucks. In this way, it has a good grip on rough or uneven ground. With its help, you can also remove rocks, debris cleaning and prepare the land for building.

Forklift Truck

A forklift truck is a vehicle used to move heavy loads over short distances. It has two strong forks in the front. These slide under materials such as pallets, pipes and building supplies.

Road Construction Problems and Solutions

Following are major road construction hazards and their control measures.

- Environmental Issues: Pollution created during road work can harm nearby areas. You should spray water to control dust and also manage waste properly.

- Traffic Management: If vehicles are moving near your site, it can cause jams and accidents. To solve this issue, you can place traffic signs, barriers & flagmen to guide traffic safely.

- Impact on Local People: During road work, noise, blocked paths, and dust can disturb residents. You must provide alternate paths so pedestrians can move easily.

- Sharp-Edged Objects: Things like nails, glass & tools which present around the site can injure your workers. Provide them safety boots/gloves and clear surface regularly.

- Fast Moving Vehicles: If vehicles are moving too fast near your construction area, they can accidentally hit workers. That is why you should install speed bumps or breakers around the site.

- High Temperature: Hot asphalt & heat can cause burns. You should provide protective gear, shade and regular water breaks for workers.

- Chemical Hazards: Bitumen fumes and other chemicals are dangerous to health. You must use gloves and have a proper ventilation system.

- Falls and Collisions: The risk of slipping, tripping, and getting hit by machinery is high at the construction site. Always remember to wear helmets and follow workplace safety rules at any cost.

To Summarize

Hence, we can say that if you want long lasting roads, you must follow a professional road construction process. We recommend you to choose the right materials carefully as well as apply proper quality checks.

If you need more details, you can contact us today. Our experts will offer you free guidance plus every kind of machinery for road or highway construction and traffic safety.

More Relevant Sources:

Leading Road Marking Paint Manufacturers and Suppliers in China

-80x69.png)