The construction industry depends mostly on tower cranes to lift & move heavy materials to high heights. That’s why we have listed major types of tower cranes in this article.

You must read it to know which one suits your project best. Plus, we have added safety precautions and protective devices information for you.

Tower Crane Classification By Structure

Top-Slewing Tower Crane

This type of crane has a vertical fixed mast to provide height. A slewing unit is located on its top. This unit allows the horizontal jib (arm of the crane) to rotate 360 degrees. You might see a trolley that moves along the jib to carry loads.

Uses: You can select it if you want to move heavy loads on high-rise buildings. Especially when you have limited space or a crowded area.

Hammerhead Tower Crane

When it comes to a hammerhead tower crane, its jib or arm stays horizontal at all times. Basically, the trolley moves back and forth to move your heavy material. Therefore, it is a more stable option for you.

Our advice: Ideal to lift heavy material on large construction and industrial sites where there is more open space.

Luffing Jib Crane

Well, this crane has a jib that can move up and down (vertical lift) instead of a fixed horizontal movement. So, you can use multiple cranes on a single site without risk of collisions. But you have to install some safety devices like zoning devices for safe operations.

Applications: You can choose it for congested urban sites and closely spaced buildings.

Self-Erecting Tower Crane

As its name shows, you can assemble this crane quickly on the site without any external help because it has a hydraulic system. Furthermore, it has a shorter mast and a horizontal arm that can rotate from the base.

Use case: The whole unit is compact, easy to transport and ideal for projects that need quick setup and relocation.

Flat Top Tower Crane

A Flat Top Tower Crane has a compact head and a horizontal jib. Which means you do not need a top anchoring system to move the material. As in a luffing jib crane, its flat design lets multiple cranes work close together. Moreover, its modular structure allows quick assembly and disassembly.

Application: You can buy this crane for tasks where several cranes operate closely.

Tower Crane Types According To Functions

Construction Tower Cranes

These cranes are the most common type used in building projects. They have a tall mast, a rotating jib and a counterweight system that keeps them stable. You can find them on almost every major construction site because they reach great heights and carry large loads with ease.

Applications: You might prefer this crane to lift steel, concrete and heavy materials in large building and infrastructure projects.

Static Cranes

Static means these cranes are fixed in one position and do not move around the site. Usually, they have a strong base that always remains static and a vertical mast. Some models can slightly move the jib.

Use: It allows you to lift heavy materials repeatedly in one fixed spot on a construction site.

Fixed Mast Tower Crane

A Fixed Mast Tower Crane is a large crane with a tall vertical mast. Basically, it stays in one place throughout the task. Its jib moves on the site to transport weighted objects.

Application: You should select it for long-term and heavy-duty lifting on high-rise buildings and industrial sites.

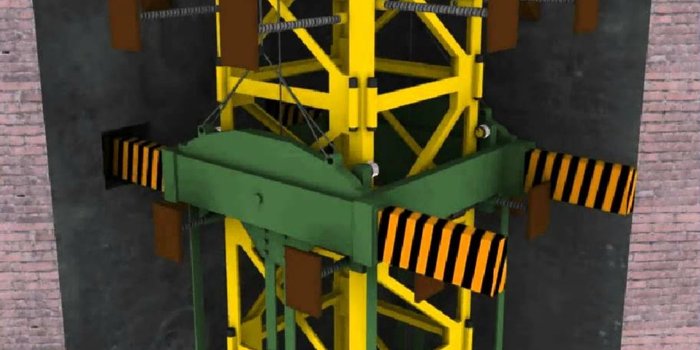

Internal Climbing Tower Crane

This unique crane is designed to climb up inside a building as construction progresses. Basically, it is attached to the structure or building. After that it uses a hydraulic system to raise itself floor by floor.

Applications: You can lift and place materials safely as your building grows taller.

Level-Luffing Cranes

In this type of crane, the main hook remains at the same level. But jib moves up and down. Actually, this mechanism allows you to lift and place materials without changing their distance from the mast.

Use: Their precise control makes them ideal for port operations and shipyards where accuracy is crucial.

Tower Crane Safety Precautions

There are many organizations (OSHA and CPA) that set safety standards to work at construction sites.

- You need to inspect your crane before use, to find any sign of damage.

- Make sure your crane is properly anchored from the base.

- Only trained operators or qualified engineers should handle your crane.

- Before you start tower crane operation, a qualified rigger should design a rigging plan.

- Never try to lift more than your crane’s maximum load capacity.

- Keep your work area separate from unauthorized people and obstacles.

- Use proper signaling and communication when you operate the crane.

- Always wear your personal protective equipment (helmet, gloves, jackets, safety boots).

- Stop crane operations if you face high winds or severe weather.

- You should install proper sign boards to warn others.

- You must place cranes away from power lines or de-energize them.

Tower Crane Safety Devices

According to a report, previously 838 violations of rules were committed by workers. These violations killed 133 people. So, you have to follow safety rules and install these safety devices.

- Load Moment Indicators (LMI)

- Anti-Two Block Devices

- Wind speed indicator

- Crane limit switches

- CCTV cameras

- Collision avoidance system

- Emergency stop button

- Stability monitoring systems

Tower Crane Lighting Requirements

Tower cranes need red obstruction lights for aviation safety. Especially if they are above 150 feet (45 meters). The lights must follow FAA and ICAO rules. You need to regularly maintain them. Moreover, you should arrange a backup power in case of failure.

FAQs

How to Raise a Tower Crane?

You can raise a tower crane with the help of its hydraulic or climbing system. Plus, you are required to follow the manufacturer’s instructions and safety procedures.

What is Tower Crane Mast?

The mast is the tall vertical structure of a tower crane that supports the jib. It also allows the crane to reach high heights.

What is Safe Use of Tower Cranes?

Safe use of the crane mainly includes guidelines that you need to operate any crane. And its load capacity with safety instructions.

Final Note

We believe you learned all necessary things about tower crane types and their uses in different construction & industrial tasks. When you choose a tower crane, make sure it matches your site’s requirements (like height, space and load capacity).

We are a professional manufacturing factory in China. You can discuss your project with us and get high-quality workplace safety products or construction machinery.

-80x69.png)