Global polyethylene production reached 120 million metric tons in 2024. It makes up around 34% of all plastic markets around the world. One of the most popular types of polyethylene is HDPE that makes over 45 million metric tons.

The reason is that high-density polyethylene is used in many industries, such as construction & traffic safety. Today, we will tell you common uses of HDPE and why it is ideal to make durable products.

What is High Density Polyethylene?

HDPE (known as high-density polyethylene) is a type of thermoplastic that is made of petroleum. This material is widely used in various industries. It has excellent tensile strength and resistance to heat. You can also recycle it easily. Further, HDPE is suitable for both indoor and outdoor products.

Uses of High Density Polyethylene or HDPE

What is HDPE plastic used for? You can use high-density polyethylene in many ways and in several sectors. For example: HDPE medical applications include medical packaging, disposable devices or laboratory ware. Below we list all other major HDPE applications.

1. HDPE Packaging

One of the most popular uses of HDPE is in the packaging industry. Companies use it to make strong and safe packaging or beverage containers. Because, this plastic is easy to process and protects materials well. It also allows you to recycle and reuse materials.

HDPE Plastic Bags: With this material, you can make strong and durable bags. You can produce them in large quantities in less budget.

Food & Chemical Containers: HDPE plastic is widely used in the food and chemical container industry because it resists chemicals and contamination. You will get safe containers to store liquids and solids.

HDPE Plastic Bottles: Due to its lightweight and resistant to damage properties, you can use this polymer to make bottles. You can use them for chemicals, cleaning liquids or other industrial fluids.

Is HDPEe safe for drinking water? You use HDPE to make water storage tanks, bottles and pipes. Because, it does not leach harmful chemicals into water.

2. HDPE Piping Systems

The piping industry prefers high density polyethylene because it is strong and flexible. Further, it can handle high pressure and resist chemicals or corrosion. Hence, the pipes made from this polymer last longer and need less maintenance.

Natural Gas Distribution: For gas pipelines, this petroleum plastic provides leak free joints through fusion welding. This type of system works well in cities and earthquake prone zones.

Water and Sewer Pipes: Industries use HDPE for safe water supply and sewage systems. Because it can handle corrosion and bacteria.

HDPE Irrigation Pipes: In agriculture sectors, you use HDPE for irrigation pipes due to its resistance to chemicals such as fertilizers.

3. Consumer Goods

This plastic is highly resistant to moisture and impact, which improves product life too. These properties make HDPE ideal for consumer goods. You will find it in household items, storage solutions or reusable products.

HDPE Furniture: You can make many furniture items with high density polyethylene. These include chairs, tables, benches, cabinets and storage furniture. And, it is also common in outdoor furniture.

Household Products: As it is safe for food containers, HDPE is used worldwide to manufacture everyday home items. You see it in home utility products, food storage containers, bins cutting boards.

HDPE Toys: In children’s toy factories, this plastic is used on a large scale. The reason is, it does not break easily & handles rough play.

4. Applications in Automotive Industry

Due to the strong and durable properties of HDPE, you can use it in various automotive sectors for different purposes. Below are some top uses of HDPE in your vehicles.

Vehicle Interior Parts: You can use HDPE for the manufacturing of vehicle interior parts. Because it is strong and easy for you to shape it. For instance: you can make your car door panels, dashboards or trim.

Car Bumpers & Protective Panels: The automotive sector uses HDPE in many parts such as bumpers, protective panels, liners and trims. It makes your vehicle parts lightweight and improves their lifespan too.

Vehicle Fuel Tanks: This plastic type is ideal for you to make fuel tanks. It stops corrosion, risk of cracks, leaks & chemical damage. Moreover, it allows you to design tanks which are lightweight and safer for vehicles.

5. Use in Construction

High density polyethylene is popular for construction materials because it resists chemicals and UV radiations. You will find it lightweight and easy to install. This way, you can save time and reduce labor costs.

Landfill Liners: Well, landfill liners are protective layers which you place at the bottom of landfills. You can roll or weld HDPE sheets to cover the landfill completely to prevent contamination.

Exterior Wall Panels: The plastic sheets made of high density polyethylene are commonly used to protect outdoor walls from moisture. With its use, you can make your building walls last longer with less maintenance.

Corrosion Resistant Pipes & Fittings: Mostly, you use pipes to carry water, sewage or chemicals made of HDPE. Its flexibility allows the pipes to handle pressure better.

6. HDPE For Agricultural Uses

The excellent properties of HDPE like durability, resistance to chemical, corrosion and harsh conditions make it perfect for farming items. It allows you to install long lasting irrigation systems with less maintenance costs.

Plant Shelter Sheets: The cover you use to protect your plants or crops from sunlight are made of HDPE. These sheets also block excessive moisture & chemicals.

Farm Water Storage: As this plastic is strong and does not allow leakage, you can use it to design storage tanks to store water & fertilizers.

Mulch/Soil Cover Films: Mulch films used to cover soil also contain HDPE. Because it is flexible, strong plus can manage sunlight too.

7. Telecommunication & Electrical Items

For these sectors, you require materials which provide excellent insulation and prevent signal interference. So, HDPE is your perfect choice. It is used in different ways.

Wire Protection: As it can block moisture, this plastic is used to insulate electric cables. Its flexibility allows you to bend and route wires easily around obstacles.

Fiber Optic Cable Sheathing: The sheets made of high density polyethylene are used to protect fiber optic cables. This way, it keeps wires safe and you will get reliable data transmission.

Cable Protective Pipes: You can use HDPE conduit pipes to shield underground cables from physical damage. Due to this petroleum plastic flexibility, you can maintain cable alignment over long distances.

8. Marine Usage of High Density Polyethylene

HDPE is also ideal for your marine applications because it does not absorb water. Furthermore, its low friction surface resists damage from waves and movement. Also, this material (HDPE) can stay in water or salty seawater and never get damaged & corroded over time. You can use it for docks, floating platforms, boat fenders, bumpers and fenders.

9. HDPE Road and Traffic Safety Products By JACKWIN

Road Cones: You can place HDPE made traffic cones on roads to guide traffic safely. They only bend without breaking when your vehicle hits them.

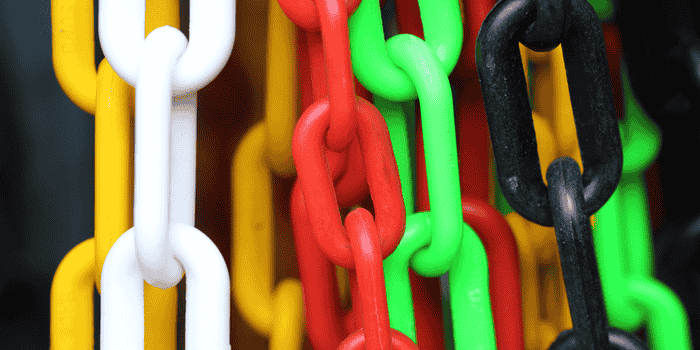

Plastic Chains: Jackwin manufactures strong and durable plastic chains. You will get them in different lengths and colors. Plus, you can use them to mark areas, control traffic or restrict access safely.

Warning Tapes: Designed with high density polyethylene, warning tape is lightweight and strong. You should use this tape to alert people about hazards.

Barricade Tape: HDPE is used to make barricade tapes that can handle tough outdoor conditions. You can use it to block off construction sites or dangerous areas.

Plastic Orange or Warning Mesh: Our warning mesh is made of 100% virgin HDPE material. It has a bright color like an orange mesh. You can use it to mark underground pipes, ducts, cables and service lines in highways.

Delineator Post: You can install delineator posts easily and they require no maintenance. Their bright colors make them highly visible to you.

Parking Bollards: JACKWIN parking bollards are strong and durable. You can install them in your parking lots or pathways.

Traffic Panels: HDPE traffic panels are lightweight, so easy to install. You can place these panels to display road information or warnings.

Trench Covers: Our trench covers designed with high density polyethylene are ideal for your low budget project. They are durable and have a slip-resistant surface.

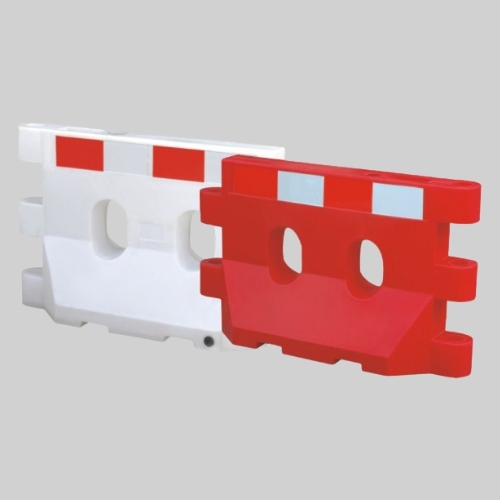

Plastic Water Filled Barriers: Made from bright HDPE material, water filled barriers are strong and easy to move. You can install these barriers for traffic control or temporary work zones.

Traffic Drum: Traffic drums are placed to guide traffic or mark construction zones. These drums have bright colors and are durable on roads.

HDPE vs PE

HDPE (high-density polyethylene) is basically a type of PE (polyethylene) that is strong and hard. You can use it for heavy-duty items such as pipes and containers. On the other hand, you will find regular PE (LDPE or LLDP) soft and more flexible. That’s why you should use it for bags, films, or other lightweight products.

Answers To Your Important Questions

How is HDPE Plastic Made?

HDPE is manufactured by heating petroleum under controlled conditions. This process is called cracking. The gas molecules join together to form long chains called polymers, which turn into polyethylene.

Is HDPE Food Safe?

Yes, HDPE is food safe when you manufacture it according to standards. So, you can use it for containers and bottles. Moreover, it does not react with food or liquids and is widely approved for food contact by safety authorities.

Why is HDPE Used For Milk Bottles?

High density polyethylene is widely used for milk bottles because it is strong and affordable. Also, it can resist chemicals, protect milk during transport & never react with dairy. Its recyclability also makes it safe.

Is HDPE Toxic When Heated?

No, food grade HDPE is generally harm free when you heat it for normal use. This means, you can use it with boiling water. However, if you overheate it, HDPE can release harmful fumes.

Can You Paint Polyethylene Plastic?

Yes, you can paint polyethylene plastic, but it can be tricky for you. Because, this plastic has a smooth and non porous surface. To make paint stick, you need to clean the surface well. You must use a primer designed for plastics before paint.

Is High Density Polyethylene Recyclable?

Yes, HDPE is fully recyclable. Hence, you can collect and process it to make new products such as bottles, containers, pipes and plastic lumber. In this way, it reduces waste and supports a more sustainable environment.

Final Note

JACKWIN is a professional manufacturer of polyethylene and HDPE safety products. For manufacturing these items, our R&D engineers follow all safety standards to meet quality and regulations. We have a big stock of HDPE road and traffic safety products in our factory. You can contact us for a quick quote and get discounts on bulk orders.

-80x69.png)