In-house Manufacturing Capacities

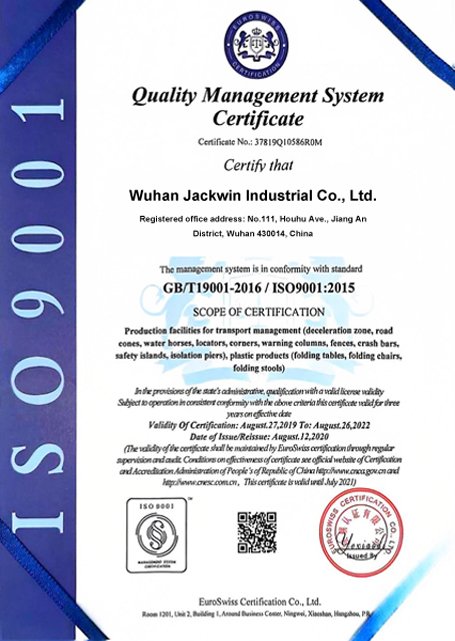

JACKWIN is a road safety product factory audited by ISO9001 and ISO14001 quality control systems. We manufacture plastic and metal A-frame barriers and barricades by injection, blow and extrusion molding processes. Metal barriers and stands are made of galvanized steel through the welding process.

Manufacturing Facilities and Product Features:

- Factory areas over 5000 square meters.

- Five production lines – blow/injection/rotation mold machines, metal fabrication machines.

- Made of high-density polyethylene material, impact-resistant, and fade-resistant.

- Stackable legs are easy to transport and store.

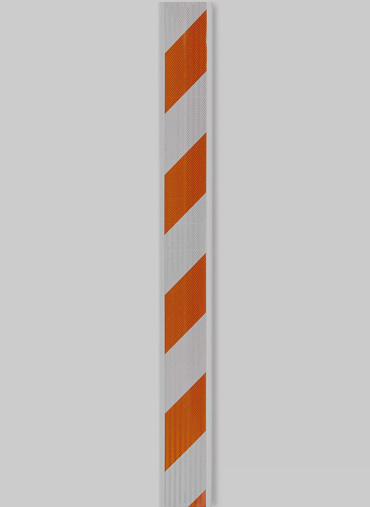

- Lightweight I-Beams are reflective and highly visible.

- Composition

- Applications

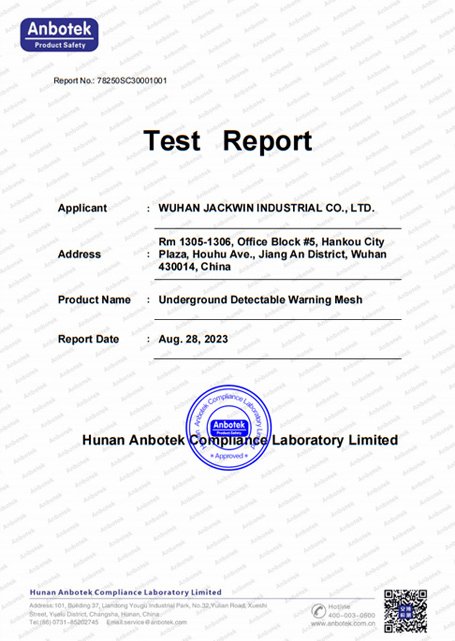

- Certificates

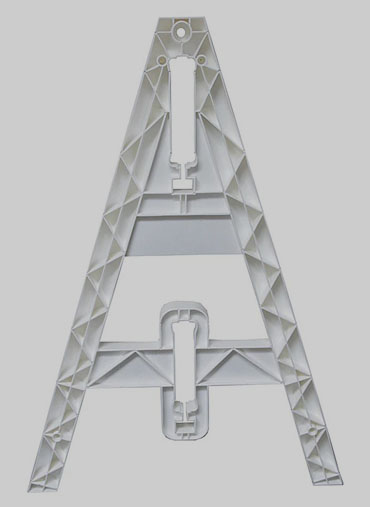

JACKWIN A-frame barricades are composed of legs, an I-beam, reflective sheeting, and a barricade light, all of which come together to form a barricade system used for traffic control and construction sites. Barricade legs are made of PVC material by the injection molding process, and I-beams are made of ABS by the extrusion process. Browse the following images to get a better understanding of JACKWIN A-frame barricades.

According to MUTCD standards, OSHA, and DOT compliance, A-frame barricades are widely used as safety and traffic control tools across various fields in the United States market. Browse the following key applications, and if you have any questions or inquiries, please feel free to contact us now!

- Construction Site Safety

JACKWIN A-frame barricades are used for hazard demarcation and equipment in construction sites and workplaces to isolate machines and prevent safety for workers: for example, excavation zones, dig trenches, and wet concrete areas.

- Crowd Control & Event

As you can see, A-frame barriers are placed on festivals, concerts, VIP sections, restricted areas, and entry queues, ideal for creating a pedestrian pathway.

- Traffic and Road Management

JACKWIN A-frame barriers are temporarily used for road closures when utility works, maintenance, or accidents.

Certificates

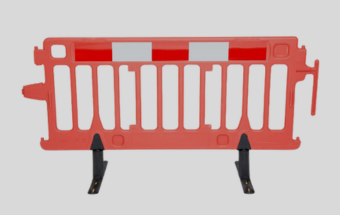

Plastic A-frame Barricade

JACKWIN’s plastic A-frame barricade is a great solution to prevent unauthorized access to parking areas, roadwork zones, event venues and restricted areas. Designed with durable A-frame legs, our barricade is convenient to set up and assemble/disassemble. Filled with water or sand, JACKWIN barricades are stable in high-traffic or crowded areas.

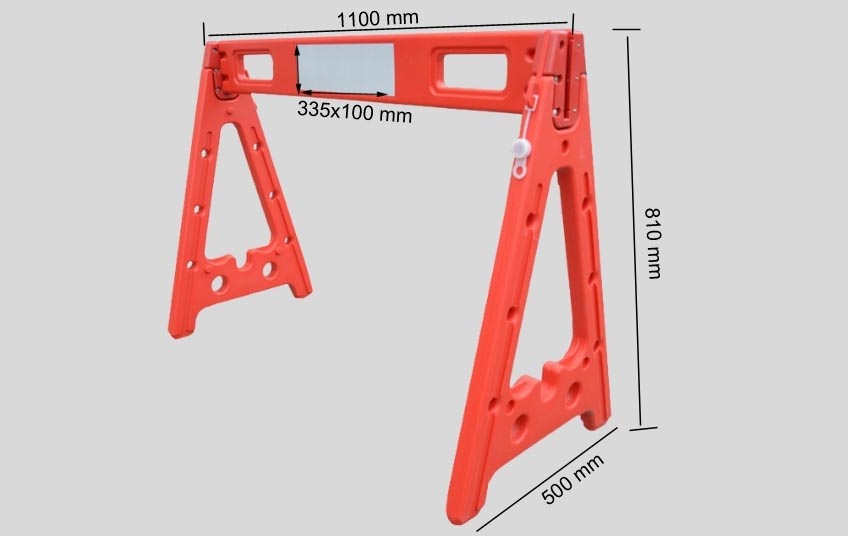

Type 1 Barricade

JACKWIN Type 1 barricade, also named type I barricade, according to the United States MUTCD standard, type 1 barricade is an A-frame foldable barrier with 1 reflective rail. It is designed for guarding pedestrians and directing street traffic, reducing the impact of traffic, and preventing accidents.

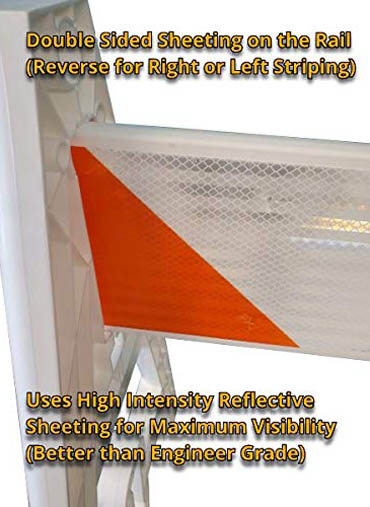

The I-beam is at least 24 inches long and has orange and white reflective strip sheeting. Sometimes, the second rail is blank without reflective sheeting, which helps to support a good stand.

Type 2 Barricades

JACKWIN Type 2 barricade, also known as type II barricade, like type 1, type 2 barricade is also lightweight, foldable, and has two rails, but both rails are covered with reflective orange and white strip sheetings. When hit, they will also fold and collapse.

The difference from type 1 is that they have different uses. Type 2 barricade is used on highways and dangerous construction sites.

Type 3 Barricades

The difference between Type 3 barricade (type III) and type I and II offered by JACKWIN can not be folded due to fixed support. It is typically made of welded galvanized steel, and the board can be constructed from wood or plastic. It is larger and longer in size, with a length of at least 4 feet, and is mainly used for road closure due to its larger size and high visibility.

3 pieces of reflective HIP orange and white stripe panels, equipped with a 360-degree barricade flashing light.

-80x69.png)