When it comes to purchasing traffic regulatory equipment, choosing the right material is very crucial, as it not only ensures road users’ safety but also lasts longer and is cost-effective. One of the most commonly used materials for traffic control devices is reflective sheeting.

In this guide, you’ll learn about the reflective sheeting standards established by ASTM, related to its visibility and performance. The aim is to make you aware of retroreflective standards so you can make correct choices and stay compliant with MUTCD and FHWA compliance.

What Does ASTM Stand For?

ASTM actually stands for ASTM International, but previously it stood for and was an acronym of “American Society for Testing and Materials”, which is a non-profit, globally-known, and recognized organization for developing and publishing standards for materials, products, or services.

What are ASTM Codes Standards?

ASTM Code Standards are a set of internationally made up and recognized standards. Generally, these standards are made through a voluntary consensus process, by including industry experts, manufacturers, government agencies, and academics in a committee within ASTM International. These code standards cover everything from construction materials, consumer products, and industrial equipment to safety procedures.

What is the Purpose of ASTM Standards?

ASTM standards aim to establish standards that aid manufacturers in improving the overall quality of a material and product, safety, and performance. In standards, they specify the development guidelines and testing methods for products, materials, and services, which have a track record in reducing the risk of failures and accidents.

It’s important to note that ASTM International doesn’t itself enforce its developed standards for products. However, other regulations and compliance bodies (like MUTCD) adopted these standards and even made them compulsory to follow.

What is ASTM D4956?

ASTM D-4956 is a consensus-based standard for reflective sheeting material, which is developed and published by ASTM International. This standard specifies regulations and testing methods to improve sheeting reflective property, color coding, visibility, durability, and reflectivity requirements. Also, specifies retroreflective sheeting classification across its types and classes.

What is ASTM D4956-19?

ASTM D4956-19 is the revised version (2019 edition) of the earlier reflective sheeting standard (D4956-13), covering the same flexible glass-bead and microprismatic sheeting (Types I–XI, Classes 1–5 as the previous 2013 revision, along with some new specifications.

ASTM D4956 04 vs ASTM D4956 09 vs ASTM D4956 13

- ASTM D4956‑04 is the earliest reflective sheeting standard that was published back in 2004. This had actually covered beaded and prismatic retroreflective sheeting types (I-X) and classes (1-5) approved in the original version of 1989.

- ASTM D4956‑09 (2009 edition) is the revised version of ASTM D4956-04 with some minor updates added, such as clarifications and improvements in testing procedure.

- ASTM D4956‑13 (2013 edition) is the revised version of D4956-09 with the same continuation of types and classes as earlier editions (D4956‑09) but with likely enhanced specifications.

ASTM D4956 Role in Traffic Safety

ASTM D4956 plays a significant role in keeping U.S. roads safe. It sets clear standards for the reflective sheeting that is used on traffic sign-making.

Now, consider if there were no standards made for reflective sheeting, or if they aren’t followed, facilities may purchase traffic regulations devices made up with any material. As a result, their brightness may fade early, which could lead to confusion and even accidents.

Without these guidelines, there would be no benchmark for material properties, which means road safety would be left to chance. This clearly explains the importance of the D4956 standard.

Types of Reflective Sheeting Under ASTM D4956

ASTM D4956 04 covers beaded and prismatic reflective sheeting, explaining 1-XI types based on their construction, brightness level, durability, and intended use. They are further divided into two main categories: Beaded Sheeting and Prismatic Sheeting. Now, let’s discuss each type:

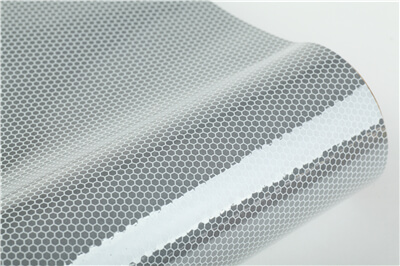

Beaded Reflective Sheeting

Beaded reflective sheeting has a tiny glass-bead enclosed lens. So, when a light falls on the equipment made up with this sheeting, it reflects light back toward its source. It’s commonly used for general-purpose signs that don’t require high brightness.

-

Type I – Engineering Grade

ASTM D4956 Type 1 is the most commonly used type with medium-intensity reflectivity. It’s ideal for non-critical signs that are used at places where visibility is not a problem. Common applications of this glass-bead sheeting include parking, construction zone devices, delineators, or temporary signs.

-

Type II – Super Engineer Grade

Type II has higher reflectivity than Type I, that’s why it is ideal for those safety devices that are used at places where better visibility is needed. Common applications of this bead-based sheeting include urban road signs, construction zone devices, and highway signing.

-

Type III – High-Intensity Beaded Sheeting

This type, on the other hand, is more reflective and more durable. It’s ideal for use in regulatory, warning, and guide signs-making. Since it’s bead-based and has high reflectivity, it best suits higher-speed roads compared to Types I and II.

Prismatic Reflective Sheeting

Where beaded sheeting uses glass-based, prismatic sheeting uses microprismatic technology, these are brighter, more durable, and perform better in low-light and long-distance viewing conditions, compared to beaded sheets.

-

Type IV – High-Intensity Prismatic (HIP)

ASTM Type III & IV reflective sheeting both have high-reflective properties, but Type III uses glass-beaded technology, while Type IV uses microprismatic technology with an unmetallized microprismatic element. Type IV sheeting is ideal for making regulatory and construction zone signs. It’s more visible at night and from wider angles than beaded sheeting.

-

Type V – Super-High Intensity Prismatic

This type has an even super level of brighter visibility with a metallized microprismatic element. Type V is often used in emergency and safety equipment, such as barricades, roll-up signs, delineators, and traffic cones. This material is flexible and can be used on various surfaces.

-

Type VI – Roll-Up or Flexible Sheeting

This sheeting is also high-intensity reflective, but is more flexible and often made up of vinyl microprismatic material. Type VI is typically used for temporary and lightweight signage, such as traffic cone collars, post bands, and portable signs used in construction or work zones.

-

Type VIII – Long-Distance Visibility Sheeting

This sheeting is used for signage that is used in areas where long-range visibility is critical, such as high-speed roads and large guide signs. Devices made up of this sheeting provide better brightness than Type IV and are engineered to perform well from greater distances and angles.

Note: As per the ASTM D4956-19, previously retroreflective sheeting classified as Type VII has been discontinued and now re-classified as Type VIII!

-

Types IX – Very High-Performance Prismatic Sheeting

Type IX has a very high intensity retroreflectivity property. Equipment made with this sheeting is highly visible at short-to-medium road distances. They also work great for overhead and shoulder-mounted signs.

Note: As per the ASTM D4956-19, retroreflective sheeting designated as Type X has been discontinued and now re-classified as Type VIII!

-

Type XI – Highest Reflectivity Available

ASTM D4956 Type XI is the most advanced reflective sheeting type, introduced in ASTM reflective sheeting (D4956-19 version), and used for complex environments signage, such as urban intersections, sharp curves, construction sites, or work zones with high-speed traffic. This sheeting provides maximum visibility from wide angles and long distances.

ASTM Standard Classes of Reflective Sheeting

ASTM D4956 standard has classified reflective sheeting types (from I to XI) into five classes to further explain their application style, adhesive type, and performance level.

-

Class 1 – Adhesive Backed (Pressure-Sensitive)

Class 1 sheeting comes with a pressure-sensitive adhesive. You just need to peel it off and then stick it directly onto a clean surface. It’s quick to apply and typically can be applied on aluminum or metal sign panels. Most permanent road signs use Class 1 materials, as they have long-lasting performance.

-

Class 2 – Heat-Activated Adhesive

This class, on the other hand, requires heat and pressure for adhesive activation. This sheeting needs to be installed by applying heat at 150°F and pushing the material so that it secures a permanent bond to the surface. Class 2 is ideal for factory-level applications and can withstand extreme weather conditions.

-

Class 3 – Removable Adhesive

As the name explains, Class 3 reflective sheeting uses a removable adhesive. It sticks well but can be taken off without leaving residue. Perfect for work zones, detours, or short-term traffic control signs that need to be moved or replaced often.

-

Class 4 – Adhesive Backed (Pressure-Sensitive)

This type of sheeting is adhesive-backed and shall be applied to the surface at a low temperature and under pressure. The ideal temperature to apply this sheet should be +20°F without applying any solvent, adhesive, or heat.

-

Class 5 – Fabric Backed for Flexible Use

Class 5 sheeting is flexible, non-adhesive, and fabric-backed. This sheeting is used for self-supporting traffic products such as roll-up signs, cones, or barricades. It provides good reflectivity while allowing for repeated folding or flexing without cracking.

ASTM Reflective Sheeting Standards

-

Performance Criteria & Test Methods

Retroreflectivity (RA Values, Candela Metrics)

ASTM measures how much light returns to a driver’s eyes using the coefficient of retroreflection (Rₐ). Different sheeting types (I–XI) have minimum Rₐ values at specific geometry setups.

ASTM specifies that manufacturers measure reflectivity at 0.2° observation with −4° or +30° entrance angles. These requirements ensure each type of sheeting stays visible enough under headlights and from different vantage points.

Observation / Entrance Angles

The observation angle is basically the angle between the light source and the driver’s eye (commonly 0.2°, 0.5°, or 1.0°). Whereas, the entrance angle is the angle between the light source and the sheeting surface (typically −4° or +30°).

ASTM also mandates checking performance with testing angles at combinations of these angles. Doing so lets you simulate real-world scenarios, like tight corners, high-mounted signs, or unconventional light reflections.

Colorimetric & Gloss Standards

The daytime appearance of signs is controlled using CIE chromaticity coordinates and luminance factors. ASTM reflective sheeting standard specifies testing for colorimetric and glass standard using any of the outdoor weather specimens.

Durability: Weathering and Abrasion Test

ASTM tests include:

- Outdoor weathering: This says that reflective sheeting should be weather resistant and should not show cracking, scaling, or pitting. Also, sheets must retain a percentage (50–80%) of the original Rₐ after exposure.

- Accelerated weathering: In this, the reflective sheeting’s outdoor weathering performance is tested in a laboratory, before the sheet is available for use. Reflective sheeting passes through lab-based UV, heat, and moisture cycles that replicate years of exposure to test its performance.

- Abrasion/resistance tests: Here, impact tests are made on the sheeting by dropping a weight onto the sheeting; there must be no cracking or delamination outside the impact zone.

ASTM Safety Standards

ASTM’s safety standards cover several guidelines for workplace and consumer safety. This includes wearing protective clothing, footwear, and gear in the workplace, ergonomics, and ventilation systems.

The standard also includes ga uide for materials selection, based on test methods to identify, evaluate, and control hazards, in the workplace. These standards clearly mandate the proper handling, transport, storage, and design of protective equipment so that everyone stays safe.

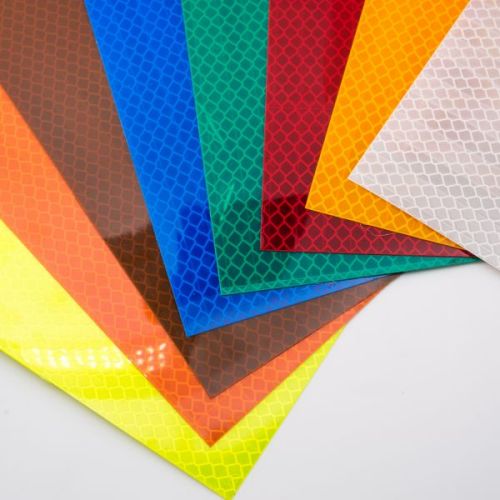

ASTM Color Standards

ASTM’s standard also defines exact color specifications and tolerances for high-visibility signage in daytime and nighttime conditions. For reflective sheeting, the ASTM D 4956 standard mandates that white, orange, yellow, green, red, blue, and brown colors’ reflective sheeting should be used for signage.

However, it is important to note that the “luminance factor” of these colors may vary depending on the chosen sheeting type and class.

ASTM Reflective Sheeting Purchasing Standards

ASTM D4956 standards have provided essential ordering criteria for manufacturers and contractors. So, when buying reflective sheeting materials, always mention:

- ASTM Designation Number (Latest one)

- Reflective Sheeting type (I–XI)

- Adhesive Class

- Daytime Color

- Length and Width of Reflective Sheets

- Intended Use or Application

- Weather Durability

- Environment Condition

And mention any additional information, if you have any. This helps you choose the exact reflective sheeting material best suited for your project needs.

MUTCD and FHWA Compliance and Standards

The Manual on Uniform Traffic Control Devices (MUTCD) and the Federal Highway Administration (FHWA) play a major role in standardizing and mandating traffic signs across the U.S. roads.

When it comes to reflective sheeting, both MUTCD and FHWA require facilities to use road signage and traffic regulation devices made up of retroreflective sheeting material that must follow the ASTM D4956 types and classes.

Following the ASTM reflective sheeting specification while manufacturing signage is crucial to get signage approved by the FHWA to be considered compliant. If a sign doesn’t meet these guidelines, this means clear violations and rejected projects.

Why is Choosing the Right Manufacturer Important for Road Signs?

Reliable manufacturers and suppliers provide high-quality and durable road signs made up of different types of reflective sheeting material for U.S. road conditions. They also provide products at factory wholesale prices and even offer custom-made solutions for your brand.

Conclusion: JACKWIN’s Role as Reflective Sheeting Manufacturer

Jackwin has been the leading reflective sheeting manufacturer in China since 2008. At Jackwin, we manufacture commercial-grade, engineering-grade, and ASTM D4956, D8514 & EN 12899-1(RA1, RA2) compliant traffic regulation equipment with different types of reflective sheeting.

Our reflective sheeting products include traffic signs, traffic cones, high-visibility clothing, traffic drums and barrels, delineators, and road barriers. JACKWIN also offers customization solutions to brands and provides you with the products as per your colors, sizes, patterns, and materials selection, all at factory wholesale prices.

Contact us today to send your inquiry!

-80x69.png)