Cable Protection Tiles for sale

JACKWIN is a leading manufacturer and supplier of cable protection tiles in China with 18 years of experience. We can provide cable protection solutions to you with underground warning tapes, cable protection tiles, underground cable covers, and underground warning meshes.

What are JACKWIN Cable Protection Tiles?

JACKWIN Cable protection tiles are primarily plate-shaped cover materials to protect cables, gas pipelines, buried electrical mains, fiber optic cables, water pipes, and similar infrastructure. Our cable tiles are suitable for LV, MV, HV, and EHV cables, including 11kV, 33kV, 66kV, 132kV, and up to 400kV.

Functions of our cable cover tiles:

- Protective Warning Function.

- Distinguishes between different types of facilities to prevent construction errors.

- Permanent marking with a maximum service life exceeding 20 years.

- Extends cable operational lifespan with resistance to pressure, corrosion, and damage.

If the above functions can assist your projects, you can click to send an inquiry.

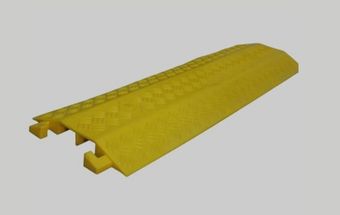

Cable Protection Covers by shape

JACKWIN offers contractors and distributors the most comprehensive shape classification of cable covers. If you are interested in our products, please send an inquiry.

Made of HDPE/concrete, used for protecting high-voltage cables and substations, 10-25mm thickness. high-strength compression resistance.

2-12mm thickness and 15-70cm width customized, high impact resistance and high tensile strength, composed of HDPE / Recycled PE / PVC with high-density or low-density raw materials.

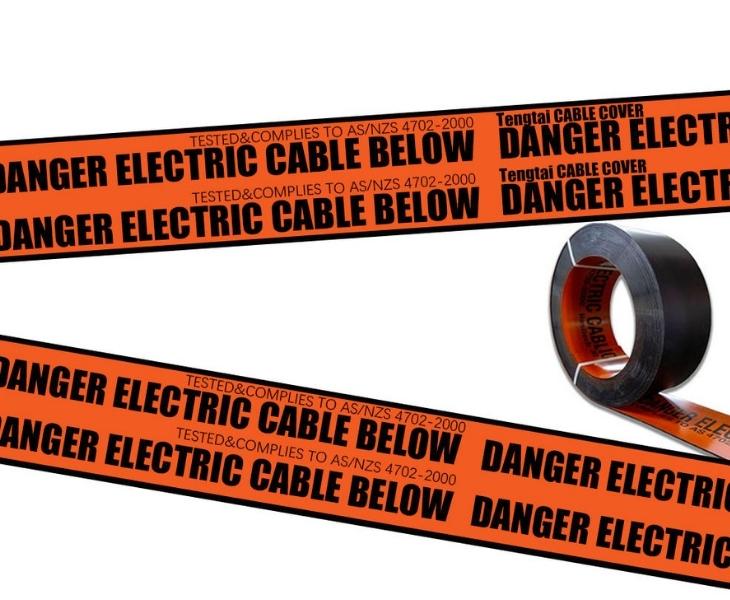

Non/detectable underground warning tape, made of HDPE material and stainless steel wire or aluminum laminated, customizable in colors and markings.

Made of 100% virgin HDPE material incorporating traceable stainless steel wire, continuous roll-out installation, customizable length, width, and thickness.

Made of PVC material, specially formulated plastic slabs, 2-6mm thickness, equipped with an ultimate interlocking linkage system.

Cable Protection Covers by Material

JACKWIN offers contractors and distributors the most comprehensive range of cable covers with material classification. Below you can find detailed specifications for these different types.

-

Polymeric Cable Cover

Polymeric Cable CoverComposed of recycled polyethylene, extremely flexible and adaptable, cable warning and protection.

-

PVC Cable Tiles

PVC Cable TilesEco-friendly and Recyclable, high wear resistance, longitudinal rigidity, lateral connection.

-

-

-

Concrete Cable Tiles

Concrete Cable TilesPrimarily used for LV and HV cable protection and identification, compliant with BS 2484 specifications.

Features for Cabile Protection Tiles & Covers

JACKWIN cable covers offer an extensive array of features and functions. Below is a detailed description.

Suitable for LV/MV/HV cables, water pipes, gas lines, and communication facilities.

Capable of withstanding pressures ranging from 1500 to 5000 N or even higher.

Prevents water erosion and acid component corrosion in the soil.

Adaptable to rainy, snowy, and low-temperature weather, or to conditions of heavy acid rain.

Manually stacked over pipes and connected using interlocking tabs.

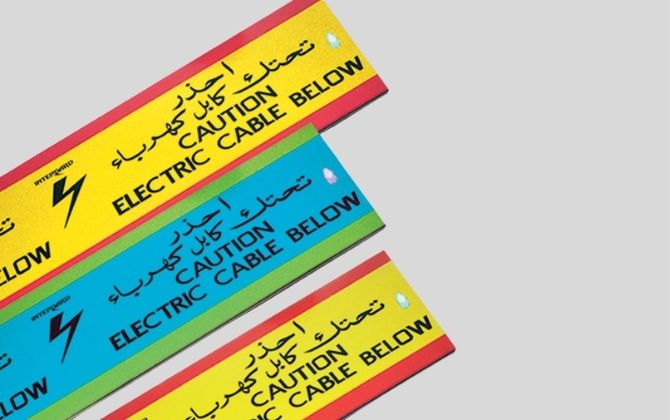

High-contrast colors and conspicuous markings, effectively reduce accidental digging.

A minimum shelf life of 30 years while maintaining its protective and warning function.

What Can We offer?

- We offer cable trench tiles in various models, colors, applications, and raw materials(PVC/PE/concrete) for your choice.

- We offer a robust global supply chain capable of meeting all cable tile procurement, resale needs, project a one-stop solution.

- JACKWIN can reduce your overall costs while delivering premium underground cable tiles.

If you’d like to learn more about our cable protection tiles, click here to send your inquiry.

Advantages of PVC|PE Cable Tiles

PVC Cable tiles are composed of thermoplastic polymers, offering a degree of flexibility while also providing impact resistance. PVC is one of the most reliable polymers for all your manufacturing needs.

- UV-resistant material can be added.

- Recyclable plastics can promote environmental protection.

- Materials possess a certain degree of ductility and flexibility and can withstand impact and heavy loads.

PE cable tiles are primarily composed of rigid thermoplastic materials, offering rigidity and durability suitable for moderate temperatures.

- Wear-resistant and impact-resistant

- Easy to cut into various shapes, reducing installation time.

- Provides perfect electrical isolation and serves as a versatile insulator with a wide range of applications.

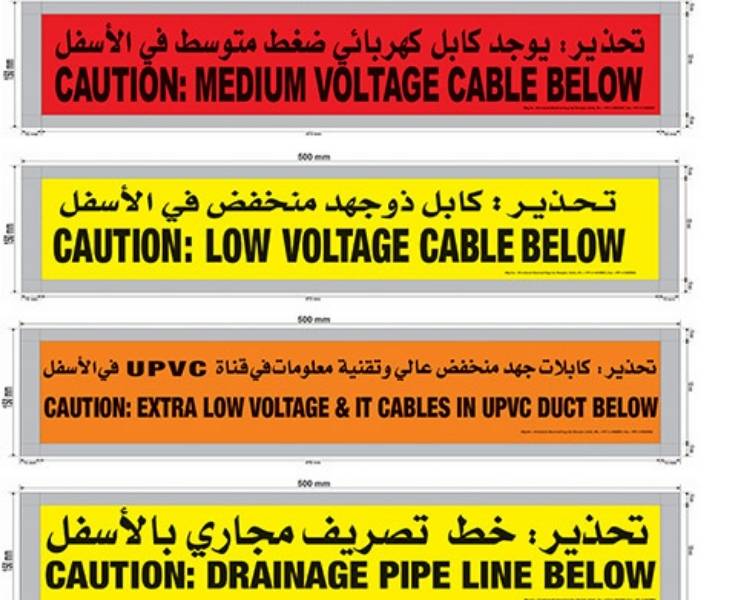

Cable Protection Tile Colors

You can select JACKWIN cable covers with different markings to suit engineering applications, as follows:

- Red: “DANGER – HIGH VOLTAGE CABLE BELOW”, used for HV cable protection.

- Yellow: “WARNING – GAS PIPELINE BELOW”, used for gas pipeline protection.

- Orange: “CAUTION – FIBRE OPTIC CABLE BELOW”, used for fibre optic protection.

- Blue: “WATER MAIN BELOW”, used for water main protection.

- Purple: “RECLAIMED WATER BELOW”, used for reclaimed water pipe protection.

- Green: “SEWER LINE BELOW”, used for sewer line protection.

- Black: “LOW VOLTAGE ELECTRIC CABLE BELOW”, used for low voltage electric cable protection.

If you require custom color labels, please click here to send an inquiry.

Cable Protection System

JACKWIN Cable protection system can ensure the durability, load-bearing capacity, corrosion resistance, and waterproofing of the materials. Through seamless connections, we reduce maintenance costs and time for your projects.

Our cable protection system is primarily divided into the following components:

- Cable conduit system. Cable protection sleeve is primarily composed of polyurethane, providing exceptional abrasion resistance and impact resistance to withstand harsh weather conditions.

- Cable protection covers. JACKWIN cable tiles are primarily composed of PE/PVC/concrete and serve as waterproof protective plates buried underground and placed above cables. You can use it as a second layer of protection for the cable.

- Underground warning tape. You can use our tapes as a warning barrier for cable protection. Although plastic film is thinner and more fragile than plastic sheets, making it more prone to damage, it offers a higher cost-performance ratio. You can also choose detectable tapes with either steel wire or aluminum foil to provide a metal detection signal.

Cable Protection Tiles Installation

Construction Process:

- After laying cables or other pipes, you must cover them with 100–150 mm of fine sandy soil and ensure the base beneath the tiles is level.

- You can choose to lay cable protection covers manually or roll them by machine, then connect them using clips or grooves.

- Backfill the ground to its original condition using carefully selected soil layers, with each layer below 300mm in thickness.

Construction Precautions:

- Ensure cable tiles are free from deformation and exhibit consistent color, shape, and thickness.

- Ensure that the backfill sand contains no hard objects such as stones or bricks. Do not use machinery to compact directly on the protective plate.

- Ensure cable tiles are positioned directly above the cables, with text facing upward and maintaining continuity.

Customized Cable Protection Tiles

JACKWIN supplies customization for any width, length, and thickness of cable protection tiles. Whether you’re a project procurement manager or a retailer, JACKWIN can provide the perfect cable tile customization solution.

Standard size: 2-10mm thickness, 15-70cm width.

Customizable size: we can cut to your specific requirements.

We have various markings and colors for your choice, and we can also customize as per your design.

Cable Protection Covers

JACKWIN cable protection covers are made of PVC material laminated with printed film. It’s designed for protection of 11 kV cable under MV-HV cable trenches or cable ducts and also widely used for underground buried unilities covering with gas mains, electricity, telecoms cables and water pipes.

Comparing to traditional cable warning tapes and meshes, JACKWIN cable protection tile are visible tensile resistance and strength against potential hazards caused by excavators in construction.

JACKWIN 11kV 33kV high voltage cable protection tile sized in 150(width)mm * 50(length) meters * 2(thickness) mm or customization.

Resources

Know more products specification? Just View and Download JACKWIN catalogue by clicking link.

Know more about JACKWIN products and company? Just click video link, you can get more than you think.

To learn more about JACKWIN products, please follow our knowledge center.

PE Cable Tiles vs Concrete Cable Tiles

PE Cable Tiles

Advantages:

- PE cable tiles are primarily suitable for low-voltage and medium-voltage cables.

- Adding UV stabilizers to raw materials during production enhances UV resistance.

- 100% recyclable

- Low production cost

- Excellent corrosion resistance, non-absorbent.

Disadvantages:

- Unable to withstand extreme pressure

- Limited high-temperature tolerance

Concrete Cable Tiles

Advantages:

- High compressive strength, capable of withstanding 5000N pressure.

- Suitable for protecting high-voltage cables.

- Resistant to water corrosion.

- Each panel weighs several dozen kilograms and remains stable without displacement.

Disadvantages:

- Heavyweight makes installation difficult.

- Relatively high production costs.

- Excessive rigidity but low compressive strength. Prone to deformation under horizontal pressure, susceptible to thermal expansion and contraction, and prone to cracking when encountering ground subsidence.

The two different materials of cable tiles produced by JACKWIN can be applied to different scenarios. You may select based on your needs. For further product specifications, please click to inquire.

Underground Warning Tapes vs Cable Protection Tiles

Underground Warning Tapes

Advantages:

- Extremely low material and installation costs

- Simple installation process, requiring only a quick roll-out.

- Used in combination with other covers to enhance warning effectiveness.

Disadvantages:

- Limited suitability for medium/high-voltage environments.

- Short service life, typically 5-10 years.

- Weak protective capabilities and no physical isolation functionality.

Cable Protection Tiles

Advantages:

- Service life exceeding 30 years

- Exceptional physical compression resistance and waterproofing/corrosion protection

- Wide applicability across low-voltage, medium-voltage, and high-voltage cables

- Reusable and recyclable

Disadvantages:

- Slow installation speed, requiring piece-by-piece laying

- High material and labor costs

- Rigid material with poor flexibility

JACKWIN Cable Protection Tiles for Application

JACKWIN cable warning tiles are widely used in urban infrastructure, railway/metro systems, airport/port infrastructure, industrial and mining areas, and renewable energy farms. Our tiles perform functions including warning and protecting from ground construction and high voltage.

JACKWIN cable tiles can be used to prevent damage to urban underground pipelines, including cables, communication backbone fiber optic cables, and control lines.

You can use our tiles to protect power and signal cables for railways and subway lines, ensuring the project progresses smoothly.

You can choose JACKWIN cable tiles to protect airport taxiways, apron lighting, and port container yard cables.

Our cable tiles are primarily used to prevent damage from heavy machinery, such as forklifts and loaders.

You can use cable tiles to protect cables in integrated wind-solar-storage energy projects, ensuring for not unaffected by seawater, humid environments, or high temperatures.

Our Manufacturing Workshop

JACKWIN’s factory production workshop covers an area of 1,000 square meters and houses a design team of 20 members. We process plastic pellets into PE sheets through extrusion and melting. You can see the specific process below.

This is our extruder machine. We place plastic pellets into the extruder, where they are melted at high temperatures and formed into continuous sheets.

These are our calender rollers. We flatten the molten sheet and stretch it to the specified thickness.

This is a cutting saw. We use this semi-automatic equipment to cut and shape panels to specified dimensions, ensuring consistency across product models.

This is a stamping machine. We place the plastic sheet onto the positioned protective plate, then transfer the ink layer onto the plastic sheet using a heated die head and pressure.

Our cable tiles are priced based on order quantity and real-time shipping costs. For specific details, please send an email inquiry.

- When installing cables, pay attention to the trench depth and select an appropriate underground location to prevent groundwater infiltration.

- Use PVC, PE, or cement cable tiles to protect cables from damage.

- Install warning meshes or warning tapes above the cables to prevent accidental digging.

- Use caution tape or warning signs above the work area.

The manufacturing process consists of five steps: extrusion, melting, cooling, cutting, and heat stamping.

-80x69.png)