Construction Barriers for Sale

JACKWIN offers a range of construction barriers, including acoustic barriers, construction dust barriers, pedestrian barriers, and water-filled barriers. Moreover, due to varying material requirements, you can choose construction barriers made from plastic, cement, metal( galvanized steel, aluminum, and stainless steel), fiberglass, and other materials. Our products strictly comply with construction barrier standards, organized by OSHA, MUTCD, and NCHRP.

If you are a construction company, government agency, municipal authority, public utility provider, event planning and security firm, industrial or warehousing enterprise, property management company, property owner, or safety equipment distributor, choosing JACKWIN is the cornerstone for advancing your business.

What are the Functions of JACKWIN Construction Barriers?

JACKWIN construction barriers are used to establish clear boundaries specifically for construction sites to prevent liability claims, primarily employed in road construction.

Depending on their intended use, they are categorized as permanent or temporary barriers.

- Construction barriers we produce are primarily used for safety protection at construction sites, significantly reducing your related financial expenditures.

- Local government strictly controls construction sites to protect the city’s appearance, prevent dust, and reduce noise. The construction process strictly complies with mandatory regulations, thereby avoiding the risk of fines and work stoppages.

- Construction barrier made of PVC and galvanized metal that features removable installation can significantly increase usage frequency, reduce costs, and enhance efficiency.

Types of Construction Barriers

JACKWIN construction barriers produced by our factory can meet the needs of various functions and are categorized into: construction noise barriers, construction dust barriers, construction pedestrian barriers, and traffic barriers for construction. Browse the following barriers and choose to send your inquiry now.

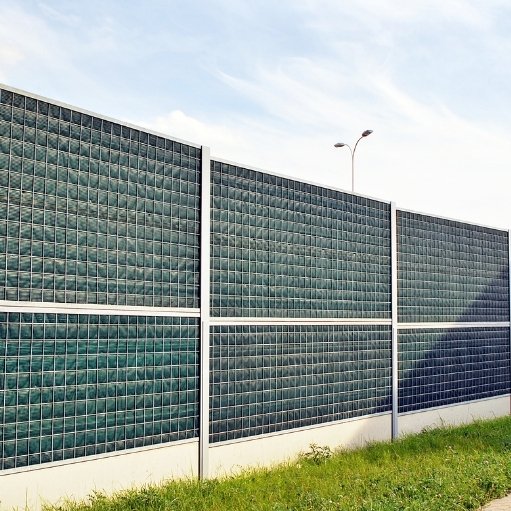

Noise levels can be reduced by over 27 dB(A). Soundproofing blankets, soundproofing panels, and soundproofing rollers are the main categories.

We offer dust-proof door kits, or individual dust-proof rod covers, dust-proof bags, zippers, and plastic sheeting. Materials: plastic sheet/ripstop sheet。

Temporary barriers, portable fences, and plastic road barriers.Available in metal or plastic materials.

Customizable to ensure compliance with or even exceed standards set by the Federal Highway Administration.

Construction Barriers by Materials

We offer various types of construction barriers: plastic construction barriers, metal construction barriers, water-filled construction barriers, and concrete construction barriers.

100% reusable, recyclable after damage. Manufactured using rotational molding or blow molding technology, with seamless construction. Add UV stabilizers to reduce aging, fading, and brittleness.

It can absorb and dissipate collision energy, reducing traffic accidents and casualties. Reusable, durable, and corrosion-resistant, minimizing cracking and breakage, reduces costs.

Service life exceeding 10 years, highest level of isolation protection, constructed from galvanized or carbon structural steel materials, with spray-coated/powder-coated surfaces for exceptional durability.

Highest-level collision protection, with steel reinforcement embedded in concrete, available in precast or cast-in-place configurations. It is a solution for high-speed, high-traffic road transportation.

JACKWIN Construction Barriers Features

Browse JACKWIN construction barriers and learn how to choose the right barriers.

Provide effective physical isolation, impact cushioning, theft prevention, and fall protection. Minimize property damage and personal injury to avoid compensation claims.

Made from materials such as galvanized steel or HDPE, offering resistance to corrosion, extreme temperatures, intense sunlight, and water exposure. Average loss per cycle is less than 0.1%, with nearly 100% reuse rate per product, significantly reducing maintenance and operating costs, and reducing procurement pressure.

The panels, base, and accessories can be easily disassembled and reassembled at any time, and can be flexibly arranged according to the terrain, size, and layout of the construction site.

Utilize recyclable materials, provide dustproofing and sound insulation, control runoff, promote environmental management and protection, and reduce environmental pollution.

Whether using H-beam base beams or water- or sand-fillable plastic bases, our barriers remain firmly anchored during high winds and severe weather, preventing overturn.

Utilize vivid colors such as orange, yellow, and black for warning purposes, while also employing high-intensity reflective panels to reflect vehicle headlights for enhanced visibility.

Construction Barrier Fence

Our construction barrier fences are primarily manufactured using stainless steel, galvanized steel, or PVC materials, providing you with safe, compliant, and efficient space management solutions.

JACKWIN construction barrier fence is your guarantee for accident safety on the job site. We offer unique advantages in construction safety, project time savings, and reduced depreciation costs for the following target end users:

- To the Project Manager: JACKWIN construction barrier fence is your guarantee for accident safety on the job site.

- To the company’s purchasing manager: Our barriers offer exceptional price advantages and volume discounts by selling globally with seamless logistics and maintaining ample inventory.

- To on-site safety officers: Our products comply with all environmental safety standards, feature robust construction, and are wind-resistant and tip-proof, making them a truly reliable protective solution.

Resources

Know more products specification? Just View and Download JACKWIN catalogue by clicking link.

Know more about JACKWIN products and company? Just click video link, you can get more than you think.

To learn more about JACKWIN products, please follow our knowledge center.

JACKWIN Construction Wall Barriers vs Construction Barrier Fences

Construction wall barriers and construction barrier fences JACKWIN produced are both tools for achieving construction isolation, but their materials and structures result in differences in their applications and functions.

Construction Wall Barriers: Primarily composed of solid metal plates or sandwich panels, concrete, and bricks, these structures possess exceptional physical stability, naturally achieving safety protection, visual screening, and noise control functions.

Construction Barrier Fence: Primarily composed of metal mesh, HDPE panels, and similar materials, these barriers rely on supporting structures and thus inherently possess lower physical strength, serving primarily as warnings and providing light obstruction. However, they offer relatively lower transportation costs, prices, and installation expenses.

Construction Barriers for Application

JACKWIN various types of construction barriers are widely used for many aspects. See the various applications below and see which category your project falls into!

JACKWIN road construction barriers are primarily used on highways, classified into Type 1, Type 2, and Type 3 based on the number of reflective strips. our products comply with MUTCD standards and offer high visibility.

Classified as either enclosed or open barriers, primarily used in construction site work areas. Metal barriers are the preferred choice for high-rise buildings in densely populated urban areas, while plastic barriers are used for lightweight engineering projects or temporary internal partitions.

Primarily used for runway and taxiway maintenance, terminal expansion and renovation, apron operations, and navigation facility protection. Airport environmental protection and public safety play a crucial role. Through features such as high reusability and rapid deployment, they can prevent accidents from causing massive property damage and various losses resulting from operational disruptions.

Primarily used for intercepting sediment and filtering permeate, these structures are vital facilities for preventing silt and debris clogging, thereby reducing the costs of post-treatment water purification and drainage system maintenance.

In-house Manufacturing

Our construction barriers are designed and manufactured in-house; the core advanced parts are imported. We have laser cutting, stamping, sheet metal processing, and powder coating workshops.

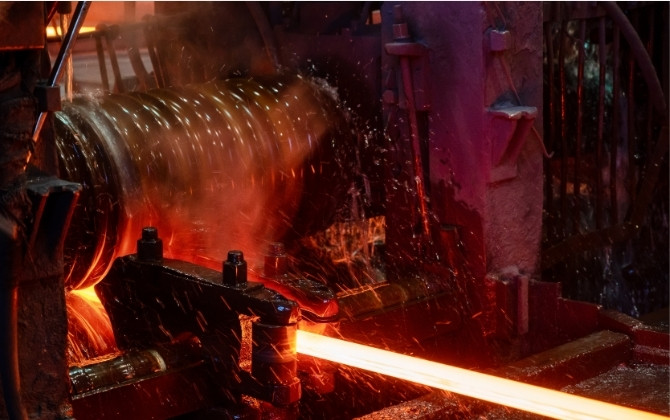

Our factory heats steel ingots or continuous cast slabs, then subjects them to rough rolling, finish rolling, and cooling to set their shape.

We uncoil the cooled steel coils, support them, and apply tension to avoid surface scratches and deformation. This step facilitates subsequent transportation.

We process steel coils into predetermined lengths and shapes through laser cutting, significantly enhancing flexibility and efficiency.

After the coiled steel strip is flattened, it undergoes roll forming to gradually bend into complex, constant-section open or closed profiles.

We have large CNC resistance welding machines that fuse each intersection point of the laid-out longitudinal and transverse wires using powerful electric currents.

We place the ground plastic powder into a rotating mold, heating it while it spins. Our products are formed under low pressure using gravity and rotational force.

Testimonials

It is an intelligent traffic management solution that integrates safety, efficiency, durability, and compliance.

you can choose construction barriers made from cement, galvanized silver, galvanized steel, fiberglass, and other materials.

We will ship your order as soon as possible.

-80x69.png)