Everything is encircled by stainless steel, from your room to your kitchenware, from basic railings to even traffic safety equipment. However, have you ever wondered how to produce it “without a stainless”? As opposed to other alloys, why does it not corrode? Furthermore, are all stainless steels made equal? We shall explain the magic of stainless steel in this guide from kitchen to traffic safety equipment, covering its components, its various types, and the elements that contribute to its (for the most part) resistance to rust. Let us tackle the alloy you use regularly with great trust.

What is Stainless Steel?

Iron is the primary component of stainless steel, which also contains at least 10.5% chromium. It is a sturdy and durable substance. It occasionally contains extra components in addition to other elements like nickel and molybdenum. The main component, chromium, covers the metal’s surface in a thin, imperceptible layer that protects it against damage and rust. It is less likely to get rust than regular metals, which is why it got the name “stains less.”

Here is a short overview of the essential components and their roles, since these principles determine how stainless steel metal works:

- Chromium (Cr): Although it is not exactly 10.5%, it gives stainless steel a high degree of resistance to rust.

- Larger coins like nickels: This happens about 8-10% of the time. This improves strength and lessens the likelihood of cracking, particularly in acidic environments.

- Carbon (C): Keep the level low (0.03% – 008%). Its resistance to rust increases with decreasing amounts of this carbon.

- Molybdenum (Mo): Some premium stainless steels have about 2–3% of its addition. It helps strengthen the steel’s defenses against corrosion and damage from small flaws.

The Physical and Mechanical Properties of Stainless Steel

Without any defects, stainless steel is a great assistance in the construction and reinforcement of pole posts, crowd control barriers, and other road safety features. That is the reason it is a popular choice for crowd control, home and outdoor security, and other applications because of its special combination of strength, break resistance, and smooth surface. The following explains why stainless steel is essential in various road safety products.

Corrosion Resistance for Outdoor Durability

Equipment for crowd management is commonly used in a range of weather conditions. Because stainless steel is resilient enough to endure rust, rain, snow, and wear and tear without discoloration, it is perfect for roadways, stadiums, airports, and event spaces. This ensures endurance with little support, even in damp or humid conditions.

Resistance to Material and Damage

Pole posts and barricades may be bumped, struck, or pushed by people in busy areas or during an emergency. Because it is made of weak materials, it cannot sustain pressure, bending, or breaking, which helps to keep things safe and orderly.

Aesthetic Appeal for Public Spaces

Stainless steel braces are perfect for places like airports, museums, hotels, and retail centers because of their modern, stylish appearance. Stainless steel barriers and posts also give you a polished, businesslike look while you are working.

Hygiene and Easy Cleaning

In places like hospitals, bus terminals, and airports, it is critical to maintain cleanliness and the convenience of washing. The nonabsorbent surface of Stainless steel helps to reduce the spread of bacteria and viruses by making cleaning easy and effective.

Weather and UV Resistance

Stainless steel is a resistant metal; in contrast to plastic or painted metal, it does not chip, fade, or crack even after being exposed to strong UV light or sunshine for a full day. It is therefore perfect for highway safety measures such as barriers, signage, and traffic guides.

Security and Safety Compliance

By utilizing durable barriers, implant or adjustable poles, and safety posts that adhere to safety and management laws, we ensure the safety and security of our road safety and parking products. Strength and stability are increased when it is loaded or reinforced to withstand large blows.

Recyclability and Sustainability

Stainless steel is a wonderful choice for companies that manufacture crowd control and safety equipment and wish to use eco-friendly materials and processes because it can be completely recycled without a stain.

How Is Stainless Steel Made?

Iron, chromium, nickel, and occasionally molybdenum or other elements make up the majority of the ingredients that make up a stain-free brace at first. These components are combined and roasted at very high temperatures in a powerful oven.

The mixture is treated before it becomes soft in order to remove impurities and create the right chemical composition in line with the exact level of stainless steel resistance needed. After being cleaned, the melted metal is poured into shapes like flat slabs, blooms, or billets.

The stainless steel after refining goes through several processes, such as cleaning it with a particular treatment, annealing (heating it to strengthen it), and descaling (cleaning the surface with a scraper). Ultimately, the stainless steel is cut, shaped, and finished in accordance with its intended purpose, which may include making space for building fronts, healing forms, kitchen sinks, or support posts. The entire process ensures that stainless steel keeps its smooth surface, quality, and ability to withstand corrosion.

Common Types of Stainless Steel Used In Traffic Equipment

1. Austenitic Stainless Steel

Known for its remarkable strength and versatility, this type of stainless steel is the most effective. Austenitic grades, like as 304 and 316, have a high chromium content and a low concentration of other metals. These 304 and 316 are highly used in outdoor activities like coastal cities, stanchion posts, industrial zones, etc.

Because of their exceptional ability to rust, oxidize, and corrode, they are challenging to manage in terms of non-magnetic attributes. Because they are easy to mold and weld, they are perfect for constructing poles, medical documents, culinary equipment storage, and other buildings. Because it contains more molybdenum, 316 is better for coastal or artificial settings, but 304 grade is great for everyday uses.

2. Ferritic Stainless Steel

Ferritic stainless steel, like grade 430, contains chromium but not nickel. This lowers the cost. It is a magnetic that performs exceptionally well in areas with little humid or liquid, such as homes. Its primary applications are in home appliances, automotive parts, and decorative panels. However, ferritic steel is more difficult to shape or weld than austenitic steel, and it performs poorly in corrosive or marine environments.

3. Martensitic Stainless Steel

Because of their strength and hardness, martensitic stainless steels, such as grades 410 and 420, are widely used. These steels are great for making cutting tools, sharp forms, shafts, and valves because of their resistance to high temperatures. They are less resilient to breakdown than austenitic forms, despite being magnetic and resistant to rust. Proper heat treatment is necessary to keep materials from becoming brittle.

4. Duplex Stainless Steel

Duplex stainless steels combine the best features of ferritic and austenitic steels. Because of their special two-part structure, grades like 2205 are incredibly strong and resistant to pitting and cracking. These steels are commonly recycled for use in smoke, lubricant, manufacturing, and maritime environments. They are sturdy and work quite well, despite their challenging construction.

5. Precipitation-Hardening Stainless Steel

This type of stainless steel, like grade 174 PH, is made to be incredibly durable and rust-resistant by a special hardening process. It is used in vital industries like aircraft, nuclear energy, and highly effective machinery. These steels have better mechanical qualities and are probably more consistently generated when heated. They are great when two things, like corrosion and strength, are required.

Comparison of Stainless Steel Grades For Road Safety Equipment

| Grade | Composition | Corrosion Resistance | Common Use | Cost |

| 304 | 18% Cr, 8% Ni | High (general purpose) | Indoor/outdoor | Moderate |

| 316 | 16% Cr, 10% Ni, 2% Mo | Excellent (saltwater/chemicals) | Coastal/industrial outdoor | High |

| 201 | Low Ni, high Mn | Moderate | Indoor/dry areas | Low |

| 430 | 17% Cr | Low to moderate | Decorative/magnetic needs | Low |

Applications of Stainless Steel in Road Safety & Traffic Equipment

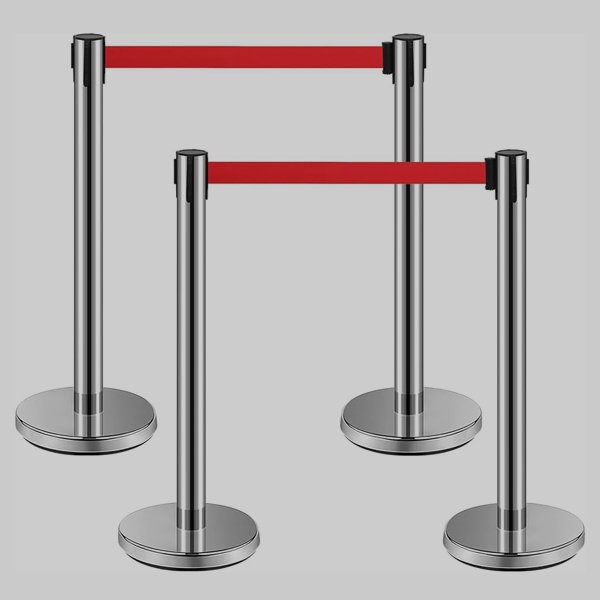

1. Stanchion Posts for Crowd and Traffic Management

Our stanchion posts, made from stainless steel, are commonly used for event management and crowd control. Parking lots, event venues, airports, shopping centers, and roadways where cars stop are common places to encounter these stainless steel stanchion posts.

Because they are visually appealing and corrosion-resistant, the stainless steel stanchions continue to be strong and beautiful in both urban and rural environments. They are perfect for formal settings or high-traffic areas because of their smooth, glossy texture. Whether in the conventional design or with retractable belts, stainless steel stanchions rope help to direct foot traffic and preserve public safety and order. Need customized stainless steel safety equipment? Contact us right now.

2. Safety Bollards for Impact Protection

Stainless steel bollards serve as safety posts to prevent people from being accidentally hit by cars in parking lots, on walkways, and at construction sites. These bollards can be fixed or retracted, and they are frequently used for two major purposes: protecting objects and improving the appearance of structures. Stainless steel is an excellent material for bollards because of its strength and resilience to environmental changes. It can endure rust, dampness, and sun exposure for many years.

3. Parking Delineators and Lane Separators

Additionally, stainless steel is utilized in the production of traffic markers that help taxis navigate parking lots and roads. These consist of posts, curb-mounted markers, and lane dividers. Since these products are exposed to constant driving pressure, stainless steel offers the strength and resistance to rust required to keep them in good shape and functional order for an extended period.

4. Signposts and Road Markers

Sometimes, elastic or flexible markers are reinforced with stainless steel, which serves as a basic support. Strong signposts are often used to support road flags and signs that control and direct traffic in parking lots and on roads. These signs must be sturdy and upright in the face of wind, rain, or bumps. Particularly in areas with high humidity or precipitation, stainless steel resists rust and damage. Due to their durability and ease of maintenance, stainless steel signposts are ideal for outdoor signs that must remain in place all the time.

5. Removable and Lockable Access Posts

In designated parking spaces or areas where bikes are not allowed, metal poles that can be removed or locked are erected. Therefore, stainless steel is an excellent choice for driveways, walkways, and emergency boat lanes due to its robustness and attractive appearance.

6. Wheel Stops and Bumpers

When combined with stainless steel and utilized in outdoor settings or with equipment safety devices and wheel blocks, they are more resilient. Stainless steel helps maintain high quality because less expensive materials may shatter or wear out. Additionally, stainless steel is utilized to make security barriers that let regular traffic flow through while keeping dangerous cars at bay.

7. Emergency Access and Road Safety Barriers

The substance is crucial for guaranteeing human safety because it is incredibly reliable and long-lasting. Stainless steel’s rust resistance also reduces the likelihood of mechanical failure because it complies with eco-friendly practices or requirements.

8. Reflective Studs and Road Accessories

Some sturdy road studs are staying securely in place on the road due to their stainless steel shells. Every night, these are widely used to improve visibility and safety on highways, in garages, and in parking lots. The long-lasting stainless steel allows for strong and reliable security solutions.

Conclusion

The usage of stainless steel increases the longevity, security, and durability of traffic materials. Durable, non-biodegradable materials, such as stainless steel, can extend the life of parking lot signs, posts, and barriers and help keep people safe, particularly in bad weather or close to the ocean. It is not only an economical option to provide durable, high-quality road surfaces, but it also helps to improve the general safety and standard of walkways, parking lots, and roads. Time to look at our wide range of stainless steel items that are available in different forms and sizes.

FAQs

Is stainless steel a single metal?

No, there is not a one substance that make stainless steel single; rather, it is composed of many minerals. It is a mixture of metals, usually containing nickel or molybdenum, but mostly iron and chromium (less than 10 percent). It has stability, strength, and lifespan because of this combination.

Does stainless steel rust?

Yes, but it is not that simple. Because of the chromium in its composition, which creates a thin protective oxide layer on the surface, stainless steel is made to be resistant to rust. This “passive layer” prevents moisture and oxygen from getting to the metal. Nevertheless, some varieties of stainless steel may eventually experience surface rust or corrosion due to specific factors, such as exposure to saltwater, harsh chemicals, or surface damage.

What is stainless steel banding?

For mounting signs and signals, stainless steel banding, sometimes referred to as stainless steel strapping, is a very flexible and affordable option.

What Makes Stainless Steel ‘Stainless’?

Because it creates a coating of compounds on the surface when exposed to air, chromium is what gives stainless steel its distinctive quality. This coating, which inhibits rust and can self-repair in the event of harm, makes the stainless steel more resilient and less prone to stains.

304 vs. 316 Stainless Steel: Which Resists Rust Better?

Compared to 304 stainless steel, 316 stainless steel grade provide better rust prevention. While both types of steel grades are resistant to breakdown, 316 steel has molybdenum, which increases its resistance to chlorides and hostile conditions. It is therefore ideal for usage in marine and coastal situations. Use 316 in harsher outdoor or artificial settings and 304 in interior or dry settings.

Do stainless steel traffic posts meet ASTM standards?

Because they can be tested for impact resistance from both low- and high-speed vehicles, some stainless steel traffic posts satisfy American Society for Testing and Materials (ASTM) standards. Installing traffic posts that have been authorized by ASTM helps guarantee that there will not be any security flaws on your property.

What are the different finishes of stainless steel?

- Grade and composition (more nickel or molybdenum = higher cost)

- Market demand and global metal prices

- Production processes and finishes

- Quantity and customization needs

- Import/export duties and shipping costs

What factors affect the price of stainless steel?

- 2B: Smooth, dull, matte finish

- BA (Bright Annealed): Shiny and smooth

- No. 4 Brushed Finish: Satin-like with visible grain

- Mirror Finish (No. 8): Highly reflective

Galvanized stainless steel crowd control barriers

While the galvanized stainless steel has a zinc coating to stop rust, the stainless steel has chromium, which makes it strong resistant to rust. Most crowd control barriers are made of galvanized steel, which is less expensive but durable.

Are Stanchion posts made of stainless steel?

Yes, In several locations, including airports, banks, and events, the pole posts are indeed constructed of durable stainless steel. Stainless steel stanchions are a popular choice because they are aesthetically pleasing, durable, and resistant to fingerprints and rust. We offer customized stanchion post depending on your design requirements, they are available in clean, glossy, or coated colors.

Does JACKWIN provide customized stanchion posts in different stainless steel grades?

Yes, depending on your needs, JACKWIN manufactures customized pole posts in a variety of grades, including 304 and 316. They offer a range of styles, post kinds, and belt lengths tailored to your particular needs, regardless of whether you need to control crowds on roads or in manufacturing areas.

-80x69.png)