Utility service lines, which include gas lines, electrical cables, water pipes, and communication systems, are crucial for different building projects. Yet, since they are often underground, they may get damaged unintentionally during excavation and building processes. Utility companies and civil engineers use protective measures like a cable cover plate or utility protection covers to minimize these dangers and ensure safety. This article examines the cable cover plate’s objectives, types, and applications in underground utilities protection.

What is a Cable Cover Plate

Cable cover plates, which are also referred to as warning marker plates, protective slabs, or shielding plates, act as strong barriers placed over underground utilities to support weight. They serve as a defense, taking in and spreading the force exerted by bulldozers, taxis, and construction activities.

Cable Cover Plates Manufacturing Process In Underground Utility Protection

1. Workshop Preparation

We utilize advanced technology and a skilled workforce committed to creating unique products and customized solutions for underground utility protection services. Our method ensures that every cable cover plate meets stringent quality standards while being sturdy enough to endure tough underground conditions.

2. Extrusion Process

The process begins in our well-organized workshop. Here, we sort and prepare raw materials like PVC and PE. We focus on key factors such as strength, resistance to challenges, and required flexibility. These materials are shaped in our factory using specialized equipment that carefully forms them into the needed configurations. Our electronic systems maintain consistent thickness, accurate measurements, and a perfect finish through the entire production process.

3. Production Line Operations

We operate Factory System One and Factory System Two at the same time to manage both standard and practical certifications. Whether it’s sturdy PVC plates for protecting electrical cables or flexible PE sheets for telecommunications, each product is designed for handling substantial orders while adhering to essential timelines. After molding, the plates are cut to size and treated to make them thinner and flatter for a proper fit.

4. Quality Control

Quality assurance is central to our production approach. Throughout different phases, our quality control team inspects the dimensions, material, color uniformity, and surface quality. Any mistakes are corrected promptly to guarantee that only high-quality products are sent out. Certified items are taken to the packaging area, where they are carefully boxed, labeled, and prepared for delivery. If needed, custom labeling and color-coded designs can be requested.

5. Packaging

During the shipping process, Jackwin partners with reliable associates to ensure timely and secure deliveries, both domestically and internationally. Once the items reach their destination, we provide assistance with the setup, offering guidance or financial support to make sure the plates are correctly placed over cables or pipes as needed. This whole procedure exemplifies Jackwin’s commitment to providing value, safety, and complete reliability in managing underground utility projects.

Benefits & Purposes of the Cable Cover Plate In Underground Utility Protection

Cable cover plates protect cables, hoses, and pipes from potential harm caused by vehicles, pedestrians, or heavy items.

Enhanced Safety

These plates lower the chances of tripping in busy spaces, ensuring that pedestrians, farmers, and visitors are protected from accidents.

Importance of Load Material

Sturdy cable cover plates can bear the weight of large trucks and equipment as they move over them, making them suitable for areas with high traffic.

Organized Cable Management

Keeping cables neat and separated reduces mess and improves the work setting.

Noticeable Warning Signs

A clear sign, along with customizable markers or logos from officials, makes it simple for workers and passersby to spot and be warned about hidden cables.

Sustainable and Strong

Many cable cover plates are made from tough materials like rubber or polyethylene, which allows them to resist various weather conditions and be reused multiple times.

Adaptable to Meet Your Needs

They can be customized in size, load limit, material, and color to fit the specific requirements of your setting, whether at home or in an outdoor space.

Applications of Cable Cover Plate In Underground Utility Protection

Busy Roadway Crossings

Utilities that lie beneath roads and highways are continually at risk from heavy traffic. Cable cover plates serve to safeguard gas lines, water pipelines, and fiber optic cables by spreading the load from trucks and other heavy vehicles. They help minimize the number of problems by maintaining the quality of the soil around important areas. Typically, reinforced concrete slabs are installed under asphalt roads to protect essential pipelines.

Modern and Informational Websites

In places where large machinery such as excavators and bulldozers is used, brace or composite plates provide temporary support during construction. They aid in preventing errors in project management or work tasks.

Pedestrian Areas and Urban Green Spaces

In sidewalks, parks, or open spaces, less critical plastic or composite plates protect items like power lines or telephone wires from traffic, gardening tools, or light digging. Aesthetic options include plates that have uneven textures or distinctive surfaces, allowing them to harmonize well with their surroundings.

Runways and Roadways at Airports

Runway surfaces need strong protection. Sturdy and durable slabs can bear the heavy weight of airplanes. Long-lasting materials, such as tough, glass-like plastics, can resist harm from de-icing chemicals and other debris.

Railways and Subways

Cable cover plates guard utilities from damage caused by vibrations and heavy pressures. Flexible composite plates can absorb shocks while still being strong. It is crucial to keep temperature fluctuations in mind in underground tunnels, using materials that resist heat.

Best Practices for Installation of Cable Cover Plate In Underground Utility Protection

Depth Placement

- Position the plates at a depth ranging from 6 to 24 inches based on local guidelines and what works best.

- It is important to ensure the plates sit flat and level to prevent the formation of pressure points.

Material Selection

- Choose materials based on how they will be used, for example, using concrete for roads and plastics for recreational areas.

- Employ clear plates with gold strips to facilitate easy navigation with electronic devices.

Combined Protection Systems

- Acquire cable cover plates to use with the warning tape placed above the home plate at a baseball field, and include a safety mesh around it for extra protection.

Compliance with Standards

- It means sticking to the color codes set by APWA and complying with OSHA standards for marking operational items, ensuring safety at construction sites.

- Follow the local building codes regarding handling loads and body positions.

Cable Cover Plate Material Used In Underground Utility Protection

Cable cover plates made from PVC and PE are important in construction and building activities for buried protection, cushioning and insulation, and separation. These safeguarding cable cover plates in utility protection act like warning signs, but they do not have a shiny appearance. They help to keep pathways clear or show where pipes, cables, and ducts are located, whether above or around them.

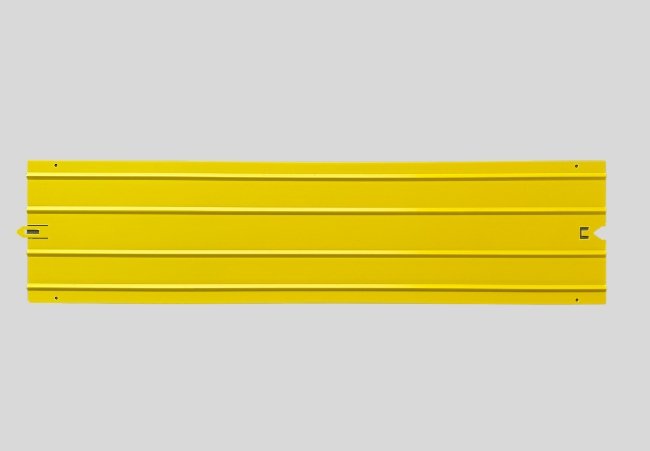

1. PVC Underground Utility Protection Cable Cover Plates

Material: Rigid Polyvinyl Chloride

Plates made from PE and PVC play a vital role in construction and maintenance activities for marking, shielding, and covering underground cables and pipes. These plates act as protective barriers or warning signs that are positioned over essential utilities to prevent accidental damage during digging. PVC plates are often preferred because of their strength, resistance to fire, and durability when exposed to sunlight.

This durability makes them well-suited for uses where visibility and long-lasting performance are important, such as tagging cables, smoke vents, and water pipes. Bright cable cover plate warning signals can also be added to improve safety in these locations.

2. PE Underground Utility Protection Cable Cover Plates

Material: Flexible or semi-rigid Polyethylene

On the other hand, PE cable cover plates provide more flexibility and excellent defense against water and bullets. This feature makes them a great choice for deep burial or building on unstable ground. Additionally, PE plates are lightweight and easy to handle, typically available in rolls, which makes covering large areas easier.

They are commonly used to identify telephone lines, mark cable positions, and indicate paths made of plastic. Utilizing both types of plates can help minimize damage chances, improve maintenance efficiency, and ensure compliance with safety standards. The best option will depend on the specific situation and the type of system being utilized.

Key Comparisons

Feature |

PVC Cable Cover Plates |

PE Cable Cover Plates |

| Weight | Lightweight (e.g., 0.75 kg/m) | Varies by thickness |

| Lifespan | 30+ years | 50+ years (gas pipes) |

| Applications | Cable/pipe protection | Gas lines, utility cables |

| Installation | Easy (modular panels) | Requires fusion/mechanical fittings |

Advice: Choose PVC cable cover plates for cables/utilities and PE for gas and high-pressure utilities.

Need a Custom Cable Cover Plate for Underground Utility Protection?

Why Choose Us

Since 2008, Jackwin has been a reliable cable cover plate manufacturer and cable cover plate supplier for a range of applications, such as managing traffic, parking lots, public events, construction zones, and technical settings. We offer both standard and fully customized cable cover plates to meet the particular needs of your project.

We Specialize in

Our manufacturing facility is certified with ISO 9001 and ISO 14001 standards. The cable cover plates we produce meet BS EN12613 and EN12613 regulations, which guarantee their quality and safety. At Jackwin, we follow strict ISO guidelines. Each order undergoes detailed quality checks, starting from the choice of materials to the final product, ensuring strength, accuracy, and durability under tough conditions.

Width Customization Diversity

We provide a wide range of underground cable cover plates designed to meet different project needs. You can choose widths of 120mm, 150mm, 180mm, 200mm, 250mm, and 300mm, all with a standard length of 1000mm. The narrower options, which are 120mm and 150mm, have a thickness of 1.8 mm, while the wider options—180mm and larger—come with a thickness of 2.0 mm. This arrangement ensures strength and durability, adjusted to your needs.

Time to Invest in Precision: Protect with Confidence

Moreover, our automated production lines create cable cover plates that are usually smooth and precise, reducing the likelihood of human mistakes, which contributes to lasting quality. This automated process improves efficiency in non-metallic underground warning boards, allowing us to offer you more competitive pricing and faster delivery times. Select Jackwin for details about cable cover plates that fit your performance criteria, fulfill your requirements, and stay within your budget.

Conclusion

Jackwin protective cable cover plates can be tailored to meet your unique needs, increasing the usefulness of security and compliance. They can display your company name and brand in vivid colors for easy visibility, offer two distinct design possibilities like bold warning text, and dual-language messages. Additionally, you have the option to select a custom logo, banners, and custom cable cover plate sizes that correspond with the project’s legal requirements. These plates significantly lower the possibility of injury during maintenance or excavation operations by improving physical security and acting as a visual warning to third parties. For a trustworthy and expert solution to safeguard your subterranean infrastructure, discuss your cable cover plate requirements with us now. You can also contact us.

Faqs Section

How many types of material does Jackwin offer?

Customers can select between two types of materials: PE (Polyethylene), which is more flexible, or PVC (Polyvinyl Chloride), which is more rigid. Furthermore, PE plates can be used to improve the visibility and practicality of labels, enabling the creation of custom warnings or labels tailored to particular projects. This variety helps ensure effective and safe protection for sensitive tasks across different industries.

Can we customize the length of the underground cable cover plates?

We offer a variety of size alternatives, including lengths beyond the standard 1000mm, to meet the needs of particular projects.

Can we mark our personalized texts on the underground cable cover plates?

For improved safety, you can include party names, warnings, or two different dual-language texts in a custom publication.

Do cable cover plates comply with industry safety standards?

The best cable cover plates are manufactured in accordance with national and international safety regulations, guaranteeing their dependability and compliance with requirements.

Can these plates withstand harsh environmental conditions?

Yes. Depending on the installation depth and environmental factors, two varieties of PVC and PE plates are designed to withstand liquids, chemicals, soil pressure, and sunshine.

-80x69.png)