The demand for galvanized metals is rising. They are used in many different fields, including building, technology, and transportation. Two of the most popular methods for creating these materials are electro-galvanizing and hot-dip galvanizing. These two approaches yield different outcomes through separate methods and are suitable for a range of applications. If you are debating between hot-dip galvanized and electro-galvanized, continue reading. This article will discuss the main differences between these two intriguing strategies. So, let’s learn: what are they, and which is better?

Overview of Hot-Dipped Galvanized Vs Electro-Galvanized

What is Hot-dipped Galvanized Steel

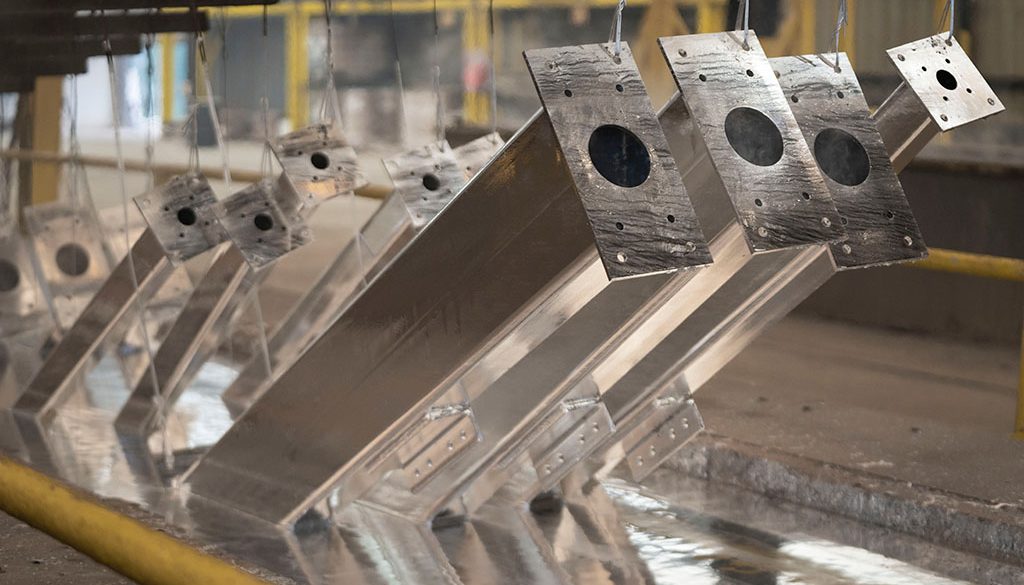

Hot-dipped galvanized steel is produced by submerging steel in liquid zinc. After cleaning, the steel is submerged in molten zinc, which sticks to the steel’s surface. This handle is commonly employed in large industries, especially in areas with sufficient airflow, because of the intense heat involved. In order to promote zinc adhesion, the steel is usually produced with a rougher surface. As a result, the coating offers better coverage for the steel but is thicker and more uneven than electroplating.

What is Electro-galvanized Steel

It is made by immersing the steel in an electrical plating bath. In this shower, zinc coating is applied using electricity. Steel acts as a negative component because zinc particles stick to it. Usually, this preparation is carried out in a safe indoor environment. The electroplating process creates a thin, consistent layer of zinc, giving the surface a smooth appearance. Electrogalvanizing is ideal for applications requiring precision and a smooth finish since the steel used is usually cold-rolled, and the process is precise.

Process of Electro Galvanized vs Hot Dipped Galvanized

Electro Galvanized Steel Manufacturing Process

In hot-dip galvanizing, steel is submerged in a bath of molten zinc to provide a protective coating. This steel will go through several procedures to guarantee that the coating adheres properly and that a strong protective layer forms.

- The product is washed with a strong cleaning solution to remove oil, grease, and debris, which are usually washed out at that time.

- An acidic solution is now used to clean the item. This gets rid of any remaining trash and rust.

- The object has a flux or inhibitor applied to its clean surface. This promotes zinc layer adhesion and inhibits corrosion.

- Until the object’s temperature equals that of the molten zinc, it is submerged in the bath.

- To reduce the temperature of the coated object, quenching (a water shower is used). This helps to preserve the integrity and hardness of the zinc coating.

Hot-Dipped Galvanized Steel Manufacturing Process

Electrostatic galvanizing is a process that uses electroplating to produce a zinc coating. To do this, the steel and a non-working anode must be immersed in a zinc salt solution. Degreasing, a cleaning technique similar to hot-dip galvanizing, uses special cleaning chemicals to get rid of stains, rust, fingerprints, and other debris before the product is put in the electroplating tank.

- The surface of the object may need to be cleaned before the coating is applied. Using acidic solutions to remove rust and oxide from an object’s surface is known as etching or pickling.

- This technique entails sending electricity through an object after it has been immersed in a zinc solution.

- Because the electric current flows from the object, through the solution, and toward a non-reactive component (the anode), the zinc can enter the object and form a protective barrier.

- After the product is coated with zinc, any extra zinc and other contaminants are removed by rinsing it with water.

- One technique that helps stop zinc oxide from being produced in the initial weeks after galvanization is passivation.

Hot Dipped Galvanized Vs Electro Galvanized Key Differences

-

Appearance

Electrogalvanized steel is commonly praised for its smooth and shiny surface due to its use in household goods and automobile parts. The appearance of hot-dipped and galvanized steel is smoother and more mature. This rough look is commonly used in engineering and construction projects, even though it is not the best for increasing productivity.

-

Thickness

Being a traffic safety supplier, hot-dipped galvanized steel has pronounced shimmering spots that give it a stylish look. They are produced during the hot-dip galvanizing process when the molten zinc cools and hardens on the steel surface. Compared to electrogalvanized steel, hot-dipped galvanized steel usually has a thicker zinc coating. It is safer since it weighs more, because more zinc can stick to the heated, falling grip. In contrast, electrogalvanized steel frequently has a thin layer. This difference affects how they behave in different situations.

-

Cost

Electrogalvanized steel is frequently less expensive due to its thinner zinc coating and ease of manufacturing. It is a more affordable option for uses such as interior use, where extreme strength and durability are not necessary. Hot-dipped galvanized steel has a thicker protective layer, which makes it more durable and appropriate for outdoor or heavy-duty applications, despite its higher cost.

-

Corrosion Resistance

Compared to hot-dipped galvanized steel, electrogalvanized steel has far lower erosion resistance. A thicker layer of zinc is produced by hot dipping, providing more protection against moisture and salt. The thin zinc coating deteriorates more quickly when it is exposed to dangerous substances.

-

Life Span

What is the lifespan of electrogalvanized steel? Whether it is advantageous depends on where it is used. For ten to twenty years or more, it might not rust at all. In hot and muggy weather, the thin layer of zinc may deteriorate more quickly, fading after a few years. Hot-dipped galvanized steel requires regular maintenance in severe situations.

-

Durability & Strength

Hot-dipped galvanized steel has a longer lifespan due to its thicker zinc coating. Better defense against deterioration is provided by this thicker layer. This is ideal for complex and difficult jobs. Over time, electrogalvanized steel may lose some of its resistance to wear and stress. Because of its thinner coating, it is more vulnerable to corrosion and physical damage in severe environments. Hot-dip galvanized steel can be more difficult to work with and may need more preparation to achieve adequate paint adhesion due to its rough surface. The flat surface of electrogalvanized steel encourages superior paint adherence.

Applications of Hot Dipped Galvanized vs Electro Galvanized

Hot Dipped Galvanized Steel Applications

- Hot-dipped galvanized steel is very strong and resistant to rust. It is widely used in building materials, support beams, and other essential elements. Because of their extreme durability, open-air structures can be used for outdoor purposes such as stanchion posts, fencing, steel crowd control barriers, and other outdoor equipment.

- Hot-dipped galvanized steel is often used in agricultural equipment, including feed troughs, horse barns, and silos, because it is resistant to severe weather conditions.

Electro Galvanized Steel Applications

- The automotive sector makes substantial use of electrogalvanized steel. Common uses include body boards, bumpers, and other commonly produced parts.

- This coating’s smooth finish makes it ideal for applications requiring great production precision, including electrical components, hotels, and cases.

- Because of its attractive surface, electrogalvanized steel is commonly utilized for interior applications. Products like shelving units, lighting fixtures, and furniture commonly employ it.

How to Choose Electro Galvanized Steel or Hot Dipped Galvanized Steel?

For interior applications such as office equipment, furniture, and home appliances, electrogalvanized steel is frequently the recommended choice. Its sleek and tidy design makes it perfect for places where aesthetics are crucial, and it will function well in a controlled and dry atmosphere.

Using hot-dipped galvanized steel is a smart choice if your project includes exterior constructions like roofs or fences. It has a thicker layer of protection that can resist moisture, rain, and salty air. Examples of hot-dipped steel include our OEM crowd control barriers and stanchion posts used in outdoor activities for traffic safety. Your needs and the situation will determine whether you choose hot dipping or electro-galvanizing. By being aware of the main distinctions, you may make informed decisions and ensure that your metal items will satisfy your demands.

Conclusion

Choosing the right galvanizing procedure is essential to achieving the optimum results. To find out more about the differences between hot-dip galvanizing and electro-galvanizing and to decide which method is best for your project, get in touch with a respectable and reputable metal supplier. Jackwin is a crowd control barrier supplier, offering bulk supply chain solutions to meet your project requirements. Time to bulk quote!

-80x69.png)