Manhole covers are most common seen objects throughout urban roads. However, their weight plays a crucial role. Because installing cover with wrong weight or material can pose serious risks to pedestrians, vehicles, and workers.

That’s why most utility workers, municipal authorities, and urban planners often ask, “How much does a manhole cover weigh?” That’s exactly what this guide discusses. In this blog, you’ll learn everything there’s to know about manhole cover, from its weight, material, to types. And by the end, we’ll also answer few most asked questions related to manhole cover.

What is a Manhole Cover?

A manhole cover is basically a lid which is placed exact over the manhole (a vertical access point to underground utilities like sewers or telecom lines). Municipal governments or utility companies usually install these manhole covers. These covers help protect the underground infrastructure, allow easy access to workers for underground maintenance, and prevent accidents.

What Shape is a Manhole Cover? Why?

A manhole cover shape is generally round, although manufacturers made them in both circular and square shape. However, commonly round shape covers are used widely for safety and practical reasons.

Why? Because a circular cover has the same diameter in all directions. And there are no diagonals (or corners). This means that no matter how much you rotate or tilt, a round cover cannot fall through its own opening.

In contrast, a square manhole cover doesn’t have same uniformity in all directions. Also, the square is longer than its sides. And if you tilt the cover a bit or misalign the cover just right, it could slip through, posing serious safety hazard and damage to underground infrastructure.

What is Manhole Cover Made Of?

Manhole covers, as manhole protectors, are generally made using cast iron, duct iron, or composite material. Here is a more explanation to manhole cover types based on material:

-

Cast Iron

Cast iron manhole covers are the most commonly used material worldwide for city streets. These manhole covers are extremely strong and heavy and can easily withstand and bear heavy machinery and vehicle flow.

-

Duct Iron

A duct iron is the stronger and lighter version of cast iron. These manhole covers are more resistant to vehicle impact and cracking. That’s why duct iron manhole covers are often used where extra strength and longevity are required.

-

Composite Materials

Manufacturers also made manhole covers using composite materials (a mix of plastic or resin). These covers are lighter but offer almost same bearing capacity versus the cast or duct iron. Apart from that, these covers are also corrosion-resistant and are often used in residential or low-traffic areas.

How Much Does a Manhole Cover Weigh?

Generally, the standard range of manhole covers somewhere fall between 100 and 300+ pounds. However, the exact weight of a manhole cover can vary depending on few factors. Like the used material, size, load bearing capacity, and thickness.

For instance, a 36-inch diameter cover made with cast iron weigh around 275 to 400 pounds. In contrast, a manhole cover of exact 36-inch diameter but made using composite materials’ weight fall between 60 and 90 pounds.

What Factors Affect the Weight of a Manhole Cover?

As we mentioned earlier that the weight of a manhole cover varies based on the material, size of the cover, its thickness and load bearing ratings. Among all, the material makes the biggest difference.

For instance, cast iron, which is a most widely used material, is naturally heavy. Whereas, duct iron, composite or plastic ones are lighter. So, the weight of covers vary based on using which material they’re manufactured.

In addition, the larger the size of the manhole cover you choose, the more heavy it will be. Also, the cover’s thickness, which is kept considering bearing capacity of a heavy vehicle, adds more weight.

That’s why it’s important that you not just choose based on manhole fitting. Instead, you should choose after considering the estimate of vehicular traffic in the area and type of vehicles that pass. And then choose the right combination of material, size, and strength to ensure everyone’s safety.

What Types of Manhole Covers are Used for Municipal Works?

Manhole covers used in municipal works, like road construction and maintenance, sewer and drainage system installation, etc. come in different designs. Based on function, location, and access requirements, here are the manhole cover types based on design:

-

Solid Top Covers

Solid manhole covers are fully sealed or closed covers with no holes or slots. They’re ideal for manholes with sewer lines or stormwater systems. Because they have no holes, so the cover blocks odor, water, and gases from escaping. You can install them on main roads, highways, residential areas, and busy city streets.

-

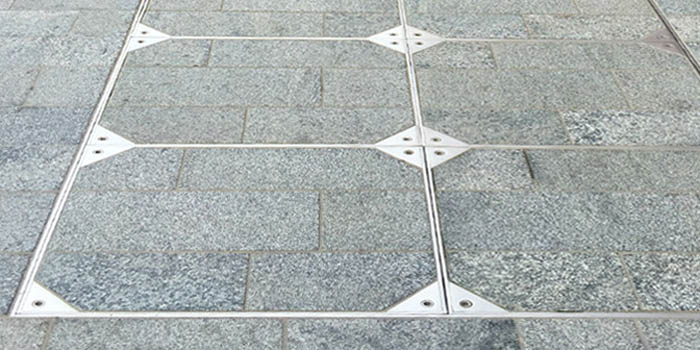

Recessed Covers

Recessed manhole covers, on the other hand, have a shallow tray or space on top where you can place tiles, bricks, or concrete. That’s why facilities mostly install these covers in sidewalks, parks, or plazas to blend with the surrounding surface.

-

Domed Top Covers

These manhole covers are not flat, instead they have a raised or curved surface. The domed (curved) shape actually helps prevent water from flowing off, instead of collecting. You can place them over manholes in rain-prone or flood-risk areas.

-

Ventilated Covers

Ventilated manhole covers generally come with slots or holes. These holes in the cover allow airflow or gas release and manage underground infrastructure ventilation. You can install these covers for electrical vaults, telecom chambers, or areas that need ventilation.

-

Locking Covers

As the name tells, these covers have a locking mechanism. You can use them for fiber optic lines, electrical systems, or restricted municipal areas. You can even install them where there’s a theft of manhole covers is common.

Why Does the Manhole Cover Weight Matter and How Does It Affect Road Safety?

The manhole cover weight matters the most in terms of road safety. Because a manhole, which is a deep vertical underground infrastructure, cover fully seal the manhole. And if you place an incompatible or low-quality manhole cover, it poses serious dangers.

Let’s understand it with this: If you install a lightweight manhole cover in a high-traffic area, here’s what can go wrong:

- When heavy vehicles (buses or trucks) go over the cover, due to pressure, the cover can move, flip, or even open a hole in the road.

- And if the hole opens, it can pose a serious hazard to all road users. Pedestrians can fall or get injured. Or a vehicle’s tire can get stuck.

- Even lightweight covers are easier to steal or tamper with, which increases the chance of accidents.

- On top of that, in case of an accident, your facility might be held accountable. And you’ll end up facing serious financial and legal consequences.

That’s why municipal authorities or road repair contractors like you should always choose a load-rated and weight-appropriate cover. Also, you should keep road condition (like sidewalk, street, or highway) and possible traffic volume in mind while making manhole cover selection.

What are Manhole Cover Standards? And What are They Used for?

In Europe and several countries, the BS EN 124 standard is followed, which dictates guidelines about where municipal and road authorities should install which load-rated and grade manhole cover. This standard defines six load classes (A15 to F900), categorized based on specific environments and weight requirements.

In the next section, you’ll learn about most common classes:

-

BS EN124 A15 Class

Manhole covers in the A15 class have a load-bearing capacity of 15 kN (1.5 tonnes). That’s why you should use manhole covers of this class only in pedestrians areas where vehicles are not expected like footpaths, gardens, and other non-vehicular areas.

-

BS EN124 B125 Class

B125 class manhole covers, on the other hand, have the 125 kN (12.5 tonnes) load-bearing rating. They are ideal for use and installation in light and slow-moving traffic areas, like residential driveways, private car parks, and small access roads.

-

BS EN124 C250 Class

C250 covers can withstand a heavy load of up to 250 kN (25 tonnes). Since they have high bearing capacity, so you can use these manhole covers in places where traffic moves slowly and also where vehicles frequently cross over manholes. Like curbside drainage, commercial loading zones, and paved shoulders.

-

BS EN124 D400 Class

Compared to all above, D400 class covers are heavy-duty. These covers have the bearing capacity of up to 400 kN (40 tonnes). You can use these covers for high and heavy vehicular traffic areas. Like main roads, highways, industrial zones, and busy intersections.

Conclusion

How much does a manhole cover weigh? It entirely depends on the material used in its manufacturing and its size. Also, the weight and load-rating of a manhole cover plays a critical role in ensuring both road safety and road users’ safety.

At JACKWIN, we understand how crucial it is to choose the right manhole cover based on environmental conditions and weight requirements. That’s why, by considering the cover types based on material and design and BS EN 124 load classification, we explained in this guide, you’ll be able to make an informed and safe decision.

FAQs Related To Manhole Cover Weigh

-

Why are manhole covers so heavy?

Manhole covers are heavy because they are designed and meant to be like this. The heavy weight ensures that the cover stay in its place, doesn’t move, hence preventing accidents.

Heavy manhole cover also prevents unauthorized access to underground infrastructure. Since they’re heavy, so they can’t be lift easily, instead specialized lifting tools are needed. Apart from that, they’re also made heavy to meet load-bearing standards.

-

Can you install a manhole cover without tools?

You cannot, and even you should never try installing the cover without tools. Even though some lightweight composite covers are easier to handle, you still need basic tools. The tools actually help you level the cover frame, secure, and properly align it with the surface.

-

What tools do you need to install a manhole cover?

Here’s a compiled list of tools you might need in your work zone:

- Crowbar or lifting key

- Spirit level

- Shovel or trowel

- Either concrete or mortar mix

- Rubber mallet or hammer

- Safety barriers

- High-visibility vest

-

How do you install a manhole cover?

To install a manhole cover securely, follow these simple steps:

- First, remove the old cover and clean the entire area.

- Next, using a spirit level, level the frame.

- Once leveled, apply mortar or concrete around the frame base.

- Then, securely place the new cover onto the frame.

- Now leave the setup for 24–48 hours (if concrete is used).

Lastly, step over the cover or gently press on it to ensure that the cover is firmly placed.

-

Do composite covers perform as well as cast iron?

Yes, composite covers perform well or sometimes even better. However, it also varies depending on the manhole cover application.

Since composite material-made manhole covers are lightweight, corrosion-resistant, and non-conductive, you can use them in low to medium traffic or during cable installation or in harsh environments. However, for high-traffic zones (like highways), cast iron is recommended.

-80x69.png)