As a road construction or maintenance facility, you often have to use reflective glass beading to make road markings more visible and brighter. But if you choose the wrong type or low-quality beads, drivers won’t be able to see lanes that pose more accident risks in low-light conditions.

That’s why we’ve crafted this guide for road contractors, engineers, and construction facility managers to help you understand how to choose reflective glass beads for road markings. Our aim is to make you aware of all the factors, meet safety standards, and reduce long-term costs.

What Are Reflective Glass Beads?

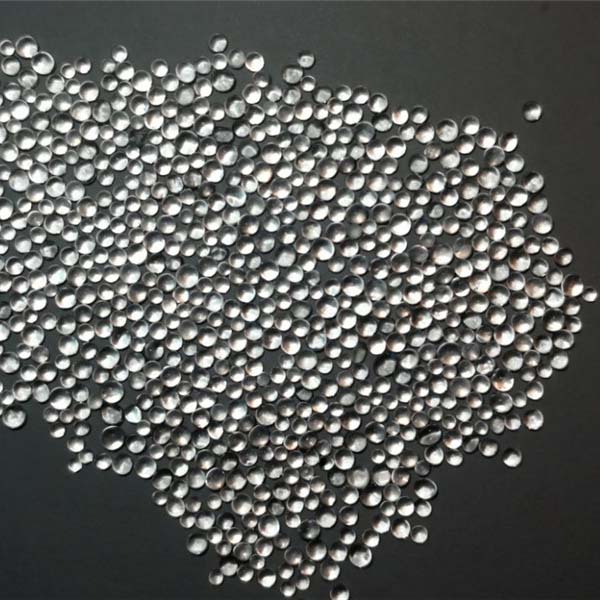

Micro reflective glass beads are basically small, spherical glass particles. Road or highway construction facilities typically use them over road markings to enhance the lanes’ visibility (like lane lines, pedestrian crossings, and traffic symbols), especially in low-visibility conditions.

Because these glass beads have the tendency to reflect the light, which is why glass beads used in road marking. Actually, when the vehicle’s headlights hit these beads, the light reflects directly back toward the driver’s eye.

This retro reflective glass beads effect in result makes the markings appear brighter. This way, these beads help drivers identify lane boundaries, drive within their lanes which ultimately reduces accident risks.

What are Reflective Glass Beads Made of?

Jackwin reflective glass beads are made using recycled glass, which is the same basic material used in making glass bottles and windshields. During manufacturing, we melt this material, form it into tiny spheres, and then cool them to create a firm bead structure. Then, these glass beads for striping (meaning embedded in marking paint) are used.

Understand Glass Beads vs Crystal Beads

Several road contractors confuse glass beads and crystal beads, which is why it’s crucial for you to first understand the difference, so you don’t choose the wrong material. Although they both are same in composition, they differ greatly in purpose and performance.

Crystal beads are brightest, more clear, heavy and expensive. While glass beads are made from recycled glass, are lightweight, less clear than crystal beads and are affordable.

Also, crystal beads are mainly used for decorative, jewelry and crafts stuff, while glass beads are used for road safety products like road markings, signages, marking tape, etc.

How to Choose Reflective Glass Beads for Road Marking?

Choosing Reflective Glass Beads for Road Marking

Choosing the right reflective glass beads basically depends on your requirements. Like which bead application type you prefer, bead size, roundness, coating, and refractive index (RI). Your selection of reflective beads for traffic paint also depends on the road condition you plan to mark as well as your budget.

Now let’s discuss each factor and understand glass beads for road marking specification that helps you decide on how to choose right reflective glass beads:

Choose By Reflective Glass Beads Type

There are basically two types of road marking reflective glass beads:

- Drop on Glass Beads for Road Marking:

As the name explains, these beads are drop or sprinkle over freshly applied wet paint or thermoplastic on the road. And once marking dries, they provide immediate retroreflectivity. You can use these glass beads for line striping on highways, intersections, pedestrian crossings.

- Premix Glass Beads:

These beads are mixed directly into the road marking material (like paint or thermoplastic) before application. And whenever the top layer wears down over time, new beads become exposed. Means, long-term visibility. You can use these beads in areas with moderate-to-high traffic.

Choose By Glass Traffic Beads Size (Grading)

Glass beads come in various sizes. You can even get customized particle sizes of beads to your requirements from Jackwin. The grading (means beads size) directly affects beads reflectivity and application quality. So you must choose it wisely. Here is the general breakdown of sizes.

| Size (Approx.) | Use Case | Reflectivity |

| 100–300 microns | Fine Markings/Thin Lines | Medium |

| 300–600 microns | Standard Markings/Thermoplastic Lines | High |

| 600–850 microns | High-Performance Markings/Wet-Night Visibility | Very High |

| 850–1400 microns | Large Surface Markings/Airport Runways | Very High |

Choose By Refractive Index (RI)

The refractive index (RI) is actually a measure of how much light bends after it enters the reflective glass bead. If we say in simpler words, RI tells how effectively a certain bead has tendency to reflect a vehicle’s headlight back to the driver. Here’s a general breakdown of RI:

| RI Type | Reflectivity Level | Common Uses |

| Standard (1.5 – 1.6) | Basic brightness | Low-traffic roads, temporary markings |

| Medium High (1.7) | Enhanced brightness | City roads, highways, expressways |

| Very High (1.9+) | Maximum-level brightness | Highways, airports, runways |

Choose By Roundness

For glass bead pavement marking you choose, ensure they must have at least ≥ 80% spherical to reflect light efficiently. This percentage ensures the maximum reflectivity. Because if you choose flat, irregular or poor-quality beads, they won’t reflect properly which actually defeat the bead’s purpose.

Choose By Coatings

Manufacturers now made reflective beads with different coatings to meet local standards of glass beads for pavement marking. And also enhance beads’ adhesion and durability. Generally, these are the beads coating options you might find:

- Silicone Coating: It improves strong bonding between the bead and the marking surface. In result, beads doesn’t detach from the road, leading to longer-lasting visibility.

- Adhesive Coating: These are specifically designed to improve stickiness. And especially used with solvent-based or cold plastic paints which prevent falling off prematurely.

- Dual Coating: This is the mix of both silicone and moisture-resistant coatings. Means, beads offers strong adhesion and weather-resistant properties.

Note: While choosing, always ask your supplier if the beads are coated. Also, are they compatible with the specific road marking material you’re using?

Match the Beads with Road Conditions

It’s also important that you consider the environmental and traffic volume factors of a certain road where you plan to use reflective glass beads for paint. Because not all beads are the same, and an environmental factor directly affects the beads’ performance. Here’s a quick selection guide:

- For High-Traffic Roads (Like Highways, Urban Areas):

You should use durable, high-coating beads that can handle heavy wear and tear. You can also go for dual-coated or larger beads. As they work well for maximum reflectivity and longevity.

- For Low-Traffic Roads (Like Rural or Residential Streets):

We suggest you go for standard beads or smaller sizes. As they won’t wear down as quickly.

- For Wet or Humid Areas:

You should select beads with water-resistant coatings. So that they effectively sit during application and ensure clear reflectivity in rainy conditions.

Need Help? Contact Jackwin support team today, and we’ll help you choose the right glass beads for your road marking project!

Evaluate Cost vs. Performance

As we mentioned earlier that your reflective glass beads for road marking paint selection may also vary based on your budget. So know that if you go for cheaper beads, they may work fine in start but after a certain period, they start to wear, loosen and doesn’t reflect the light towards driver’s eye.

That’s why it’s smarter to invest in high-quality beads that reduce rework, increase visibility, and meet safety regulations.

What is Glass Beads for Road Marking Price?

The price of reflective glass beads for road marking can vary depending on the factors we discussed above. Like beads’ type, refractive index (RI), size grading, as well as the packaging quantity (per kg, per ton, or per bag) and the supplier you choose.

Generally, the standard retro reflective beads price range between $300 – $500 per ton. For medium RI (1.7) beads, the price usually falls around $450 – $600 per ton. The higher the RI, packaging volume, or change in the beads coating, the cost increases and vary.

If you’re looking for road marking glass beads at competitive rates, it’s a smart decision to purchase them directly from wholesale suppliers. This way, you will get high-quality materials in bulk at factory-level pricing.

Best Reflective Glass Beads Supplier & Manufacturer

JACKWIN is one of the industry-leading Chinese road marking glass beads manufacturer and wholesale supplier. We offer complete range of road marking glass beads that comply with EN1423/EN1424 (Europe), AASHTO M247 (USA), Type I II III, BS6088 (UK), Australian A, B, C, D, KSL 2521 NO.1 and 2 (Korea)standards.

Whether you need airport quality reflective glass beads, drop on glass beads, glass beads for thermoplastic road marking paint, reflective glass powder, highway glass beads, or reflective glass beads for traffic paint, JACKWIN is an excellent choice. In addition, Jackwin can also supply 3m reflective glass beads at competitive factory prices.

We can also design custom glass beads for road marking factory on customer’s demand. We also give options to contractors to get free samples for your satisfaction and testing. For bulk orders, custom beads, or help on beads selection, contact us today to get an instant inquiry!

Conclusion

Choosing reflective glass beads for road markings are very simple if you know what type of beads you actually need. That you can actually analyze by going through the factors we described in this guide like beads type, size, RI, roundness, and road conditions.

JACKWIN is the supplying reflective beads to 200+ contractors across countries. If you’re not sure of what reflective glass beads to choose, reach to us, and we’ll help you make an informed decision.

-80x69.png)