Rubber and Plastic Wheel Chocks for Sale

We supply and offer various types of wheel chocks at competitive wholesale prices, including various materials, such as rubber, plastic, steel, aluminum, and wood. Our versatile wheel chocks are designed to meet your trucks, cars, SUVs, boat trailers, motorcycles, aircraft, and other vehicles.

What is the JACKWIN Wheel Chock?

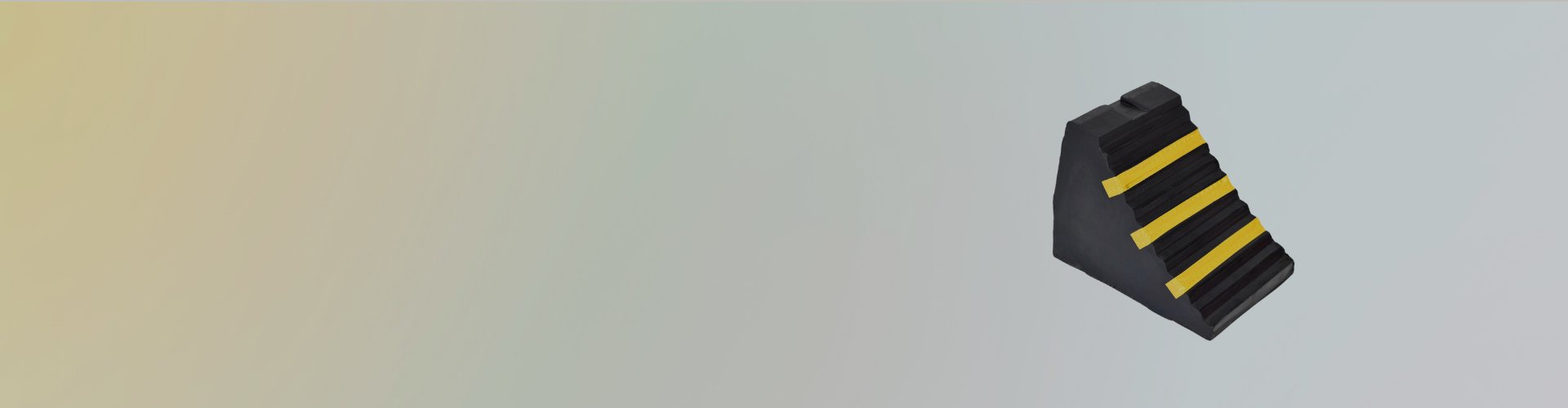

JACKWIN wheel chock is a wedge-shaped safety device made of rubber, plastic, metal, or wood. It prevents forward or backward wheel movement from causing personal injury or property loss, greatly improving safety. It is mainly used in various vehicles, industrial equipment, aviation aircraft, and railway track industries.

Wheel Chocks By Features

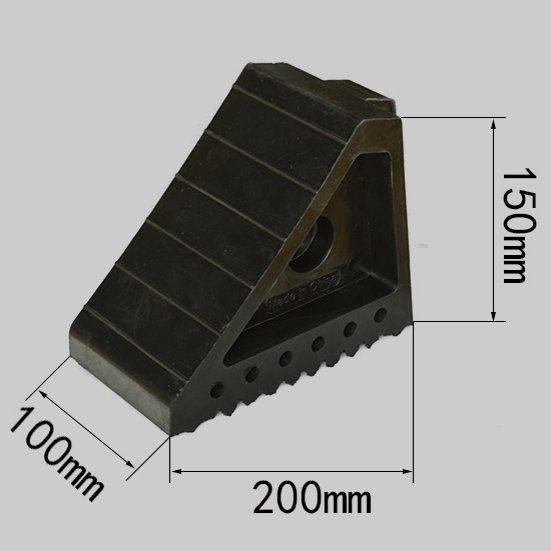

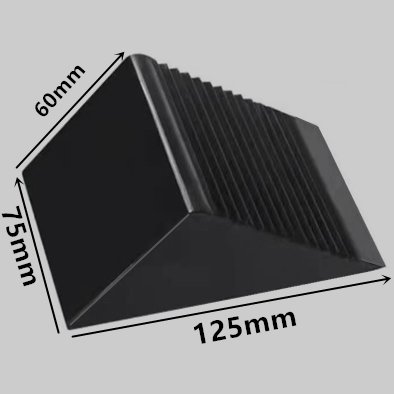

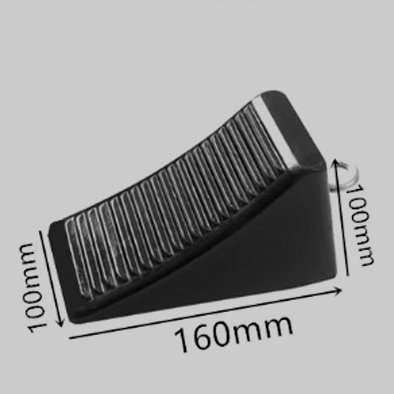

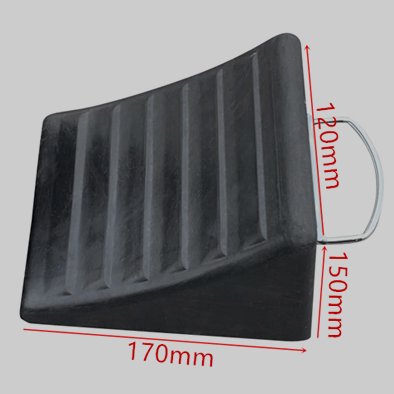

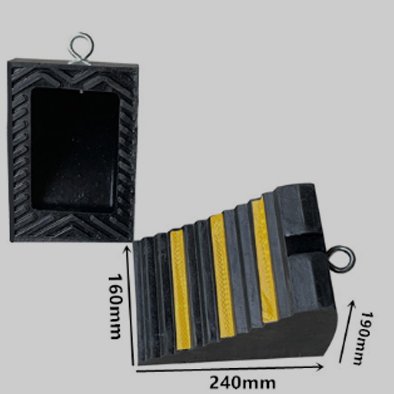

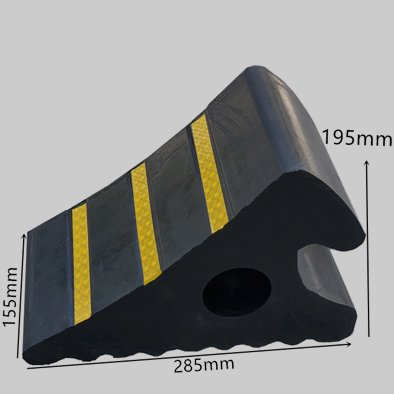

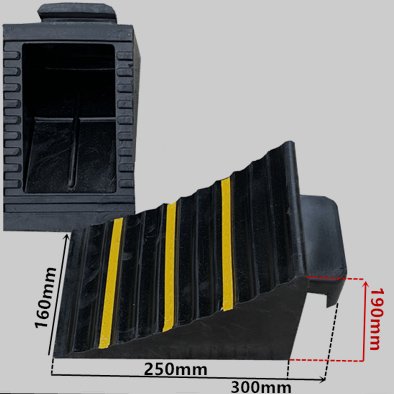

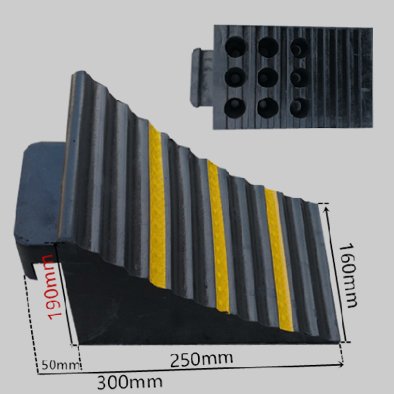

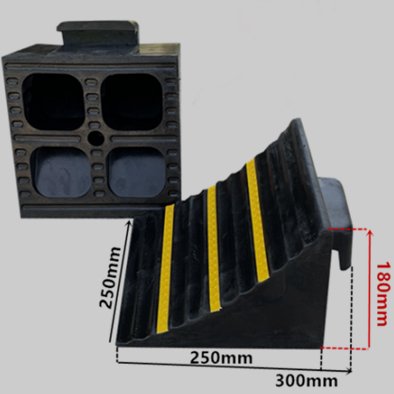

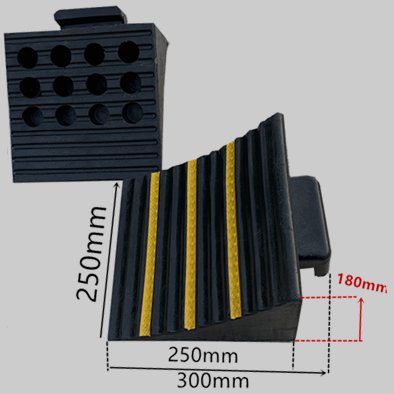

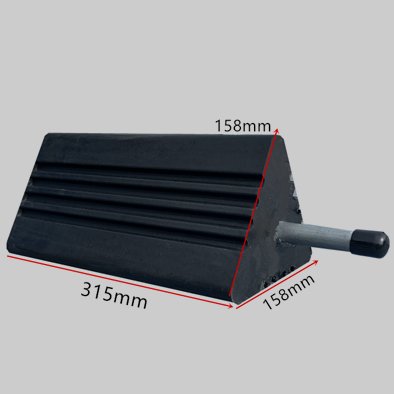

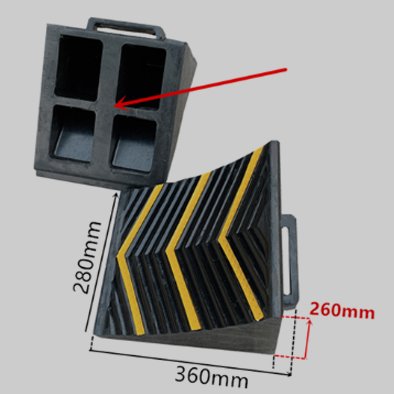

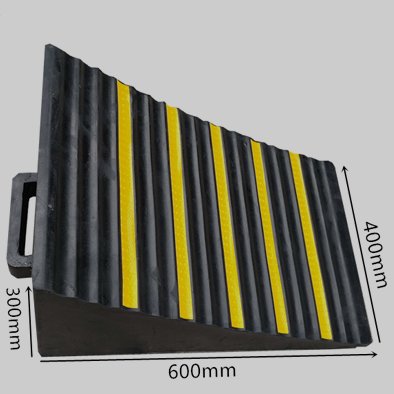

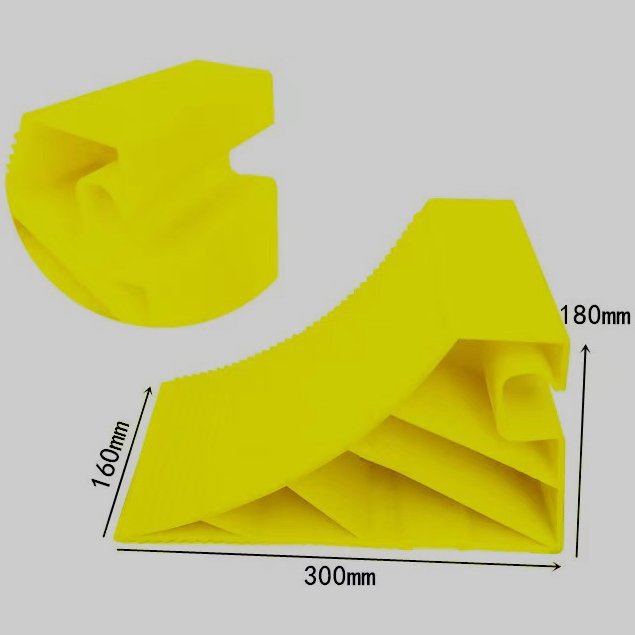

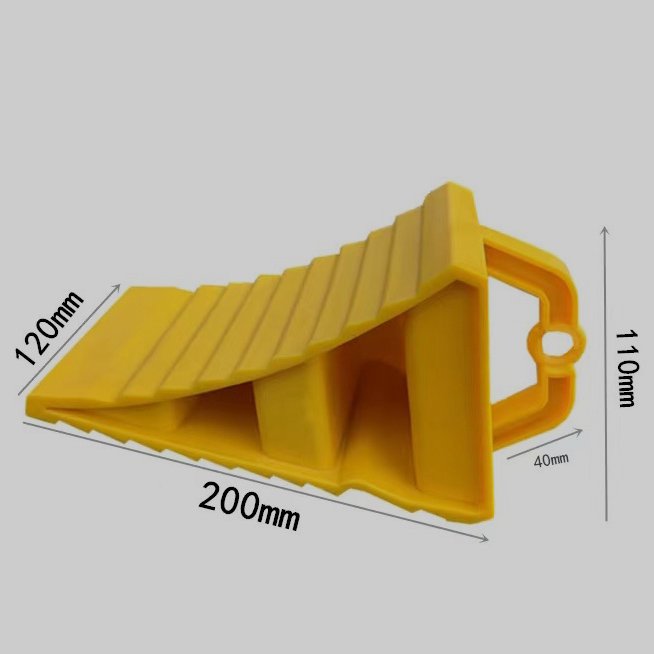

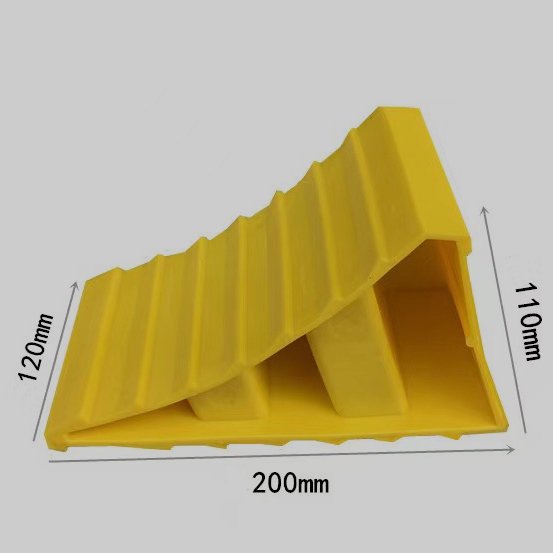

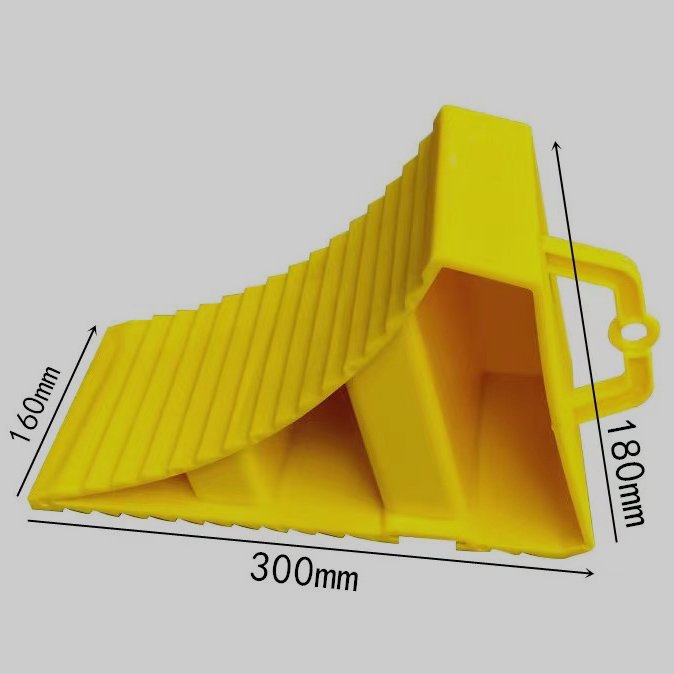

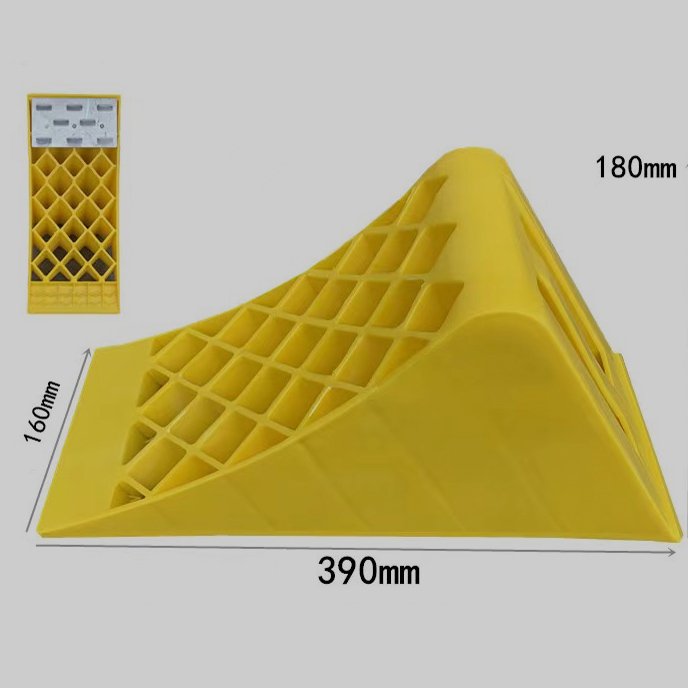

Browse the following JACKWIN rubber and plastic wheel chocks in various sizes, designs, and applications. We can also design and customize any size and shape of wheel chocks according to your graphics. Your brand logo can be debossed on wheel chocks if you reach JACKWIN MOQ, send your inquiry now.

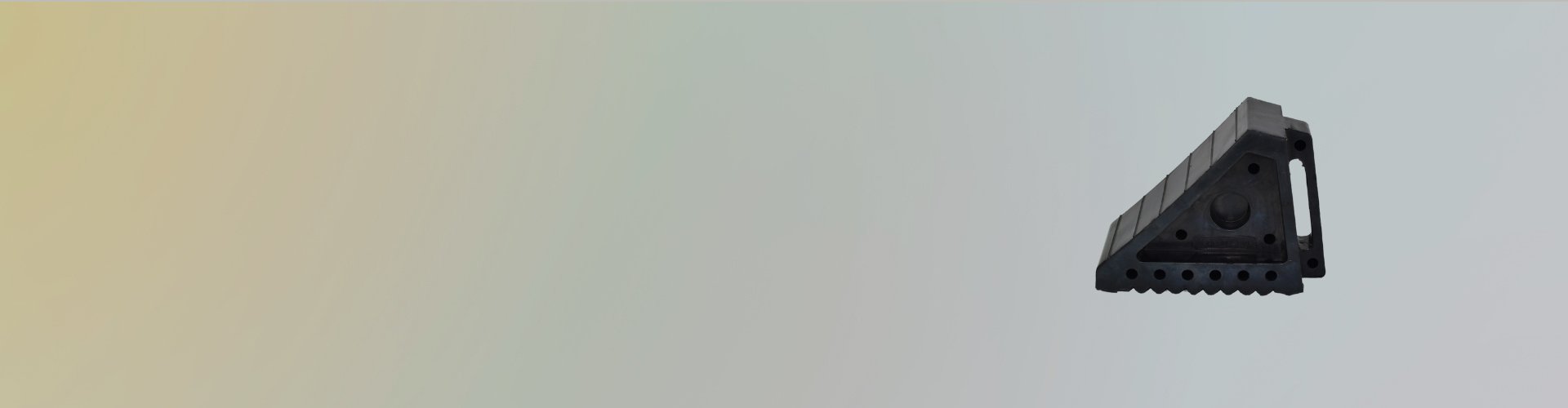

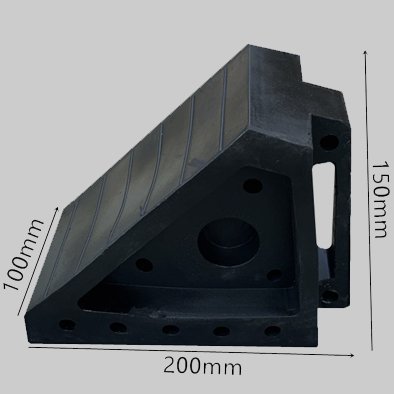

Size 160x100x100mm, 0.8kg, recycled rubber

Wheel Chock Feature Box

Discover JACKWIN wheel chock’s performance features to save your costs and reduce your losses from your projects.

versatile texture, anti-slip surface.

max up to 44 tons of stress for tank wheels.

withstand high and low temperatures in all weather conditions in any country.

withstand X-rays without aging or fading.

resistance to oils and other solvents.

resistant to tears, abrasions

visible yellow safety colors, and reflective in low light conditions.

easy to carry and remove.

Customize Your Unique Wheel Chocks

JACKWIN offers customization for special and unique wheel chocks no matter whether you prefer rubber, polypropylene (PP), wood, aluminum alloy or iron wheel chocks, we can provide unmatched customization services to meet your requirements.

Aircraft Wheel Chocks Specifications

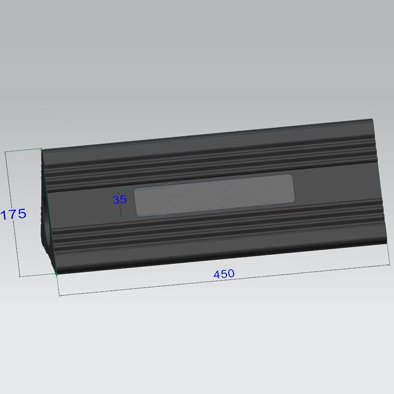

JACKWIN supplies and customizes wheel chocks in various sizes for small to large airplanes. Aviation wheel chocks are usually made of rubber because rubber has good anti-slip properties and good wear resistance. In addition, unlike the wheel chock used on ordinary cars, it must be equipped with a rope connecting a pair of wheel chocks. The sizes we supply are as follows:

- Small aircraft wheel in 3″, 4″ and 6“ lengths.

- Medium aircraft wheel in 7″, 10″, 12″ and 15″ lengths.

- Large aircraft wheel in 18″, 21″, and 24″ lengths.

How to Choose the Right Wheel Chock?

You have just browsed many wheel chocks from JACKWIN, but you may still be confused and don’t know how to choose a wheel chock that suits you. JACKWIN provides some factors and suggestions for selecting wheel chocks as a professional wheel chock manufacturer and supplier.

- First, you need to consider the wheel’s width and diameter, which will determine the size of the wheel chock you need to purchase.

- Second, you need to consider the load-bearing size and the type of vehicle, such as cars or tanks, trucks or aircraft, because JACKWIN’s wheel chocks are heavy-duty and lightweight for you to choose.

- Finally, it is the material selection. Rubber and plastic wheel chocks are the best-selling wheel chocks on the market, so you need to position your market and decide which customers your customer group is, so you can decide what material to choose.

Recursos

Know more product specifications? Just View and Download JACKWIN complete catalogue by clicking link.

Know more about JACKWIN products and company? Just click video link, you can get more than you think.

Rubber Wheel Chocks VS Plastic Wheel Chocks

JACKWIN rubber and plastic wheel chocks are the two most popular on the market. What are their advantages and disadvantages? Let’s discuss them together.

- Rubber wheel chocks are made of recycled rubber. They are heavier than plastic ones, and large-sized wheel chocks are more suitable for heavy trucks, tank trucks, and aircraft.

- Plastic wheel chocks have two materials in the market. One is polypropylene (PP). It is rigid, lighter, and easier to carry. It has the best cost performance and is suitable for lightweight vehicle wheels. The other is polyurethane (PU). It has better flexibility, higher density, and is heavier than PP. It is suitable for heavy vehicles and aircraft. Although both are plastic, they can resist bad weather conditions, are UV-resistant, and do not easily fade.

In short, rubber and plastic wheel chocks have strengths and weaknesses in application, so they are very well-suited to their respective markets. If you still have concerns, please contact the JACKWIN sales team.

Key Applications of Wheel Chocks

JACKWIN wheel chocks are used in many scenarios. Below we share some key application scenarios.

When transport vehicles are parked to load and unload goods, wheel chocks need to be used to stabilize them and prevent them from rolling away.

Wheel chocks are mainly used for container trailers at docks, and they are needed for loading and unloading containers.

When aircraft are parked or maintained at airports, the aircraft’s wheels need to be fixed.

JACKWIN Production Capacities

JACKWIN has 3 rubber production and 2 plastic production workshops, which can escort your wheel chock orders. Our daily output can reach 2000pcs to meet your requirements for fast delivery.

Customers' Feedbacks

Yes, we will provide a 2-year quality guarantee for the wheelchocks.

We can provide samples free of charge on our stock; you need to afford the shipping.

Our standard package is bulk in pallets, and also we can supply carton box packages with printing if you have special requirements.

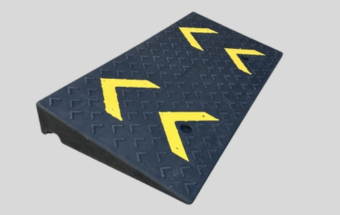

Related Product

JACKWIN Wheel Chock Use Instruction Manual Guide

Please follow the guide below to ensure your safety when using JACKWIN wheel chocks.

- Step 1: Choose the correct wheel chocks (the size and wheel width must match and the load must also match, which is the key to safety)

- Step 2: Park your car in a suitable location and remember to apply the parking brake.

- Step 3: Observe and make sure your left and right wheels are on the same level. If they are not level, the car may roll over even if you install wheel chocks.

- Step 4: Wedge your chocks into the back wheels and push them in with your feet to secure them.

- Step 5: Place your chocks into your front wheels, making sure your car won’t roll forward.

-80x69.png)