In-house Production Capacities

JACKWIN is a leading manufacturer and exporter of products related to traffic, roads, parking, events, work zones, and workplaces.

- Factory ISO9001 & ISO14001 audited.

- Compliant with CE certification.

- Over 16 years of manufacturing and exporting experience.

- Served over 20,000 customers in over 70 countries.

- Accept MOQ (Minimum Order Quantity) and fast shipment.

Manufacturing and Supplying Various Raised Pavement Markers

JACKWIN offers and wholesales various types of pavement markers at competitive factory prices, including reflective/wired/solar-powered LED pavement markers, ceramic/aluminium/glass/stainless steel pavement markers, 3M raised pavement markers series 290, and temporary raised pavement markers.

Various Types of Raised Road Markers for Sale

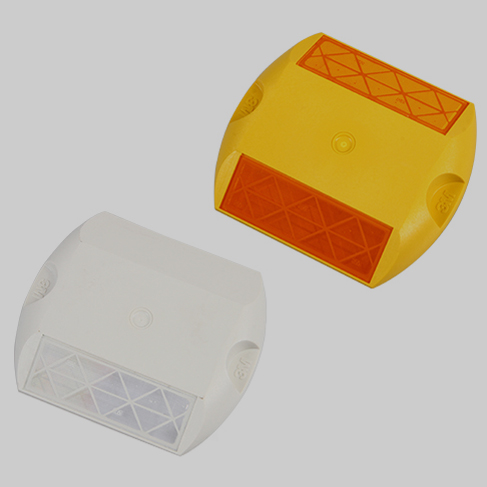

Made of ABS and PC for lens, high impact resistance, installed with A/B glue.

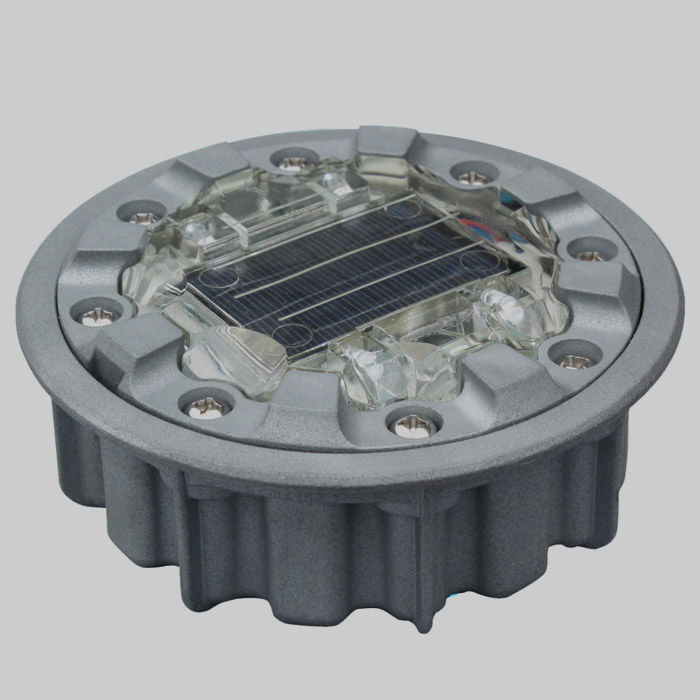

Heavy-duty 40-ton weight capacity, solar-powered rechargeable battery.

Solid base or filling-sand for options, with cost-effective prices.

Military grade plastic and polycarbonate for lens, withstands over 40 tons.

Available colors in yellow and white, and reflective or non-reflective.

Solar power supply, optional GPS synchronous flashing and shooting star.

Solar power and A/C wire supply for options, made of aluminum material.

Tempered glass in red/yellow/white/blue/green, impact capacity 30 tons,

Made of impact PC material, solar power with double reflectors.

Size 100x100x20mm, with double reflectors, fluorescent glow light.

Offers various sizes of reflectors made of PMMA material.

Made of high-quality aluminum with glass bead reflectors.

- Color

- Size

- Type

- Material

Reflective raised pavement markers for sale from JACKWIN come in multiple colors according to internation traffic marking regulations and standards:

- White: They are used for lane markings or to mark the right pavement edge.

- Yellow and orange: They separate traffic moving in opposite directions and mark the left pavement edge on one-way roadways.

- Yellow: Yellow markers can supplement yellow markings for two-way left turn lanes.

- Blue: Blue markers indicate the location of fire hydrants.

- Green: This type is used to indicate that emergency vehicles are authorized to open gates to enter a gated community.

- Red: Red markers typically indicate areas near traffic.

JACKWIN road raised pavement markers are available in 2-inch, 4-inch, 6-inch, and 8-inch sizes and in shapes of square, rectangle, oval, and circle.

- Reflective

These raised pavement markers have two lenses or sheeting that work as retroreflectors with vehicle headlights, making them visible in nighttime or rainy weather. Most have reflective surfaces on both sides for marking the center of a lane and to guide drivers in both directions. These are sometimes named as retroreflective raised pavement markers and reflective pavement studs.

- Non-reflective

These markers (such as those made of ceramic or plastic without reflective elements) are less effective at night, but work well during the day.

- LED emit light(solar power or wire by A/C or D/C)

These marker is made of glass, aluminium, or plastic, built with solar panel, electronic board and a rechargeable battery.

- Snowplowable

These markers are designed with a metal housing to protect them from damage during snow plowing activities and are used in Northern and Midwestern states.

- Non-Snowplowable

These are used in the southern and western United States, where snowfall is not a major concern, and are applied directly to the road surface.

- Convex Vibration Lines (Botts’ dots)

Some markers have raised jolts, coated with pavement-reflective material to alert drivers when they are leaving their lane.

Raised pavement markers are made of various materials, including ceramic, plastic, aluminum, stainless steel, concrete, glass, and reflective thermoplastic paint.

Our Production Methods

JACKWIN raised pavement markers production varies depending on the materials used, browse the following:

- Aluminum pavement markers are produced using cast aluminum. First, the aluminum ingot is melted at high temperature and poured into a mold. Second, it is cooled and formed. Third, the edges are polished and painted. At last, the circuit board or reflector is assembled.

- Plastic raised pavement markers are produced using plastic injection molding. First, the shell and reflector are injection molded using an injection molding machine and a mold, and then assembled.

- Glass raised pavement markers are produced by heating the glass material into shape by pressing, then cooling, shaping, and tempering.

- Ceramic raised pavement markers are produced by dry pressing, heating, and cooling.

Components Assembling

The most complicated assembly of JACKWIN raised pavement marker is the solar-powered pavement marker, which includes the welding of circuit board components and chips, the installation of solar panels and batteries, etc. After installation, it must undergo rigorous functional testing and quality inspection before proceeding to the next packaging stage.

How to Choose the Right Raised Pavement Marker?

JACKWIN supplies various types of raised pavement markers in different materials. Below are 5 key factors to help you choose the correct raised pavement markers.

- Climate and Snowplowing Conditions: In areas with significant snowfall, snowplowable raised pavement markers are necessary, although some states avoid raised pavement markers altogether due to snowplow damage. In regions without snow, non-snowplowable raised pavement markers are suitable.

- Depending on Roadway Type and Traffic Volume: Some STAs use raised pavement markers on all state-maintained highways, while others use them selectively based on factors like roadway type, traffic volume, illumination, safety record, and speed limits.

- Depending on Visibility Requirements: Raised reflective pavement markers are better for visibility compared to non-reflective or recessed markers (particularly in wet conditions and at night).

- Durability and Maintenance: The raised position protects markers from some wear and debris, which increases their lifespan. You can order military-grade raised pavement markers for maximum durability.

- Specific Applications: The color of the marker should comply with your local standards to indicate lane markings, separation of traffic direction, or the presence of hazards or access points for emergency services. Choose colours based on your needs.

Our Production Line Gallery

We have 4 production lines for specially manufacturing and assembling raised pavement markers. Please browse the following images of the production line.

What Are Raised Pavement Markers?

Raised pavement markers, also known as road studs, cat’s eyes, delineators, road turtles, road marking studs, and road reflectors, are small road safety devices used on roads, bridges, highways, tunnels, and pavements to guide drivers, particularly at night and in poor visibility conditions. Their purpose is to act as reflectors and enhance the visibility of lane markings, as well as highlight the road layout.

Our standard lead time is 15 days after receiving your payment, although this may vary depending on the quantity of your order.

Each marker is packed into an inner box, then massed into export cartons by pallets for shipment.

-80x69.png)