Road safety is a top priority in most countries. Hence, it is crucial to use the right materials when making safety and traffic signs. The most popular materials are reflective and retroreflective sheeting.

But which one should you choose? In this article, we provide a detailed explanation of the differences between reflective and retroreflective sheeting.

Basic Definitions

While most people use these two terms interchangeably, it is essential to note that they have different meanings. Additionally, they are suitable for different types of applications.

What Is Reflective Sheeting?

Reflective sheeting is a material that can reflect light at night or in low-light conditions, made of PET, PMMA, or PVC sheet and glass beads or fluorescent powder.

Reflective sheet reflects light in different directions, just like a mirror. A reflective sheet bounces back light from your car’s headlight or street light, creating a bright surrounding.

So, they are widely used for many occasions. Road signs and vehicle markings made from reflective sheeting do not require lighting to be visible. Reflective tapes or cloth are made for cyclists and pedestrians wearing jackets, vests, backpacks, or accessories made from reflective material to enhance their visibility to motorists.

What Is Retroreflective Sheeting?

Retroreflective sheeting is a special prismatic reflective sheet that includes retroreflective glass beads, microprisms, or encapsulated lenses, which are sealed onto a fabric or plastic substrate(PMMA, PET, or PVC sheets). Their principal also reflects light, but in a straight path. While a reflective sheet scatters light in different directions, a retroreflective sheet refocuses and returns light back to the source.

Their purpose is designed to improve nighttime visibility and safety by using them for traffic signs, reflective safety vests, and jackets.

Physics & How They Work

According to the law of reflection, light reflects off a surface at equal angles but in multiple directions. The law of reflection follows the principle that the angle of incidence is equal to the angle of reflection. Light can bounce in two different ways, depending on the smoothness or roughness of a surface.

- Specular reflection: On a smooth flat surface, light bounces away at the same angle it hit the surface. The light rays remain organized, providing a clear image.

- Diffuse reflection: When light rays hit a rough surface, they scatter in different directions, a process known as diffuse reflection. Light rays scattering prevent clear image formation, though it is still visible.

The law of retroreflection follows the rule of refraction and reflection. When a light ray hits a surface, glass beads or corner prisms reflect it to its source. Light enters the glass bead and bends (refracts) towards the center. It hits a reflective coating at the back of the bead and bends again, this time returning to its original source.

Performance & Metrics

Reflective and retroreflective sheeting are ideal for making road signals. Their performance largely differs. Reflective sheeting is a good option for creating beautiful signs that are only visible during the day. Retroreflective sheeting is ideal for safety signs that require visibility at night and during the day.

Coefficient of Retroreflection & Observation Angles

The coefficient of retroreflection (cd/lx/m²) compares how bright a material is when you shine light on it against the amount of light reflected. The brightness of a material is measured in candelas per square meter (cd/m²). The amount of light shining on a surface is measured in lux (lx).

The observation angle is the angle between incoming light and your (driver’s) line of sight. The coefficient of retroreflection ensures that the road signs are visible to drivers regardless of the observation angle.

When it comes to keeping road users safe, retroreflective sheeting outperforms reflective sheeting. Just like a mirror, reflective sheeting sends out light in different directions, which is not ideal for safety signs. Retroreflective sheeting, on the other hand, reflects light to the source, enhancing visibility.

Sheeting Grades & Intensity

Retroreflective sheeting is available in several grades with different optical properties. Each grade has a different intensity and durability. Intensity refers to the amount of light the material reflects back to the source.

- Engineer Grade (Type I): It is the most basic type of sheeting, offering the lowest visibility of about 500 feet. Glass beads and optical prisms are the primary components of engineer-grade sheeting. Its primary use is in the signs that provide information or guidance. Engineer-grade sheeting has a lifespan of around 5 years.

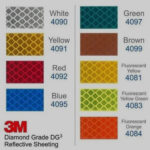

- High‑Intensity Prismatic (Type III/IV): With a lifespan of about 10 years, high-intensity prismatic has two layers. The outer layer protects against scratches, while the inner layer reflects light, making it visible 1200 feet away. A layer connecting the two has a lattice-like or honeycomb appearance.

- Diamond Grade (Type V–XI): It has a visibility of up to 1,600 feet and can last for more than 12 years. Diamond grade returns 60% of the light, and it is ideal for highway signage. Other critical signs, especially around schools or construction sites, make good use of diamond grade.

Standards & Regulations

As you choose the type of material that is ideal for the products you want, ensure that they follow proper standards and regulations.

ASTM D4956

The specifications for ASTM D4956 classify retroreflective materials into different categories (I–XI) based on type, brightness and application.

| Type | Properties |

| I | Suitable for information signs. |

| III and IV | Higher intensity for regulatory and warning signs |

| V | Enhances visibility and durability. |

| VI | Fabric for temporary signs. |

| VII-XI | Maximum brightness for highways, overhead signs, and complex intersections. |

MUTCD (Manual on Uniform Traffic Control Devices)

The MUTCD specifies the retroreflective sheeting grades to use for different applications. For example, in schools that are a high-priority area, MUCTD recommends the use of Diamond Grade sheeting. It has a high visibility rate over long distances, whether at night or in low-light conditions.

MUCTD also specifies that high-intensity prismatic is the ideal retroreflective sheeting for warning and regulatory signs. Drivers will see these signs clearly in critical areas, such as pedestrian crossings, which helps prevent accidents.

ANSI(American National Standard for High-Visibility Safety Apparel and Accessories)

ANSI/ISEA 107 classifies clothes worn by workers in a hazardous environment into three categories.

- Class 1: Low-risk areas

- Class 2: Higher traffic exposure

- Class 3: High-risk areas

Clothing that complies with ANSI/ISEA 107 should be visible during daytime, nighttime, and low-light conditions.

Real-World Applications

In the real world, reflective and retroreflective sheeting are the primary materials in making road and safety compliant signs. Because they do not require a power source to illuminate, they are ideal for making road and highway signals.

Road users also need to be visible, especially in low-light conditions, to keep them safe from moving vehicles. Wearing high-visibility clothing with retroreflective strips keeps you visible on the road, whether walking or cycling. The retroreflective strips on the clothing must be wide enough to be visible at a distance.

In most countries, large commercial vehicles, such as trailers, are required to have retroreflective material. Due to their huge sizes, they are not easily visible. The sizes and placement of the retroreflective devices must follow DOT (Department of Transportation) regulations. You can use retroreflective tape on bicycles and motorcycles.

The primary purpose of retroreflective materials in industrial or safety gear is to enhance visibility. Workwear in areas such as construction, traffic control, or emergency responders must be highly visible. A glittery finish and a beautiful look are the primary purposes of decor and crafts. Reflective sheeting is an ideal option for fashion accessories, jewelry, and craft projects.

Pros & Cons Comparison

It is crucial to understand the differences between reflective and retroreflective sheeting in order to make an informed choice. Though both enhance visibility, their physical and operational properties differ.

| Features | Reflective sheeting | Retroreflective sheeting |

| Composition | Tiny glass beads and prismatic elements. | Microscopic lenses with a honeycomb appearance. |

| Visiblity | Decreased visibility. | Offers maximum visibility, especially at night. |

| Durability | Degrades over time. | Designed for outdoor durability. |

| Applications | Helmets, traffic signs, barricades, sports, bicycles, decorations, jewelry, and crafts define hazard zones. | Safety equipment and clothing, road signs, and vehicle markings. |

| Brightness | Unless viewed from the right angle, it is dull or invisible. | It is very bright at night |

| Cost | Affordable and widely available. | It is more costly. |

Choosing the Right Sheeting

When choosing between reflective and retroreflective sheeting, consider the time of day. Retroreflective materials offer better visibility at night or in low-light conditions than reflective materials. Another factor to consider is the location from which the application will be viewed. Retroreflective is ideal if the viewer is close to the light source.

Before choosing a material, consider the application’s need for brightness and durability. Reflective sheeting is ideal for application that requires lower brightness, and durability is not a primary concern. Choose retroreflective materials for applications that require higher brightness. Consider also local regulations before choosing.

You should also consider the budget you’re working with versus the application’s performance. Choose a reflective material if working with a lower budget. However, the application will only be visible during daylight hours. Retroreflective materials are more expensive but offer visibility in all types of conditions.

FAQs

-

Can reflective be used instead of retroreflective?

No, because reflective scatters light while retroreflective directs it back to the source. Hence, a retroreflective material is more visible when you stand near a light source.

-

Difference between glass beads and prismatic retroreflectors?

Glass beads use microscopic glass spheres to reflect 30% of the light. However, they are more affordable, cuttable, and return light at wider angles. Prismatic retroreflectors return 80% of the light back, using man-made prisms. Hence, they are more efficient and ideal for long-distance viewing.

-

What grade is needed for road signs?

High-intensity prismatic sheeting is ideal for critical road signs, especially warning or speed limit signs on public roads. You can also use reflective sheeting for off-road signs on private properties.

-

How long does retro sheeting last outdoors?

Retro sheet durability will depend on the type and environmental conditions. However, high-quality retro sheets have a lifespan of 12 years or more.

Conclusion

Choosing between reflective and retroreflective will primarily depend on the type of application. Reflective is ideal for those applications that can work with low visibility, while retroreflective is for those that require high visibility.

At Jackwin, we provide high-quality road signs that follow DOT and MUTCD standards. Contact us for all types of road and traffic signs.

-80x69.png)