Supply and Wholesale All Types of Road Barriers

JACKWIN has been a professional manufacturer and supplier of road barriers for over 15 years. We are committed to providing various types of road barriers for overseas customers. If you intend to buy road barriers, please contact us to get an updated quote, we will ensure the supply of premium road barriers at low factory prices.

What Are Road Barriers

Road safety barriers are objects that are mainly used for road construction isolation, restraining and limiting the direction of vehicle travel, and protecting the safety of drivers, workers, and pedestrians. Road safety barriers are divided into different functions, materials, sizes, colors, and shapes for sale.

Road Barriers By Type

JACKWIN offers all types of road barriers in different types, applications, materials, and sizes. Browse the below road barriers for sale, and click to get a fast quote to estimate the cost for your project or bids.

Metal Road Barriers

Highway guardrail, Q235 or Q345 hot dipped galvanized steel

Size 2000x1000mm, rubber base, portable for barricade lights

Maxpand 3500mm, interlock link, wheels with brake

Size 2000x1000mm, central plate for customization logo

Road Barrier By Material

JACKWIN offers premium quality materials for road barriers, browse below to get a fast quote now!

-

JW-RB-020 Wire Rope Road Barrier

JW-RB-020 Wire Rope Road BarrierWire rope safety barrier systems, custom post height and wire cable diameter

-

JW-RB-021 Road Noise Barriers

JW-RB-021 Road Noise BarriersUsed for highways, railways, and urban transit routes

-

JW-RB-022 Rolling Road Barriers

JW-RB-022 Rolling Road BarriersEVA material, designed for highway guardrail roller barrier

-

JW-RB-010E Mobile Road Barriers

JW-RB-010E Mobile Road BarriersExpandable, adjust gate, steel barricade, max expand 3.5 meters, powder coated

Feature box

To learn more product details, please browse JACKWIN road barrier advantages and features as follows.

made of durable HDPE material and rotational mold processing.

suitable for different working scenarios and applications.

made of plastic material, low cost and high-cost performance.

good buffering and anti-collision effect, safe and reliable.

yellow and red color with reflective stripes.

degradable plastic, environmentally friendly and safe

interlock design, quick and easy installation.

in compliance with American MUTCD standards and European BS EN13422 standards.

Customize Your Road Barriers

JACKWIN provides customization of all shapes, sizes, and materials for your road barriers to boost your business.

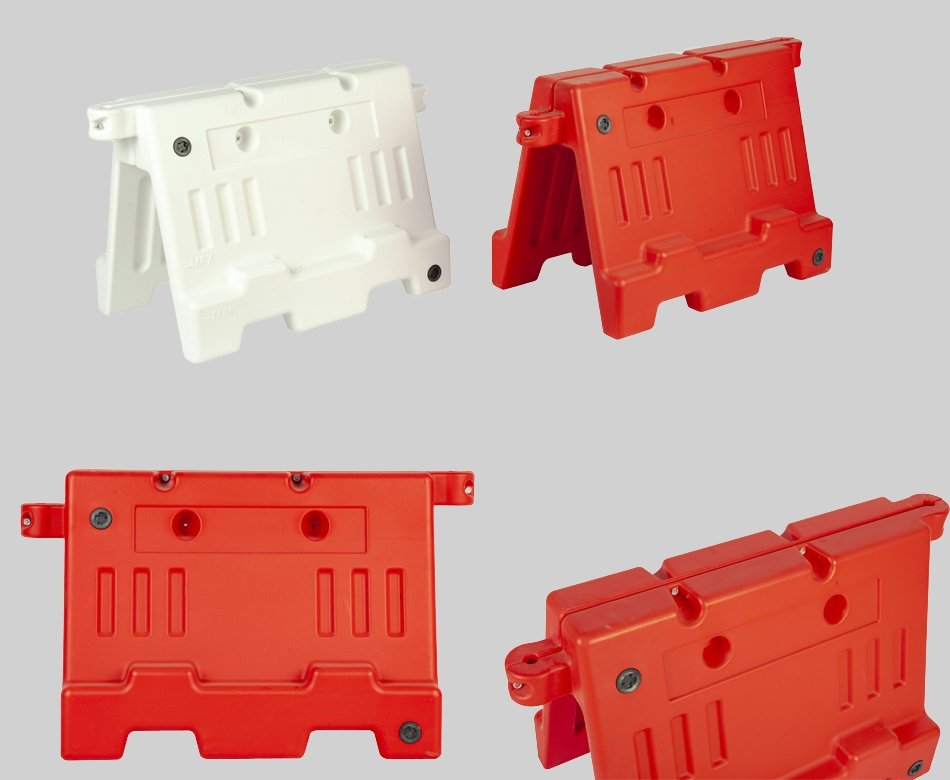

Water-filled Road Barriers

JACKWIN water-filled road barriers are made of impact HDPE material by rotational or blow-molded processing. It can be filled with water or sand to strengthen the weight and stability. Our HDPE plastic materials are high quality with UV resistance, good toughness, impact resistance, anti-aging, long service life, and are resistant to wind and rain. Bright yellow and red colors are not easy to fade.

Metal Road Barriers(crowd control barrier)

JACKWIN crowd control barriers are welded by heavy-duty steel pipes with powder coating surface or smooth galvanized surface. They are designed with secure interlocking hooks to connect one by one.

Water-filled Lane Divider

Made of durable polyethylene material, our diversion indicator can be filled with sand and water, which is perfect for highway exits, tollbooths and lane divisions. Our road barrier with reflective arrows ensure high visibility at night. JACKWIN lane divider size: 1500X800X1350mm, customizable minimum weight: 25kg.

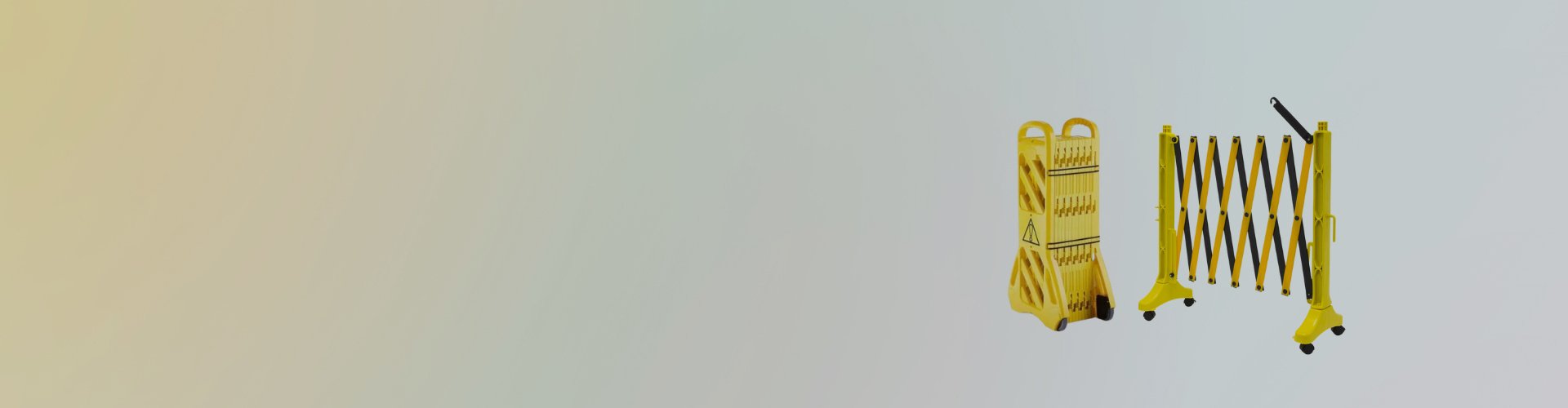

Expandable Barriers

Our expandable barriers are manufactured by injection or blowing molded processing, and they are flexible and easy to install. Lightweight designs are easy to carry and move.

Temporary Road Barriers

JACKWIN barriers are designed for temporary use in road safety projects. They can be made of steel or plastic. It can be a fence panel or plastic barrier, but no matter which one it is, its purpose is to secure construction sites, to manage crowd control and security at outdoor events.

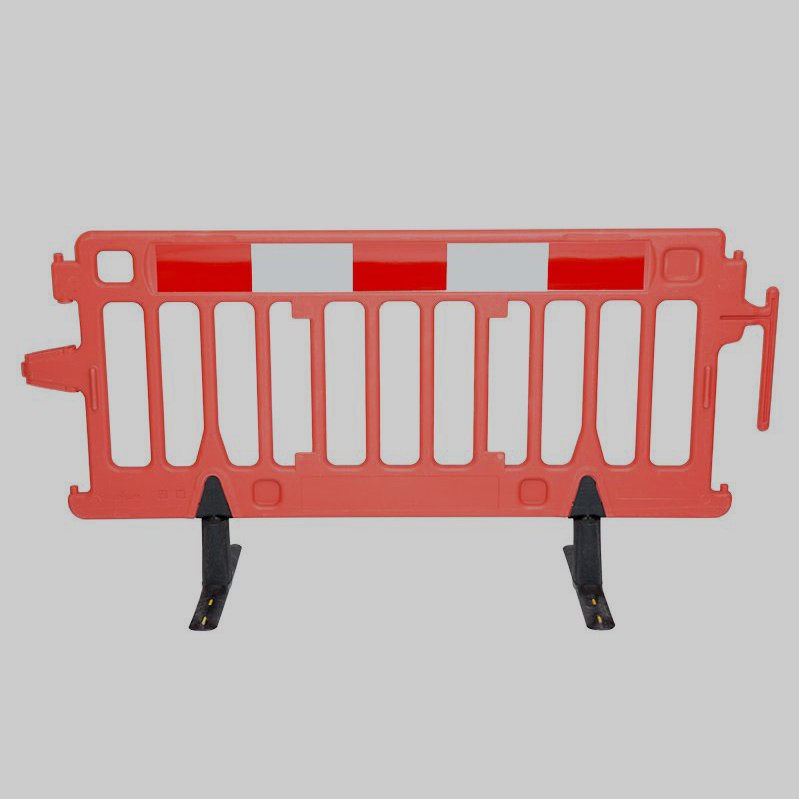

Plastic Road Barriers

We have bright yellow, orange, red, or white colors available. Type 1, Type 2, and Type 3 road barricades are included in the types of plastic road barriers, the material of the frame and panel is ABS with orange reflective to enhance visibility.

JACKWIN Germany Road Safety Barrier

- UV-resistant, impact-resistant plastic material.

- The standard color is white or grey.

- Reflective film grade RA1, weight 14 KG.

- 360-degree rotatable feature panel fence.

- Length: 2 to 2.15 meters, height: 1 to 1.10 meters.

- Vertical pipe extending full length from top to bottom provides extra stability.

- Multiple panel fences can be connected using the connector on each fence.

- The advertising area is an extra option.

Resource

Blowing Molded Plastic Road Barrier

JACKWIN production of road barriers adopts hollow blow molding, which has the advantages of high production efficiency, low cost and short delivery time. It is suitable for large-quantity order production and is more cost-effective and efficient than rotational molding road barriers. It takes 35 days from drawing design and confirmation to mold making for blow molding mold. Therefore, the general development cycle of new products takes at least 35 days.

Applications

JACKWIN road barriers are widely used for various occasions and play an importable role in the safety industry.

as road traffic safety is an essential part of our daily life, heavy-duty road barriers are the top consideration, using plastic water-filled road safety barriers will ensure high visibility and stable weight on the road to reduce accident rate.

portable road barriers in plastic and steel are both available for road construction, they are an easy-to-move and linkable option so are perfect for temporary or short-term work zones.

used for highway or street road work, during the maintenance period, provide safety protection for construction workers, passing vehicles and pedestrians to prevent strangers from mistakenly entering the construction area or causing accidents.

also called collapsible road barriers for private roads or residential roads, factory workshops, or warehouses. Universal casters for easier mobility.

made of hot-dip galvanized steel, absorbs the impact and prevents vehicles from veering off the road, commonly used for highways or roadways.

high visible yellow and black color, prevent pedestrians from climbing over guardrails and causing traffic accidents.

Workshop and Production

Learn more JACKWIN workshop and production line, you will get to know more knowledge about road barriers.

JACKWIN some parts of road barriers are produced by rotational mold machines.

Blow molded machine in JACKWIN produces water-filled road barriers.

More Details of Road Barrier

View more specifications for JACKWIN road barriers as follows.

- Data Sheet

Water-filled Plastic Road Barriers

| Material | Length/mm | Top Width/mm | Bottom Width/mm | Height/mm | Weight |

| HDPE | 1300 | 180 | 370 | 650 | 8.5 kgs |

| HDPE | 1650 | 150 | 410 | 650 | 9.0 kgs |

| HDPE | 1400 | 145 | 400 | 800 | 7.5 kgs |

| HDPE | 1500 | 180 | 370 | 800 | 9.5 kgs |

| HDPE | 2000 | 145 | 400 | 800 | 19 kgs |

| HDPE | 1200 | 80 | 260 | 600 | 6.0 kgs |

| HDPE | 1500 | 150 | 430 | 1200 | 14 kgs |

Metal Barriers on Roads

| Material | Length/mm | Height/mm | Processing |

| Iron tube | 1200 | 1000 | galvanized or powder coating |

| Iron tube | 1500 | 1000 | galvanized or powder coating |

| Iron tube | 1800 | 1000 | galvanized or powder coating |

| Iron tube | 2000 | 1000 | galvanized or powder coating |

Expandable Road Barriers

| Material | Processing | Size | Max Length | Weight |

| HDPE | Blowing | 940x340mm | 2500mm | 2.2 kgs |

| HDPE | Blowing | 1080(H)x470(W)x150(D)mm | 2200mm | 6.8 kgs |

| PVC | Injection | 1000(H)x300(W)mm | 3900mm | 15 kgs |

| PVC | Injection | 950(H)x420(W)x420(D)mm | 3500mm | 7 kgs |

| Steel | Welding and powder coating | 960(H)x390(W)mm | 390 to 3300mm | 17.5 kgs |

Plastic Road Barriers

| Material | Length/mm | Height/mm | Width/mm | Weight |

| HDPE | 2280 | 1200 | 65 | 15 kgs |

| HDPE | 1950 | 1000 | 55 | 11.5 kgs |

| HDPE | 2000 | 1000 | 400mm(foot) | 12 kgs |

Testimonials

Normally, our MOQ is 250 to 500 pcs, depending on the model, we suggest FCL (full container load) for the barriers, as they are big and loaded directly in containers, which will reduce damage during transport and ensure they will arrive in good condition.

Our production time will be around 15 days for the barriers, if you place a large quantity, we will check the exact lead time and provide a partial shipment plan.

Yes, depending on your quantities, we will accept customized barriers on your drawing or specification, new mold will be produced and the charges should be covered by us or paid by your side.

Related Product

Road Barrier Colors

JACKWIN supplies road barriers colors in orange, red, yellow, white, green and black. And also we customize in blue, lilac, grey, or any other colors.

A-Frame Barricades

JACKWIN A-frame barricades are mainly used in construction, traffic safety, and crowd control in the United States. There are several types of barricades, type 1, 2, and 3. No matter what type, each full set includes legs and I-beam boards. The materials are metal and plastic for you to choose at competitive prices.

Concrete vs. Plastic: Which Barrier Material Works Best for You

Construction supervisors often debate the merits of concrete versus plastic road cones and barriers. Each material has distinct advantages depending on specific project requirements.

Concrete Barriers: The Heavy-Duty Option

Concrete road barriers are what most people think of when they hear ‘road barrier’. Their best use case is for prolonged protection in high-risk environments. Once placed, these road barriers types don’t need much maintenance. Plus, they are able to withstand repeated impacts without incurring severe degradation. Because of their weight, they form a solid barrier between workers and traffic.

Plastic Barriers: The Flexible Alternative

Today’s plastic barriers have vastly improved from the flimsy progenitors. JACKWIN’s SM-004 Jersey Barricades are made using good-quality HDPE material, which makes them very strong and resistant to all types of conditions. Some designs come with an interlocking mechanism and a water-ballast chamber which, when deployed, would provide a staggering degree of support.

Plastic barriers shine when:

- Projects require frequent reconfiguration

- Work zones change shape or location regularly

- Installation must occur with minimal disruption to traffic flow

- Transportation resources are limited

The most effective worksites often employ both types strategically—concrete barriers for fixed perimeters and plastic for areas requiring frequent adjustment.

Why Choosing the Right Road Barriers Could Save Lives

A barrier’s job is to redirect, slow down, or stop an out-of-control vehicle. The wrong choice can make that job impossible.

Take a common mistake: using a lightweight plastic barrier on a high-speed roadway without proper ballasting. A pickup truck veering off the lane at 65 mph won’t even slow down as it crushes through it. Now contrast that with a properly installed concrete jersey barrier—anchored, interlocked, and certified for redirective impact. That same vehicle may still hit the barrier, but the outcome for the crew on the other side is vastly different.

Water-filled road barriers provide flexibility for shorter-duration projects. While less robust than concrete, they absorb impact forces differently—their give can actually reduce injury severity in certain collision scenarios. The trade-off comes with higher maintenance needs and vulnerability to tampering.

Steel barriers like the JW-RB-018 by JACKWIN offer excellent strength-to-weight ratios and quick installation, making them ideal for overnight work or emergency repairs. Their narrower profile preserves more roadway width in confined spaces, though their purchase cost exceeds other options.

Concrete road barriers, though heavy and logistically challenging, shine in long-term projects and high-speed zones. They absorb and redirect energy better than most other types. But even within these categories, there are distinctions—TL-1 through TL-5 crash ratings, anchoring requirements, and connector systems all influence effectiveness.

It’s not just about what fits the budget or is available at the yard. It’s about risk, location, and the real-world behavior of vehicles and drivers under stress.

How Far Apart Should Your Road Barriers Be?

Barrier spacing is one of the most frequently misunderstood aspects of proper installation. Contrary to popular belief, there is no universal “correct” distance between barriers. Instead, spacing depends on a complex interplay of factors.

Most jurisdictions dictate the maximum allowable gaps based on the speed limit for the project.

| Speed limit | Maximum Distance Between Barriers |

| 25-35 mph zones | 6 feet |

| 35-45 mph zones | 4 feet |

| 45+ mph zones | 2-3 feet |

The Most Efficient Removal and Relocation Methods

Removing and relocating barriers safely requires as much planning as initial installation. Many workplace incidents occur during this phase when teams rush to clear sites.

For concrete barriers:

- Establish clear lifting points before removal begins

- Use appropriately rated chains and lifting equipment

- Ensure spotters maintain visual contact with operators during lifting

- Create designated staging areas for removed barriers

For water-filled road barriers:

- Plan drainage paths that won’t create hazards or environmental issues

- Allow sufficient drainage time before attempting to move barriers

- Consider specialized evacuation pumps for rapid relocation

When relocating barriers within the same project, develop a clear sequence that maintains protection for workers throughout the transition. Temporary road barriers may be necessary during these intermediate phases.

-80x69.png)