Abrasion Tester for Sale

JACKWIN offers a comprehensive range of abrasion testing machines for road contractors, wholesalers, road transportation department and road maintenance staff. Our products include taber abrasion tester, linear abrasion testers and din abrasion testers. By using taber abrasion tester, you can evaluate the durability of road marking paint to reduce traffic accidents caused by faded road marking lines.

What are the types of abrasion testers?

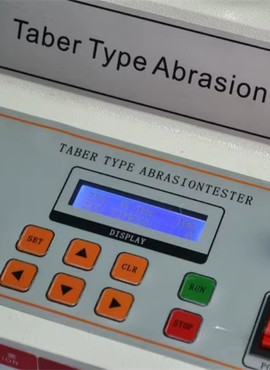

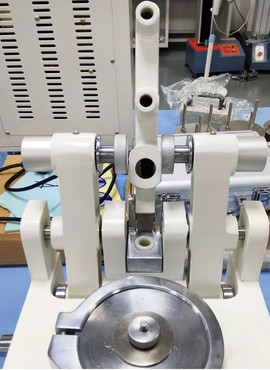

Rotary Abrasion Tester: Taber abraser is a representative of rotary abrasion tester, which simulates real-life wear conditions by pressing two abrasive wheels against the rotating specimen surface with specific load. Rotary abrasion testers are commonly used for road marking materials, plastic, coating, wood and metal.

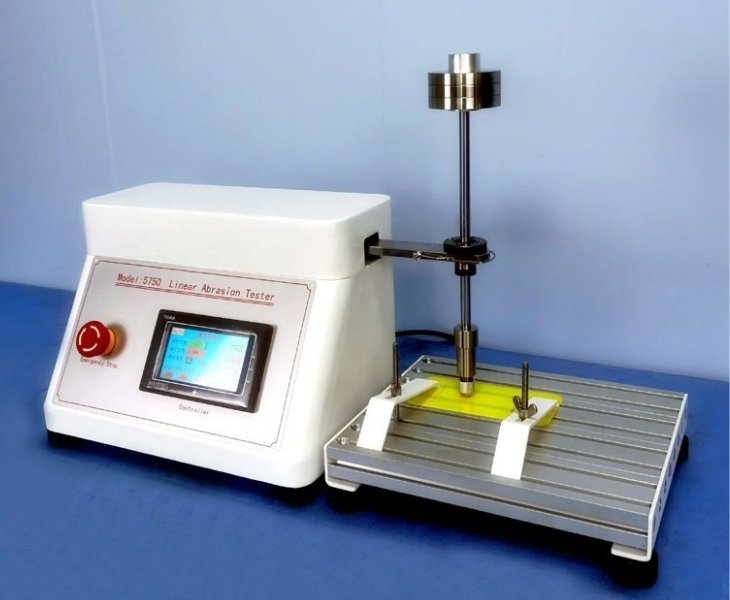

Linear Abrasion Tester: designed to simulate linear rubbing movement by moving the abrasive head across the specimen back and forth. It fits for paint, coating, road marking samples, plastic housing and flooring.

DIN Abrader: simulate the real-world wear of rubber products by pressing rubber specimen against rotating abrasive sheets. DIN abrader is widely used for tires, rubber traffic cones, rubber speed bumps and rubber base weights.

Martindale Abrasion Tester: an instrument to measure the abrasion of fabric, coating, leather or flooring. It uses Lissajous motion(a figure-eight pattern) to simulate the wear and pilling of textile.

Ink Rub Tester: used to measure the durability of printed surfaces such as paper, labels and packaging.

Sand Abrasion Tester: also named sandblast abrasion tester, used to evaluate the erosion and wear of sand or other particles on the surface of an object. It fits for paint, varnish and lacquer.

Abrasion Resistance Tester by Types

JACKWIN provides various abrasion resistance testers, including taber abraser, linear abrasion tester for road markings paint.

Changeable two 250g/500g/1000g weights each, rotary abrasive wheels, precise cycle counter with vacuum cleaner.

Electronic display, AC 220V 50HZ, for road marking paint, specimen size: outer dia.100mm X inner dia.8mm X thickness 3mm.

3 pcs 250g disc weights, 0.5/1/2/3/4 and customizable moving distance, adjustable moving speed and rotation number.

220V 50Hz, 40±1rpm wheel speed, 10±0.2N specimen load, for rubber traffic cones, rubber speed bump and rubber related products.

JACKWIN Rotary Abrasion Tester

JACKWIN offers abrasion testers to quickly evaluate the durability and reliability of road marking paint. Our abrasion tester is the primary tool for testing the abrasion resistance of road markings. Pour the thermoplastic road marking paint into a cake-shaped sample, and place it in the machine to measure the paint’s abrasion resistance.

- Adjustable 250g/500g/1000g different load weights, simulate the wear resistance of samples under different loads.

- 60/70 rpm or specified rotating disk speed for options.

- LCD digital display, 1-999999 spins with auto-stop.

JACKWIN abrasion resistance tester has 1-year warranty and is widely used for laboratories to evaluate the wear resistance of road marking lines in crosswalk, highways and airport runways.

JACKWIN Linear Abrasion Tester

JACKWIN linear abrasion testing equipment is suitable for testing the wear performance of paint, coating, printing products, textiles and plastics. Featuring touchable screen, 3pcs 250g disc weights, adjustable moving distances and speed, JACKWIN linear abrasion tester has 1-year warranty and step-by-step instructions. If you are looking for abrasion tester that performs linear reciprocating motion, our linear wear testing machine can be your first choice.

How to Use Abrasion Tester for Road Markings?

JACKWIN abrasion testing machine can help to measure the performance of road marking lines under different loads. The following are the steps to use an abrasion tester to measure wear resistance:

- Sample Preparation: pour the melted thermoplastic road marking paint into a round-shaped mold and wait for its cooling.

- Record the initial weight of the road marking cake sample in advance and install the sample on our instrument.

- Select a suitable grinding wheel and mount it to the wear arm. Typically a rubber grinding wheel is used to simulate tire wear on road markings.

- Add a load of 250g/500g/1000g to the abrading arms.

- Set the desired total number of revolutions on the instrument(usually at least 100-1000 revolutions) and start the vacuum cleaner.

- Start the instrument and clean the dust and grinding debris from the sample after the instrument is finished. Record the sample weight after the test.

- Analyze the test results and evaluate the wear resistance of the tested road marking paint.

Ресурсы

Хотите узнать больше о характеристиках продукции? Просто просмотрите и скачайте каталог JACKWIN, перейдя по ссылке.

Хотите узнать больше о продукции и компании JACKWIN? Просто нажмите на ссылку на видео, и вы получите больше, чем думаете.

Taber Abrasion Tester v.s. Martindale Abrasion Tester

Taber Abrasion Tester

Motion: rotary griding

Applied Stress: use heavier weights (250g/500g/1000g) to apply pressure to the sample

Main Measured Result: mass loss (mg), compare the difference in mass before and after the test

Приложение: road markings, paint, coating, plastic, composites, wood and metal

Martindale Abrasion Tester

Motion: multidirectional Lissajous motion (figure-8 pattern)

Applied Stress: mainly simulates rubbing action with low pressure (9kpa/12kpa)

Main Measured Result: visual change. Observe the degree of fabric pilling, fuzzing and thread breakage

Приложение: textiles, carpets, apparel, leather and gloves

Taber type abrasion tester is more suitable for testing wear resistance of hard material while Martindale abrasion tester is for soft fabric material. If you are looking for an abraser to evaluate the performance of road markings, JACKWIN offers you taber abrasion tester with reliable quality and affordable wholesale price.

Abrasion Tester Applications

JACKWIN abrasion tester have diverse applications across various industries, such as road markings, traffic cones, coating, paint, metal and plastic.

Our JACKWIN abrasion tester can be used to test the abrasion resistance of thermoplastic road markings, ensuring road safety.

Commonly used for automotive paints, wood floor varnishes, pipe coatings, and industrial equipment coatings.

Tests the abrasion resistance of various plastics for applications such as remote controls, keyboards, traffic signs, and plastic traffic cones.

Use the JACKWIN abrasion tester to test wear resistance of stainless steel, galvanized steel, alloy steel, door and window frames, and other metal products.

Simulates the wear and tear caused by everyday friction on glass, such as windows, mobile phone screens, and car windshields.

Подробнее о нашей компании

JACKWIN offers a comprehensive range of road safety products including дорожные конусы, дорожные знаки, лежачие полицейские, машины для дорожной разметки и краска для дорожной разметки. We have more than 18 years experience and our products have been exported to over 50 countries. Equipped with advanced machinery and professional technicians, our products are reliable in quality. Связаться с нами чтобы получить больше информации.

- Техническая спецификация

- Послепродажное обслуживание

- Галерея

| Specimen Size | 120X6.5X3mm |

| Load | 250g/500g/1000g |

| Testing Disk Speed | 0-70 rpm adjustable |

| Machine Demensions | 30X43X30cm |

| Machine Weight | 30 кг |

| Аксессуары | a wrench, a group of grinding wheel, weights(250g/500g/750g)each two pcs, vacuum cleaner |

| Источник питания | AC 220V 50Hz |

All JACKWIN abrasion tester have a 1-year warranty. We provide comprehensive after-sales service. If you encounter any technical or quality problems during use, we will provide one-on-one guidance and solutions.

JACKWIN abrasion tester is used to evaluate material’s wear resistance. It simulates the testing materials’ wear and tear because of rubbing in the real world, which can get quick measured results in a short time.

The principle of a wear tester is to apply a certain pressure to the surface of a material, causing friction and scratches during the mutual movement. The resulting wear is measured to evaluate the material’s wear resistance.

The abrasion tester is used to evaluate the performance of material and verify whether the product meets the durability standard. It is widely used for most kinds of materials, including coating, paint, plastic, metal, rubber and textiles.

-80x69.png)