Wholesale Rubber Base Weights for Sale

JACKWIN offers different sizes and weights of rubber bases for your delineators posts, vertical panels, sign plates, footpath & display signs, and stands for base weight purposes in various applications.

Rubber Base Weights Basic

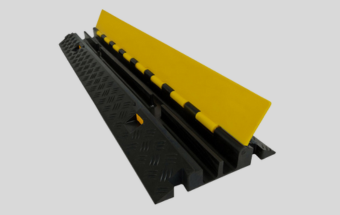

Rubber base weights are also known as base weights, rubber-weighted sign bases, footpath sign bases, and vertical panel bases. They are intended to increase weight and stability for your vertical panel, footpath sign, T-top bollard, pipe, and drape. Rubber weight bases are widely used in North America, Europe, Australia, New Zealand, the Middle East, and South Africa.

Rubber Base Weight By Features

JACKWIN offers all various rubber base weights, when you are equipped with vertical panels for traffic management, install the display ACM panel sign, pipe and drape, and traffic delineator, our rubber base weight is an essential part of your material.

Rubber Base Weight

Size 800x400x120mm, 15 and 17kg for option, designed for foot of traffic vertical panel, parking sign, delineator,bollard fence,and barrier

Size 570x460x57mm, 12kg, designed for parking sign panel, traffic bollard, and footpath sign, made of recyclced rubber material

Size 575x460x57mm, 12kg, custom your debossed logo, used for display sign board and traffic panel in Australia and New Zealand

Designed to fit AU & NZ rubber base, made of ACM sheets, thickness 3 to 6mm for your display and footpath sign panel, custom graphic.

Optional 20lbs & 30lbs, size 450x450x51mm(18″x18″x2″), designed for drape and pipe fittings, made of recycled rubber material

Size 18×18 inches, designed for rubber base weight of uprights drape & pipe, used for your backdrops, trade shows, events, photo booths & decorations

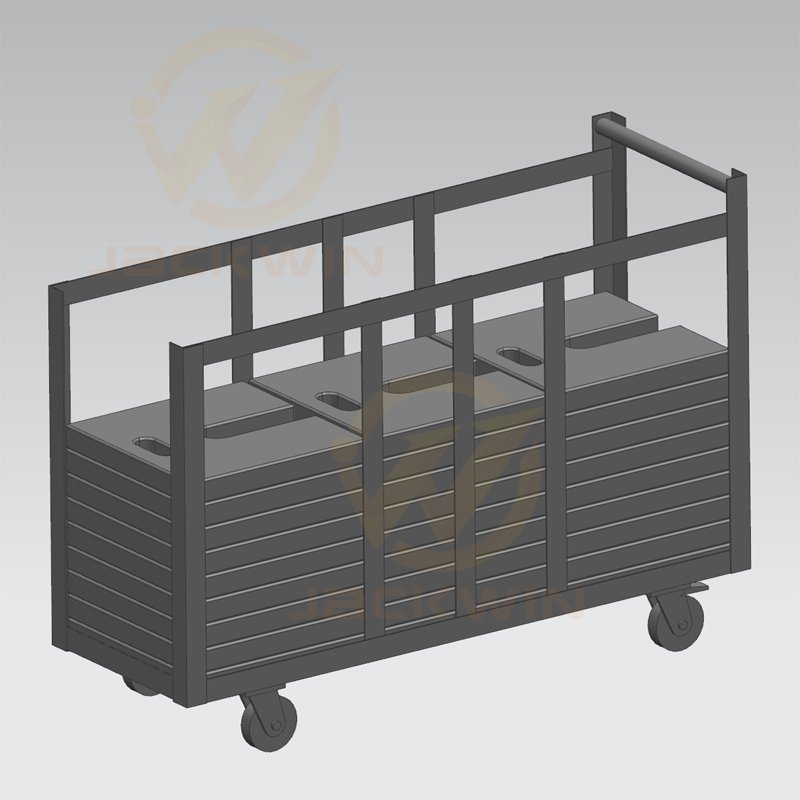

Made of solid steel and designed for drape and pipe rubber base weight, multi-directional casters with brakes, can load 35 Ea bases

Size 425x325x85mm, 10kg, heavy-duty weight, designed for traffic panel and chevron delineator blade

Made of recycled rubber material, used for blade in Australia, and New Zealand market, with grip-handle

Optional 6 & 8kg, fit for t-top delineator post, debossed logo for your customization, grip-handle easy to carry and carting

Made of recycled rubber material, fit for traffic panel and parking sign, customize your debossed logo to reach quantity of 1000 pcs

Designed for warning board and display panel to increase stability and holder, with a grip-handle easy to carry and install

Pipe and Drape Rubber Base Weight Shipment

At JACKWIN, we consistently share videos and images of our rubber base weight production progress, packaging, and shipping. We maintain constant vigilance over production quality control, giving you the same peace of mind as if you were visiting our factory in person.

-

20 LBS Rubber Base Weight

20 LBS Rubber Base Weight20 LBS rubber base weight packed by cart for loading container, cart with wheels are customized.

-

20 LBS Rubber Base Weight Loading

20 LBS Rubber Base Weight Loading20 LBS rubber base weight fully loading the container.

-

-

30 LBS Rubber Bases Container Loading

30 LBS Rubber Bases Container LoadingIn the summer, workers were drenched in sweat to load our customers’ bases.

-

20 LBS Rubber Base Weight In Cart

20 LBS Rubber Base Weight In CartYou can choose our cart to package and load into your container, it’s convenient for your storage and move.

-

Rubber Base Weight Packed by Carton

Rubber Base Weight Packed by CartonYou can customize boxes with your private label and then palletize them for container loading.

-

Rubber Base Weight LCL Shipping

Rubber Base Weight LCL ShippingWe shipped your small QTY of rubber base via truck to freight forwarder’s warehouse for container consolidation(by LCL).

Rubber Base Weights

JACKWIN’s rubber base weights are made of 100% new rubber material that can resist heavy-duty weight and is durable. The main features are as follows:

increases stability and withstands wind.

recycled rubber material, aging-resistant, wear-resistant, UV-resistant, not corroded.

stackable for easy shipping and transportation.

strong impact resistance, not be damaged easily.

suitable for use outdoors.

not need maintenance and is cost-effective.

non-conductive, more safer.

with a grip handle to carry it.

Design Your Rubber Base Weights

JACKWIN can assist to design your artwork of display panel on both sides, also we can print the film or tape on panel by digital or solid silk screen printing.

Rubber Base Compliant to REACH Standard

Compliant to REACH and RoHS certification, JACKWIN rubber base weights are free from any pungent smell. The common rubber base weight smells bad because of the off-gassing of VOCs, immature vulcanization process and the use of chemical additives.

Why are JACKWIN rubber base weights virtually odorless?

- JACKWIN uses premium rubber material, plasticizers, and fillers with low odor to replace pungent synthetic rubber and raw materials.

- By improving the vulcanization process. Our factory uses low-odor vulcanizers and strictly controls the vulcanization temperature and time, preventing rubber products from over-reacting and producing more volatile organic compounds.

- Our researchers have found that adding deodorizers and odor neutralizers can effectively reduce odors.

- JACKWIN avoids the overuse of stabilizers such as plasticizers, accelerators, and stabilizers.

Vertical Panel Rubber Base Weights

This type of JACKWIN rubber base weight is equipped with a traffic vertical panel to indicate driving directions during temporary traffic control projects or parking lots. It is popular in Europe, the Middle East, and Africa.

Footpath Sign Rubber Base Weights

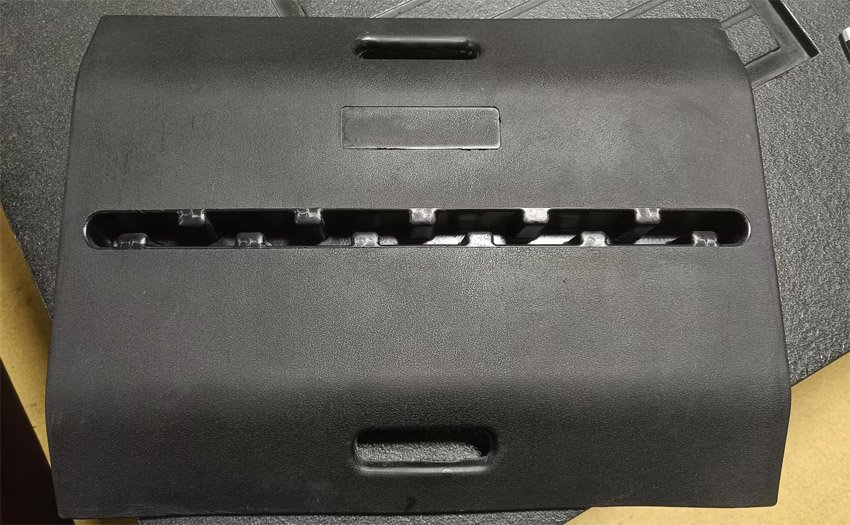

JACKWIN rubber base weight is also used for footpaths and display signs in New Zealand and Australia. The sign is made from an ACM panel of 4 to 6mm thickness and inserted into the slot of rubber base weight. Our base weight is 12 kg and enough weight to hold the sign in good condition.

Pipe and Drape Base Weights

This JACKWIN rubber base weight increases stability for pipe and drape. The horseshoe design is easy to slide on top of the base with two slots: 2.5 and 3 inches. 20 lbs and 30 lbs weights for your options. They are perfect for adding additional weight for pipe and drape backdrops, umbrellas, pop-up tents, pipe and drape tents, trade show tents, and temporary parking sign poles. The main market is in the USA and Canada.

Chevron Delineator Blade Rubber Base Weights

This type of JACKWIN rubber base weight is usually equipped with reflective delineator blades to manage and direct traffic in temporary work zones, especially in construction zones or on roadways. They are widely used in Australia and South Africa.

T-Top & Stackable Bollard Rubber Base Weights

This type of JACKWIN rubber base weight is usually equipped with T-top bollards or stackable bollards for traffic delineators. Two different weights, 6 kg and 8 kg, are available. They are generally used in the Australian and New Zealand markets.

Resources

For more details about our rubber base weights, please click to download JACKWIN catalogue.

You can visit our youtube gallary to know more about our rubber base weights and JACKWIN company.

To learn more about JACKWIN products, please follow our knowledge center.

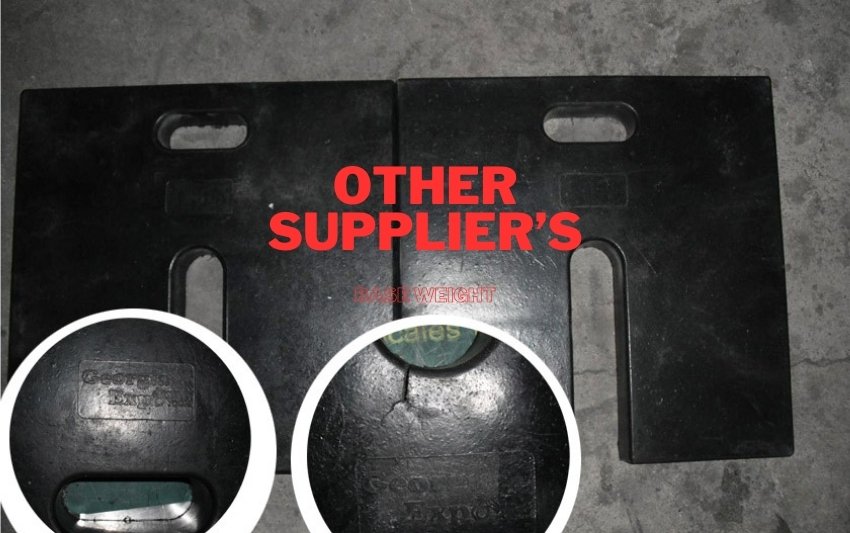

JACKWIN Rubber Base Weight VS Other Suppliers’

Judging criteria: The quality of the rubber base depends on its corners and surface. If the corners and surface are full and smooth, and there is no lack of rubber material, it means that the quality of the rubber base is very good.

JACKWIN rubber base production temperature is 122℃, while other suppliers have a temperature of 150-170℃. Our temperature is low, which makes our production time longer. We are sacrificing efficiency (increasing costs) to improve our base quality. Other suppliers have high temperatures, short production time, and high efficiency, which causes some quality problems such as lack of rubber material or cracking at the base corners.

Secondly, we supplement rubber materials twice in the production process to fill the possible lack of rubber material at the corners. Other suppliers are one-time addition of materials for vulcanization molding.

Obviously, the quality of our rubber base exceeds that of peer suppliers.

Rubber Base Weight Applications

JACKWIN’s rubber base weights are used in many situations and applications, mainly as auxiliary accessories to increase the stability of the product.

Mainly fit for delineator post, traffic panel which used in contruction site.

Delineators, and traffic board base in work zones to increase the stability.

Mainly fit for parking panel sign and insert into slot of base to stand.

Used to support the stage barriers foot, temporary tents for base weight.

JACKWIN Rubber Base Weight Production

The production of rubber base weight mainly includes the steps of material mixing, crushing, rolling, slicing, weighing, and vulcanization.

The vulcanization of rubber is the most critical production process. The quality of the rubber base weight depends on the temperature and time of vulcanization molding.

This is rubber material in sheets, raw rubber after mixing, crushing, and refining. It is a semi-finished raw material used to produce rubber base weight.

This is the finished rubber base weight for display and footpath sign, the surface is a litchi texture design, very high-quality texture, deeply loved by customers. We can accept customized customer logos by making a small inlay debossed mold if your order quantity reaches 800 EA.

All our rubber bases are packed in pallets, secured with protective film, corner protector and packing tape, and then loaded and unloaded in containers using forklifts in a standardized manner.

More About Rubber Base Weights

There are many uses, types and sizes of rubber base weight. You can learn more about the sizes, specifications and weights below. If you need to discuss with us in depth, please feel free to contact us.

- Specifications

- Installation

- Standard and Certification

| Item Number | Material | Size | Weight | Slot Width |

| JW-RB-01 | Rubber | 80x40x12cm | 15kgs | 60x60mm and 45x45mm |

| JW-RB-02 | Rubber | 61x46x57cm | 11kgs | 3“ |

| JW-RB-03 | Rubber | 18″ x 18″ x 2″ | 20lbs or 30lbs | 2.5” or 3″ |

| JW-RB-04 | Rubber | 42.5×32.5*8.5cm | 10kg | 8mm |

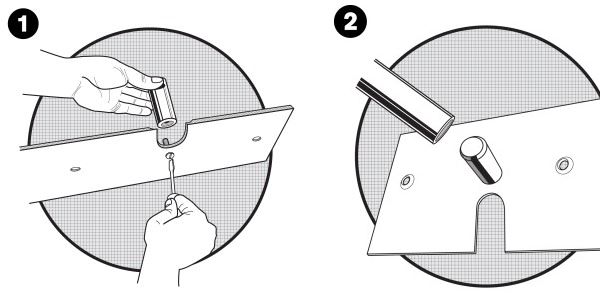

How to Install JACKWIN Base Plate (Slip-Fit Base)?

First, insert the pin into the steel plate hole, then put your Upright tube and align it with the pin.

Finally, tighten the screws and align the rubber base weight with the plate.

To learn more details, please view the installation step-by-step guide.

As requested by JACKWIN clients, our rubber material supplier tested and SVHC screening is performed according to:

(i) Two hundred and thirty-three (233) substances in the Candidate List of

Substances of Very High Concern (SVHC) for authorization published by

European Chemicals Agency (ECHA) on and before Jan 17,2023 regarding

Regulation (EC) No 1907/2006 concerning the REACH.

Also, our supplier submitted sample of rubber and SGS gave the result based on our submitted sample(s), the results of Lead,

Mercury, Cadmium, Hexavalent chromium, Polybrominated biphenyls (PBBs),

Polybrominated diphenyl ethers (PBDEs) comply with the limits as set by RoHS

Directive2011/65/EUAnnexII; recasting2002/95/EC.

Customers' Reviews

We can provide a free sample, but the shipping cost should be taken by your side.

Our regular production time is approx 20 days for a full container.

All of our rubber base weights will be packed by pallet.

Related Product

Effect of Melt Vulcanization Temperature on the Production Quality of Rubber Base Weights

The most suitable vulcanization temperature for rubber base weight production is 122℃, the experience summarized by JACKWIN from more than 15 years of the production process.

The higher the temperature (for example, more than 122℃), the faster the melting time of rubber, but as the entire production time is shortened, the middle part of the rubber block is not fully melted, and the rubber material in the corners is not filled. After one-time vulcanization, the surface of the rubber base weight is not smooth enough or the corners are lacking glue, cracking and other quality problems.

Therefore, the vulcanization temperature plays a key role in the production of rubber base weight. If it exceeds the standard temperature of 122℃, the quality of the product will be greatly affected. Usually, many suppliers vulcanize at a temperature of 150℃ or even 170℃. The advantage of this is to accelerate the vulcanization time, improve production efficiency, reduce costs, and thus sacrifice product quality.

-80x69.png)