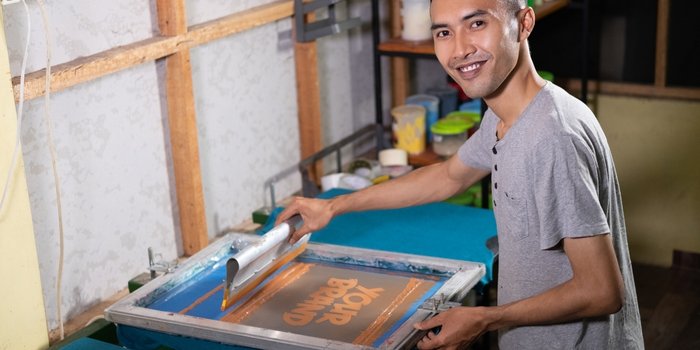

As you already know, printing on different products is a powerful way to share your ideas and designs. Among the many methods in the printing industry, silk screen printing is the most popular technique due to its clarity and lasting impact.

This simple guide will show you what silk screen printing is, its working, required materials and screen printing benefits.

What is Screen Printing?

Silk screen printing is an ancient technique used to print designs on different materials. To create an image, you can push printing ink through a fine mesh screen. The screen works like a stencil and allows ink to pass only where the design is open (tiny holes in the screen).

You can use this method on fabric, paper, glass and metal. It is a popular method in many industries because it makes bold, bright and long-lasting prints.

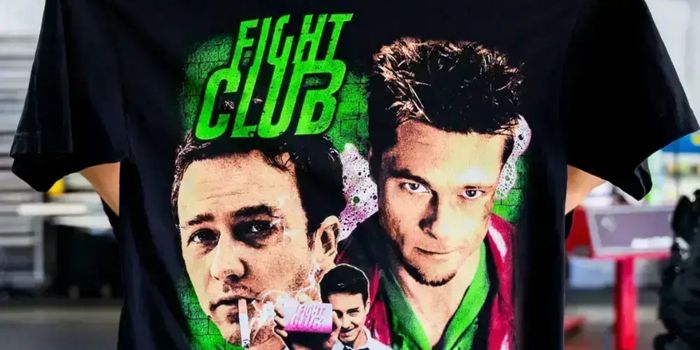

Silk Screen Print Examples

Printed t-shirts are the most common example of silk screen printing. Many logos, patterns and pictures on clothes are made with this method. Further, you can also use this technique to print text and symbols on road safety signs.

Silk Screen Printing Materials

You will get best results when you select the right materials and tools for screen printing. Following are the main resources you may require.

Mesh Screen

Mesh screen is the main material for screen printing. The quality and looks of prints highly depend on the type of mesh you choose. Most are made from polyester. It grips your design and also controls the amount of ink that passes through.

Printing press

In silk screen printing, you can use a printing press to hold the screen in place. It keeps the mesh screen stable while you work. With its help, you can also swap items under the screen for printing.

Squeegees

Basically, squeegee is a tool, which you use to push ink through the screen. It operates with a rubber blade and handle. It has many shapes. You should use a squeegee that exactly matches the screen frame.

Printer & Films

For silk screen printing, you need a printer and films to create your design. The design will be printed on a transparent sheet called acetate film. If your artwork has many colors, each color will be prepared on its own film. These films are later used to make stencils.

Printing Inks

Printing inks give color to your design. Many silk screen printing inks are available. For example: water based, plastisol, plastisol and solvent inks. Always remember that good inks will make your print bright, smooth and durable. Moreover, you must choose inks based on what you are printing and how you want it to look.

Belt dryer

You can use a belt dryer to dry the prints after the ink is applied. It moves the printed item through heat. Then, heat will dry the ink to make prints bright and long lasting.

Silk Screen Printing Process

How does silk screen printing work? This method follows clear step by step working principles.

-

Design Creation

The first step in silk screen printing is creation of your design such as image or text. You can make a design on a computer and then print it on a transparent film. Later, this film will be used to prepare the screen. You should build clear designs because it will provide you sharp and neat prints.

-

Screen Preparation

Now, you have to select a mesh screen and then make it ready for silk printing. The choice depends on the product fabric as well as design details. You need to apply light sensitive (emulsion) coating on the screen.

Then, cover the screen with the film of your design. Light will make the open areas hard. However, the part covered by design still stays soft. You should wash off soft parts, so ink can pass through those open spots.

-

Emulsion exposure

In this step, the screen coated with emulsion is exposed to light. The light will make the emulsion hard in the open areas. But, other parts blocked by your design stay soft and are later cleaned off. In case your design has multiple colors, you should use a separate screen for each color.

-

Stencil Creation

This step makes your design ready on the screen as a stencil. Plus, the soft emulsion under the design will be removed. In this way, open spaces are created on screen where ink can pass. Basically, stencil acts like a guide, which makes sure your design prints exactly where you want it.

-

Setup for Printing

Before you start printing, you have to set up the screen and materials as well. Printing machines can be manual or automatic. You can place the screen on the printing press. After that, align it with the surface you want to print on. You also need to prepare the inks and squeegee. In this way, proper setup will make sure your design prints clearly and in the right position.

-

Design Application

By the use of squeegee, you can apply the ink to the screen. You should spread the ink evenly so it can pass easily through the open areas of the stencil. After that, the ink transfers on the fabric, which will basically create your design. Keep in mind, careful application will make your print clear and sharp.

-

Heat Curing & Finishing

After printing, you are required to provide heat to design. At this stage, you can pass the printed item through the belt dryer. You can also use a heat source to set the ink. This will make your product print strong, bright and long-lasting. Finally, you should check the print for any mistakes and finish the product.

Types of Silk Screen Printing

You can perform silk screen printing in different ways. It depends on the design and material you use. For example: some types are better for bold colors, while others are good for fine details.

Grayscale Printing

Grayscale printing uses different shades of a single color to create a full color image. You can see light and dark areas, which give the design depth and detail. Additionally, more dots in the design give better detail and realistic look.

Grayscale printing operates with combinations of color shades such as CMY or RGB in grey tones. This is best when you need cheaper printing plus black and white designs on fabric.

Duotone Printing

In duotone printing, you can use two colors to create one design. The first half-tone will be printed in black. While the second uses colored ink. These mixtures of colors will add depth and make the design look more interesting. You will see its application to create logos, posters and signs. You should trust its process when you need simple but eye-catching visuals.

Spot Colour Screen Printing

Many designers and manufacturers prefer spot-color screen printing. In this printing style, one solid color is used at a time for each part of the design. As a result, you will get bright and bold prints that really stand out. Generally, you will see it on road signs, traffic boards and safety markings where clear and visible colors are important.

Halftone printing

This printing technique utilizes one ink color of different shades. It creates tiny dots of different sizes to produce shades and gradients (lighter & darker areas). You can also make detailed, smooth and realistic images with halftone printing. Further, you will see it in posters, brochures and detailed graphics where depth and shading are required.

CMYK (4 Color Printing)

CMYK printing uses four colors: Cyan, Magenta, Yellow and Black. When you combine these colors, you can produce a wide range of shades and images. This method is great for detailed designs, photos and signs that need many colors in one print. It always gives you the best and most accurate results.

Simulated Process Printing

Simulated process printing work with a few spot colors to replicate full-color images. It gives you detailed and realistic results without using all four CMYK colors. Moreover, it handles both light and dark shades well. You can use this printing method to design logos, signs and graphics.

Silk Screen Printing Products: Screen Printing Applications

Screen printing is used on many things you see every day. Because it has a wide range of functions and can work well for both small and large printing projects. Following are the major uses of silk screen printing in different types of industries to manufacture several products.

- T-shirts, hoodies & uniforms

- Caps and hats

- Bags and totes

- Posters and banners

- Industrial panels and control boards

- Bottles and jars

- Glass panels

- Medical devices

- Signage (metal signs and plates)

- Packaging materials

- Mugs and drinkware

Products of Jackwin Made By Silk Screen Printing

Based in China, JACKWIN has served the road safety and traffic industry for over 18 years. We proudly serve more than 20000 customers across 70 countries worldwide. Each product meets strict quality inspections.

Furthermore, we use silk screen printing to add clear and durable designs on many of our products. These include parking signs, stanchion posts, warning tapes, safety signs, floor signage and safety vests. You will get all these road safety items in high quality and at competitive prices.

Advantages of Screen Printing

The benefits of silk screen printing make it the top choice for many brands and projects. It combines skill and creativity, which makes it fun and rewarding for anyone who loves manufacturing something special.

- Durability: It makes your designs strong and long lasting. You don’t need to worry about artwork cracking & color fading. This means your goods will stay vibrant and look good for a long time.

- Bright Colors: With screen printing, you will get bold and bold colors. You can make your designs eye-catching and easy to notice. Prints stay bright and easy to see on dark fabric too.

- Less Expensive: For your large projects, this method is a really affordable option. You can save money on large orders without compromising product quality.

- Detailed Designs: Screen printing allows you to print small details clearly. For example: you can include text, complex patterns or precise shapes in your design. This will make your prints look professional and sharp.

- Works on Many Materials: You can use screen printing on many surfaces such as fabric, metal, glass and plastic. Due to this flexibility, you can print your designs on almost any material you want.

- Excellent Coverage: Your items will get smooth and even coverage with screen printing. Because, the ink spreads well across the surface and covers all areas of your design. It lets you print dark designs on light surfaces.

- Speed: You can print hundreds to thousands of items with silkscreen printing. The process works fast and perfectly when you need many prints quickly.

- Customization: It is the best technique to create custom designs that are truly your own. You can choose the colors, patterns and styles to match your vision.

- Smooth & Natural Texture: Screen printing gives your designs a soft and natural finish. The ink blends well with the surface, so your prints feel smooth and high-quality.

Wrapping It Up

If we summarize, silk screen printing is a reliable method to make bold, detailed and durable designs on many products. You should pick the right materials and method for your printing projects.

Do you still have any confusion related to screen printing? Are you looking for road safety items? Contact our experts. We will provide you guidance and quick quotes on traffic products.

-80x69.png)