In-house Manufacturing Capacities

JACKWIN is a leading thermoplastic preheater manufacturer and exporter in China. We have been engaged in road marking equipment and tools since 2008. Here are the manufacturing capabilities that our factory has:

- ISO9001 and ISO14001 quality control system audited.

- Factory workshop area over 10000 sqm.

- Design team of over 10 engineers.

- Advanced manufacturing equipment – lathes, drilling, sawing, engraving, laser cutting, CNC bending, punching, riveting, welding, polishing, and wire drawing machines, as well as powder coating workshops.

Thermoplastic Preheater for Sale

JACKWIN offers a wide range of double-tank, single-tank, and dual-fuel thermoplastic preheaters at competitive factory prices. You can choose from diesel or gasoline-powered engines and different cylinder capacities to match your thermoplastic road marking machines in order to increase your working efficiency, shorten project time, and save your labor costs.

Thermoplastic Preheater by Features

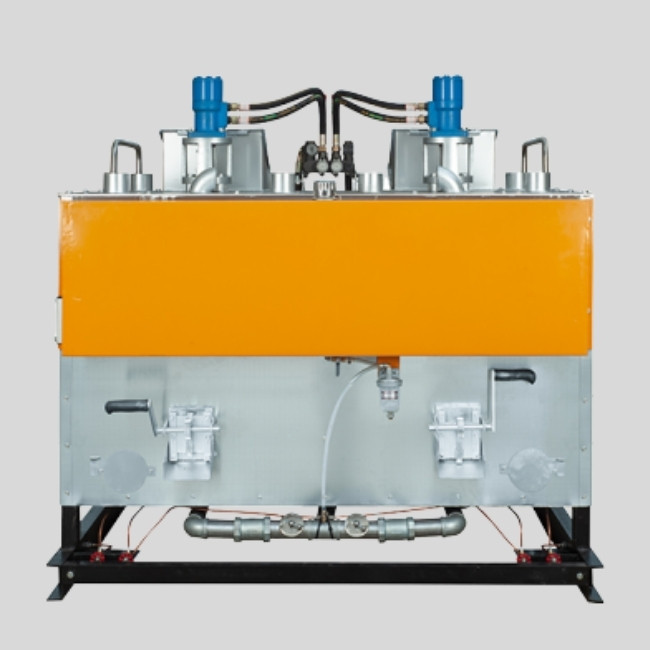

Double-tank, 28ps Changchai diesel engine, AC 220V with leakage protection device, dual temperature control computer thermostat, temperature range from 50-250°C, 70L hydraulic oil tank.

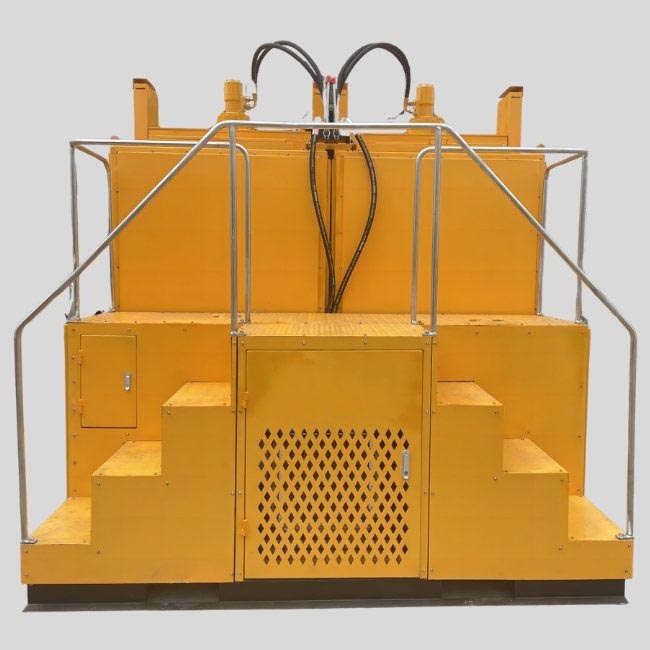

Double tank, oil and gas dual-purpose, upgraded to 1200L tank specially for areas with low temperature and inconvenient refueling, powered by 28ps (20kw) electric start evaporative water-cooled diesel engine.

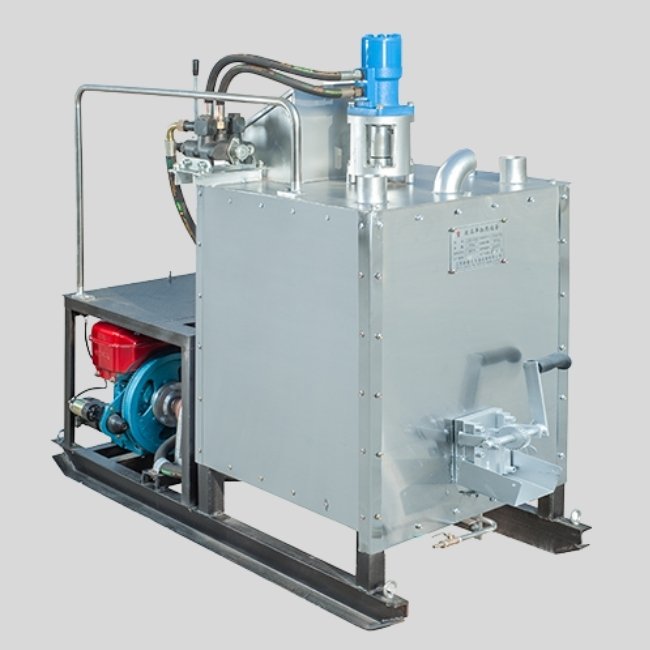

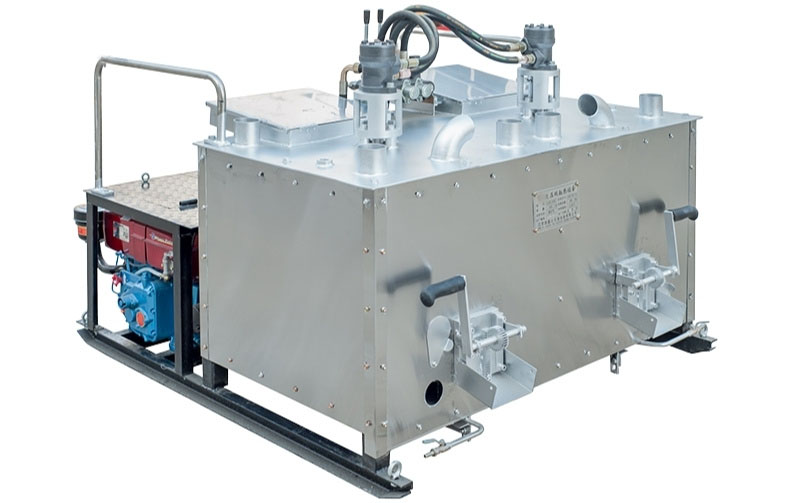

Powered by 16HP electric start evaporative water-cooled diesel engine, liquefied gas and diesel for optional power, 50L hydraulic tank, 100L diesel tank, stainless steel for kettle.

Double tank, direct injection stoves, powered by 16HP electric start evaporative water-cooled diesel engine, using double-layer insulation material, hydraulic transmission with stepless speed change and strong torque.

Powered by 16.5 HP electric starting evaporative water-cooled diesel engine, tank capacity 360 kg x 2, double walls in stainless steel material, overload and overflow device.

Powered by 7.7ps evaporative water-cooled diesel engine, petroleum liquefied gas tank, and temperature adjusted from 0-300°C, turbine gearbox and clutch teeth drived by engine.

Specially designed for parking lot and small project line painting, driven by a 7.5ps electric start evaporative water-cooled diesel engine, temperature adjustment, oil liquefied gas tank.

Designed for Powered by 7.7ps diesel engine, hydraulic tank capacity 40L, 350L cylinder, steel boiler, designed for parking lots, residential areas, factories and docks.

Powered by 6.6ps diesel engine, cylinder capacity 350kg, direct injection burner, using liquefied petroleum gas as fuel, small size and lightweight, easy to transport.

Powered by 38kw 2400r/min diesel engine, Riello diesel version stove, insulation layer 50mm, temperature ranging from +50 to 230°C, automatic ignition and shutdown, actual temperature screen.

Powered by 10P air-cooled electric start diesel engine, double helix full tank heating system, hydraulic bidirectional stepless agitation, with insulation material inside, American diesel stove automatically ignite and extinguish.

- Features

- Applications

- Video

Temperature Control

JACKWIN thermoplastic preheater adopts an intelligent temperature control system, set the temperature in advance, when the temperature is lowered to the set value, the stove automatically ignites and heats up, when the temperature is higher than the set value, the stove automatically switches off and stops heating.

Heating Methods

There are two heating methods, direct heating and indirect heating. JACKWIN’s machines are using automatic ignition and intelligent temperature control burner heating gas or oil directly and by indirect thermal oil heating.

Mixing and Agitation

Our thermoplastic preheaters are available in a variety of mixing and stirring options, including manual, manual clutch gear control, agitator forward and reverse.

Hydraulic Systems

JACKWIN thermoplastic preheaters utilize a multi-way hydraulically reversible control valve to drive the agitator through gears.

Dual Fuel Systems

Our machines are heated using LPG and diesel as fuel.

Truck-Mounted and Trailer-Mounted Designs

JACKWIN preheaters can be mounted by truck and trailer, they are more suitable for large projects in remote areas.

Urban Road Marking

Thermoplastic preheaters are used for urban road marking construction, white and yellow lines, including both sides of lanes, center dividers, pedestrian crossings, crosswalks, prohibited area markings and so on.

Parking Lot Striping

Marking lines in parking lots is also one of the main applications for our preheater.

Highway Pavement Markings

Thermoplastic preheaters are the most used in highway projects because of the distance and remoteness of highways, so they need more power and capacity, which improves painting efficiency.

How to Choose Right Thermoplastic Preheaters for Your Project?

As a professional thermoplastic preheater manufacturer, JACKWIN is qualified to provide expert advice on how to choose the right thermoplastic preheater.

First, you need to understand the size of your project and the expected construction time. This will determine the capacity of the preheater you choose. Large projects require a high-efficiency thermoplastic preheater.

Second, the project size and timeframe will determine whether to choose a single- or twin-cylinder machine. Furthermore, consider mechanical or hydraulic stirring, heating methods (direct or indirect), temperature control systems, and fuel types (thermal or diesel).

Finally, based on the various configurations above and your investment budget, you can make the final decision. In short, JACKWIN can provide you with a one-stop solution, from machine selection to road marking paint and reflective glass beads.

Our Projects

Browse JACKWIN line marking projects as follow:

-80x69.png)