There are two primary options for road marking solutions: cold paint marking machines and thermoplastic road marking machines. When two methods work together, the task is completed more efficiently. Your primary focus in both methods is to concentrate on how to get what type of durability you need, work hard, and find out how much both will cost and how much time they need to dry. Understanding distinctions between the cold plastic vs thermoplastic machines can assist you in selecting the appropriate machine for your project, whether it involves parking lots, highways, or pedestrian zones.

What is a Thermoplastic Road Marking Machine?

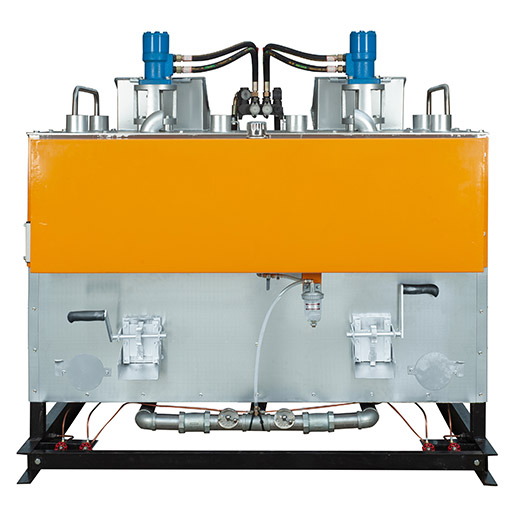

To apply vibrant thermoplastic paint to roads, highways, and other concrete surfaces, an automatic thermoplastic road marking machine is a specialized instrument. It is used to create intelligent and robust signs, such as letters, crosswalks, bolts, and lines, that can withstand severe weather conditions and high traffic volumes.

Thermoplastic marking equipment based powder is heated by the machine to a very high temperature (often 180–200°C) until it becomes liquid. The fabric produces thick, vivid, and long-lasting road markings when it is used because it hardens quickly and adheres firmly to the surface.

What is a Cold Paint Road Marking Machine?

A useful item for marking parking spots without the need for heat is a cold paint road marking machine. Cold paint cold spray technology, which can be solid or water-based, is sprayed directly onto asphalt by various thermoplastic material machines, making it instantly usable. This frame is ideal for low-cost, fast tasks like container floors, city streets, short construction zones, and marking areas. Using this procedure and short drying periods, the machine employs pressured holes to precisely align lines, pictures, or bolts.

Key Differences Between Thermoplastic and Cold Paint Machines

The dissimilarities in performance, cost, and use between thermoplastic and cold paint marking machines should be taken into account while making your decision. The following is a list of important differences that will influence your choice:

1. Material Type:

Thermoplastic Machine: When you attack with a thermoplastic machine, you are handling a dependable powder that demands high temperatures to be utilized. Before it cools, this new soft material establishes a stronger, thicker layer.

Cold Paint Machine: Simply set, a cold paint machine applies liquid paint, either water-based or oil-based, straightforwardly to the surface without heating it up. Even though the paint is easier to handle, thermoplastic is more durable.

2. Application Process

Thermoplastic Machine: Thermoplastic machines function by softening the material into a heated liquid. When you perform plastic sheets on a fire burner professionally, you can use it smoothly.

Cold Paint Machine: Cold paint machines apply paint at a cool temperature using splash or air methods. This simplifies and expedites the process, particularly for made-in-the-home or small-scale projects.

3. Opportunity for Drying

Thermoplastic Machine: Roads may be opened quickly due to thermoplastic stones, which cool and take shape fast, especially in warm weather. For intensely crowded places, an intensely thickening form is ideal.

Cold Paint Machine: Cold paint machines apply paint at a cool temperature using splash or air methods. This simplifies and expedites the process, particularly for made-in-the-home or small-scale projects.

Cold Paint Machine:

Thermoplastic Machine: Roads may be opened quickly due to thermoplastic stones, which cool and take shape fast, especially in warm weather. For intensely crowded places, an intensely thickening form is ideal.

Cold Paint Machine: It normally takes a little more protracted for cold paint to dry. Although it takes somewhat longer to dry, usually 10 to 30 minutes, contingent upon humidity and weather, cold road marking paint dries faster.

4. Durability

Thermoplastic Machine: The best and brightest choice if you want to obtain good marking results is thermoplastic. Regardless of frequent use, it adheres well to surfaces and ends for three to five years.

Cold Paint Machine: Even though cold paint markings are natural to apply, they frequently only last six to twelve months. They are thus more appropriate for temporary locations or less-traveled places.

5. Reflectivity and Visibility

Thermoplastic Machine: Cause thermoplastic markers indicate light well, they are bright and plain to see, increasing their visibility on the road. This determines your with enduring high quality.

Cold Paint Machine: Although cold paint can also be applied to moving objects, thermoplastic frequently has a stronger light-indicating capacity.

6. Equipment Complexity

Thermoplastic Machine: For basic status, it still performs admirably, specifically in dry circumstances. Cause thermoplastic machines feature heating schemes, temperature controls, and more intricate components, they are typically more intricate. To perform your task effectively, you will want supplementary knowledge concerning planning and maintenance.

Cold Paint Machine: Cold paint equipment is plain and straightforward to use. Because you will not have to deal with abundant tanks or intense heat, working accompanying a modest arrangement will be simpler.

7. Cost (Initial and Maintenance)

Thermoplastic Machine: Thermoplastic machines that are fetched (essential and support) have greater direct partnership and operating costs. In order to abandon the powder and perform routine perpetuation on the heating component, you will further bring fuel or control to a transmittal location.

Cold Paint Machine: Cold paint supplies are less costly to purchase and run. They are superior for smaller tasks or those on a short budget because they do not demand heating and are in inferior condition.

8. Surface Compatibility

Thermoplastic Machine: Dimensional or smooth surfaces are ideal for thermoplastic use. You need clean, dry, and oil-free blacktop for optimal results. The bond grant permission breaks if it isn’t.

Cold Paint Machine: Cold paint is less expensive and can be applied to a variety of surfaces, including brief spaces, plant floors, and old or coarse asphalt. It everything well when minimal surface preparation is necessary.

Pros and Cons of Thermoplastic vs Cold Paint Road Marking Technology Machines

Advantages of Thermoplastic Road Marking Machines

-

High-Temperature Heating System

The thermoplastic material is efficiently melted by the powerful heater that comes with your thermoplastic machine. It ensures that the paint is at the proper temperature for a smooth application and a solid bond, whether it is an electric gas burner or a burner.

-

Sturdy Paint Tank (Preheater)

The equipment has a built-in paint holder or preheater. The thick thermoplastic powder is heated in this section so that it may melt and be used. An effective holder prevents the fabric from bunching up or rapidly cooling down, keeping everything toasty.

-

Container Bead Dispenser

sing a container bead dispenser may help ensure that you can see your gadget well, especially at night. Tiny, cautious objects are placed on the wet thermoplastic line marking machine as the paint is applied, making the markings easier for drivers to see in their headlights.

-

Adaptable Widths

Whether you are working with lines for bike lanes or big pedestrian crossings, you can readily adjust their width. You can handle various assignments for classes thanks to the versatility without switching between machines.

-

Handlebar Control and Stable

Wheel Base The device’s sturdy wheelbase and cozy handlebars help you maintain clean, straight lines. Even on uneven or sloping surfaces, it can be used precisely.

-

Self-Driven or Manual Operation

Unexpectedly, you may use a motorized system to operate your thermoplastic machine automatically or by hand during the process. While powered models save you time and effort on larger projects, manual ones are excellent for smaller jobs.

-

Quick-Drying and Durable Advantages

You will love how long it lasts and how fast it dries. Roads may be swiftly reopened to traffic since thermoplastic paint dries and solidifies in a matter of minutes. For many years, it is also resistant to weather damage, fading, and wear.

-

Personalized & Customized Shapes

You Can Modify Bolts, letters, and other street signs can be made by attaching various molds or templates to thermoplastic machines. Without requiring additional materials, you will be able to create even, high-quality exterior markings.

Advantages of Cold Paint Road Marking Machines

The following are the key details about stop marking using cold paint machines:

-

Spray-Based Application System

To completely mix and spray the paint, your cold paint machine either uses an air sprayer or an airless sprayer. While air-spray sprayers employ a compressor for improved control, airless sprayers provide you with crisp, clean lines. Because of this, air-spray sprayers are excellent for intricate tasks and symbols from road marking paint.

-

No Heating Required

The absence of a complex gas burner is one of the main benefits. You can reduce preparation time and energy expenses by using the paint at room temperature. You can begin after filling the paint bottle and weighing it.

-

More Paint Choices

With your cold paint system, you can use a variety of paints, such as water-based paints, materials, and colorful coatings. Because of this adaptability, you can alter the kind of work, the climate, and the regulations.

-

Simple Design and Easy Development

Compared to thermoplastic paint machines, cold paint machines are typically easier to move and handle. It will be simple to move and manage the unit outside with no effort, regardless of whether you see a contract stopping range or close home rooms. Using the same nozzles or pressure controls, you may simply adjust the lines’ width. Bicycle paths can have shorter lines, while crosswalks can have longer lines. You can use this tool to make the ideal markings for your design.

-

Quick Drying Time

Contemporary cold paints, particularly those used indoors, dry rapidly. With that money, you will be able to save time and free up busy areas for work more quickly, which is crucial in crowded cities or during peak hours.

-

Paint Storage Tank with Filter System

A safe paint container, often composed of premium plastic or stain-resistant steel, will be given with your machine along with a drain. When employed, this guarantees a smooth flow and helps avoid obstructions. You can obtain a glass bead vendor for clever designs with certain cold paint equipment. This makes your lines more noticeable in dim or dark environments.

-

Cost-Effective for Short-Term Marking

The ideal choice if you are on a limited budget or need to designate roads fast is a cold paint machine. It is about feeling depressed, requiring careful planning, and using plastic materials to get simple results over time.

Road Marking Materials

The tiny beads help make the lines shine out and keep people safe when using street marking machines, whether they are used for cold paint or thermoplastic, especially at night. Your choice of reflective glass bead will influence its strength, overall appearance, and ability to reflect light. Let us examine the three primary categories:

-

Heavy Metal Glass

Heavy metals like arsenic, lead, or antimony are present in the basic components used to make these tiny balls. If you decide to go with this type, it must be highly reflective and improve nighttime visibility.

But because of their destructive behavior, they continue to endanger the environment and human health. Exercise caution, particularly if your project requires adherence to environmental regulations or affects delicate natural areas.

-

Recycled Glass

The recycled reflecting beads are derived from previously used glass objects, such as windows and jars. This choice lessens waste and your impact on the environment if you are concerned about the environment or are working on a green project.

When compared to clean glass, these items’ clarity or shine may change, but they still reflect light beautifully. Excellent for routine street tasks and daily jobs that call for speedy outcomes.

-

Pure Glass

Hazardous metals and recycled dirt are not present in clean glass beads, which are manufactured from new bottle materials. You will receive a precise estimate, nice shape, and clarity, which will result in road markings that are more reflective, transparent, and long-lasting.

These are frequently utilized in high-end plastic or road construction projects. Select this if you require optimal performance and laminate comprehension of unforeseen circumstances.

Choosing the Right Road Marking Machine

-

When to Choose Thermoplastic Road Marking Machines?

Your objectives and the requirements for your project will determine which road marking instrument is best for you. A thermoplastic road marking paint machine is your best bet if you are working on highways, busy roads, or areas where safety and visibility are deteriorating.

We, as a thermoplastic road marking manufacturer and supplier, offer long-lasting effects, high traction on concrete or asphalt, and improved nighttime visibility with reflecting objects. For a long-term arrangement that requires stability and commitment, the results are excellent, but the initial costs and planning for development require more work and resources.

-

When to Choose Cold Plastic Road Marking Machines?

However, a cold paint marking method offers flexibility and ease if you are in charge of temporary signs, regions with little activity, or inside places like parking lots and storage centers. We as cold plastic road marking paint manufacturers, it is quicker and simpler to start the process, making it ideal for shorter excursions or low-budget situations, without the need for heating gear.

You can see that the intricacy of thermoplastic systems may provide straightforward, efficient outcomes using water-based or fit-for-purpose paints. Select the level of the working criteria, crucial choices, and your supportive manpower.

Jackwin Your Road Marking Glass Beads & Machines Supplier

When it fits with clear, strong, and noticeable design concepts, the right paint and materials are needed. Jackwin‘s superior parking lot signage improves visibility and safety at night as well as during the day. Whether you use thermoplastic or cold paint, our road marking machines ensure that your lines look fantastic and last longer.

That is not all, though; we remain your best bet for computers that assign excessively behaved lines. We are road marking equipment manufacturers our durable plastic equipment and versatile paint sprayers can be customized to meet the needs, size, and budget of any project. Choosing Jackwin is more than just buying a product; it entails joining a group that places a premium on health, safety, and quality in all they offer. Are you ready to improve the way you play road marking games? Now time to partner with Jackwin.

Conclusion

Now that you are aware of the primary distinctions between street marking machines that use thermoplastic and those that use cold paint, it is time to choose the best option for you. Are you prepared for designs that are extremely noticeable and long-lasting? Think of utilizing thermoplastic. If you need a good, affordable solution. Perhaps cold paint is the best option. Are you still unsure? Speak with our knowledgeable staff, and we will assist you in selecting the best machine for your needs according to your price range., Let us improve and make your streets safer today.

FAQs

What is road markings meanings?

Road marking means are road designations are wrapped up with symbols and pictures, lines, or patterns on lanes that coordinate, exhort, or supervise movement, improving security and organization for drivers and travelers.

What is Yellow Road Markings?

Yellow road lines designations are often used to restrict movement in areas that are designated as no-passing zones, or to suggest centerlines and no-passing zones on two-way roads.

What is Broken Yellow Line Road Marking?

A broken yellow line you will pass if it is strong and the conflicting road is clear, but passing is discouraged if there are noticeable conditions or conditions that are weak.

What is the Difference Between Yellow and White Road Markings?

Yellow marking designating are used to indicate the centerline of a two-way roadway, mark no-passing zones, and separate traffic traveling in opposite directions. White marking designating, on the other hand, are used for stop lines, path edges, road dividers, and crosswalks. They also divide lanes that are mobile joined.

Does Canada and USA Have the Same Road Markings?

In essence, both Canada and the United States use similar organizations established by the Manual Uniform Traffic Control Devices (MUTCD) to express that minor regional alternatives permit authorization may exist.

-80x69.png)