Main reason for traffic accidents on roads is poor traffic separation and lack of safety control. You will see vehicles cross lanes or enter unsafe areas. With different types of barriers like concrete barriers, you can solve this problem.

In this article, you will learn about concrete barriers, their different types, uses and benefits. I have also explained some good concrete barrier alternatives you can use for your project.

What are Concrete Barriers?

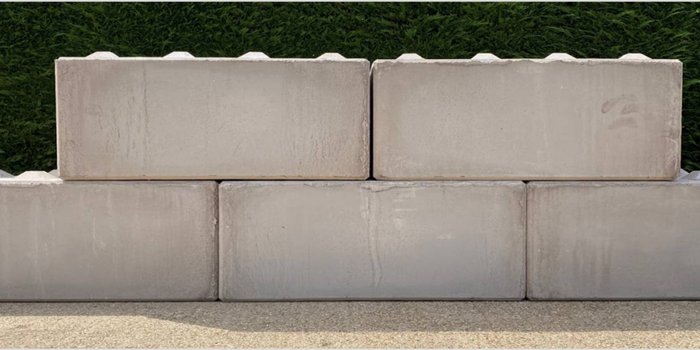

Concrete barriers are strong safety blocks made of concrete. You can use these rigid structures to control traffic flow, protect areas, avoid unauthorized entry and for safety at construction sites. Generally, you will see concrete barriers on roads, highways, bridges and work zones.

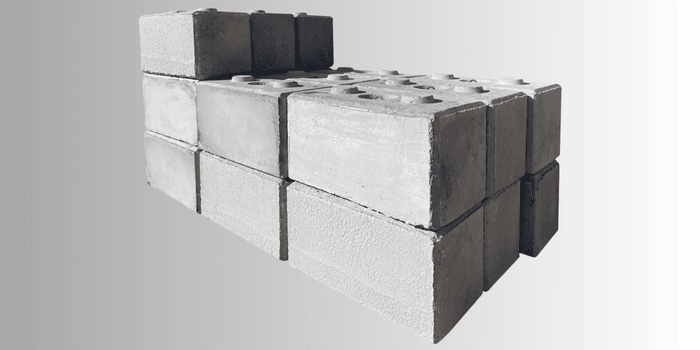

Concrete Barriers

Concrete Barrier Blocks

Concrete blocks are mainly used to block access or create boundaries. They have a simple square or rectangular shape. These blocks work best for area separation, but not for impact control.

- Concrete Blocks Uses: You can use concrete blocks in road construction, building perimeters, parking lots, industrial sites, temporary barriers and bridge protection.

- Advantages of Concrete Blocks: Durable, strong, cost-effective, easy to install, reusable, low maintenance, fire resistant & weather resistant.

- Concrete Construction Barriers: Concrete construction barriers are solid barriers used only at construction sites. You can place them to protect workers and block unauthorized access. They are heavy, so stay in place to keep the site safe.

Concrete Barrier Types

Concrete barriers are available in different types and designs in the market. You can use them for various safety and traffic needs. You should choose a concrete barrier according to the location, purpose, traffic flow and level of protection required.

1. Jersey Barrier or K-Rail Barrier

A Jersey barrier is a concrete barrier used to separate lanes of traffic. It is also known as Jersey wall or Jersey bump as well as k rail. Due to its sloped design, you can use it to reduce vehicle damage if a car hits it.

Furthermore, these barriers stop vehicles from crossing into oncoming traffic. Jersey barriers are used to protect pedestrians/workers and redirect traffic during highway construction.

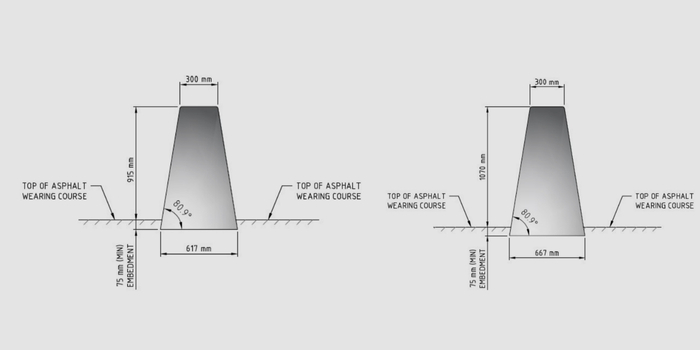

2. F-Shape Barrier

The F-shape barrier is a solid concrete barrier used mainly on highways to separate opposing traffic lanes. Its design has a lower-sloped face that rises to a steeper upper face. This shape reduces the chance of vehicle rollover for smaller cars.

In contrast to the jersey barrier, this barrier hits lower on a vehicle’s center of gravity. Hence, it reduces vehicle damage during collisions and improves overall road safety.

3. Constant-Slope Barrier

Constant slope barrier is a concrete barrier with a uniform slope from bottom to top. You use it on roads and highways to separate lanes and protect vehicles. Its simple design works well when the road height changes.

This makes it more reliable than complex barrier shapes. This way, you can redirect vehicles safely and reduce the risk of car crashes too.

4. Median Concrete Barrier

A median concrete barrier is a strong barrier placed in the center of highways or busy roads. You can use it to separate traffic that moves in opposite directions. With this barrier, you can keep vehicles in their lanes & prevent dangerous cross-median crashes. You will see them on highways and other high speed roads to protect drivers and passengers.

5. Kentledge Concrete Blocks

Kentledge concrete barriers are large and heavy blocks used to provide weight for stability. For example: you can use them as permanent ballast in ships or boats to keep them balanced.

They are strong and stay in place under heavy loads. These blocks are commonly used on construction places and in industrial areas where you need extra weight for safety.

Related: Construction Site Management: Your Detailed Guide 2026

6. Temporary Concrete Barrier (TCB)

A temporary concrete barrier is a movable concrete barrier. You can use it for short-term safety needs. Plus, you can install this barrier to control traffic and protect workers during roadwork or construction. It is easy to place and remove when the work is complete. So, you can install and move them as required.

7. Precast Concrete Barrier

A precast concrete barrier is made under controlled factory conditions before it reaches your site. This barrier offers high strength and consistent quality every time. You can use it to improve safety on roads and construction locations. Its installation is fast and simple, which helps you complete projects on time.

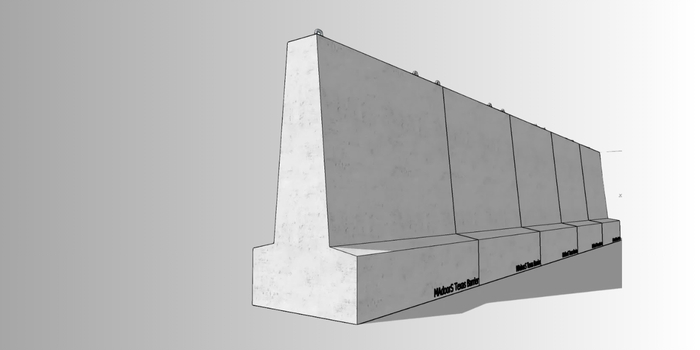

8. Texas Concrete Barrier

The Texas concrete barrier is a tall and heavy concrete barrier. You will find these barriers on highways and roads. Moreover, you can use it to separate traffic lanes and prevent vehicles from crossing into oncoming traffic.

Its vertical design provides strong protection. That’s why it is generally used in areas with high-speed traffic. These barriers are durable and stay in place under heavy impact.

9. Security Concrete Blocks (Anti-Ram)

Security concrete barriers are heavy blocks which you can use to protect buildings and public spaces. You can also place them to stop vehicles to block their entry from restricted areas.

They provide strong physical security and prevent accidents or attacks. Mostly, you will find these barriers at government buildings, airports, flood danger zones and event venues.

10. Portable Concrete Barrier

A portable concrete barrier is a movable & modular concrete wall used for temporary traffic control. or protect work zones. You can place it where you need and remove it easily when the area is clear.

Additionally, you can connect these barriers to create long and adaptable safety lines. It provides temporary safety for roads and events. These barriers are strong and designed for quick setup.

11. Bridge Parapet Wall

A bridge parapet wall is a concrete safety barrier built along the edges of bridges and elevated structures. You use it to prevent vehicles and pedestrians, so they don’t fall off from the bridge.

It absorbs and redirects impact forces of vehicles. In this way, they reduce the risk of accidents. They can also provide noise reduction and enhance the bridge’s appearance as well.

12. Temporary Vertical Concrete Barriers (TVCBs)

Temporary vertical concrete barriers are tall and movable concrete barriers used in construction zones and work areas. Further, you can use them to separate traffic from hazards and protect your workers.

They provide strong vertical protection. Hence, you can quickly install or remove them as needed. With these barriers, you can maintain safety and control traffic flow during temporary road changes.

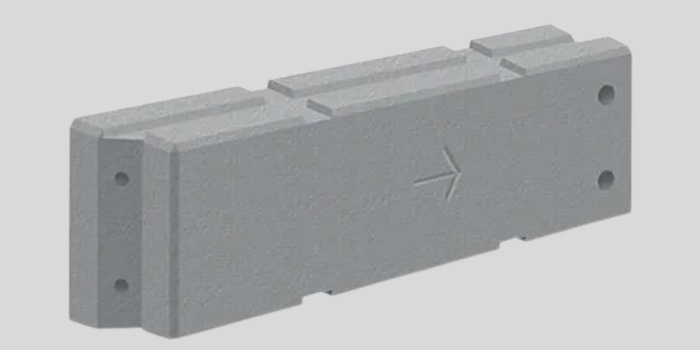

13. Interlocking Concrete Barriers

Interlocking concrete barriers are specially designed barriers. You can connect them together to form a continuous line. Then, you have to install them to guide traffic, separate lanes plus protect work zones.

Their interlocking design keeps the barriers stable and prevents gaps between sections. These barriers are durable and easy to install and move when needed.

14. Noise Reducing Concrete Barrier

A noise reducing concrete barrier is also designed to block and absorb traffic noise. You can place these barriers along highways and residential areas to protect people from loud sounds.

To make these barriers, engineers used special concrete which actually reduces sound reflection & transmission. So, you can use them to improve the comfort of nearby communities.

Can Concrete Barriers Be Moved or Repositioned?

Yes, some concrete barriers can be moved or repositioned. For example: you can relocate temporary or portable barriers to adjust traffic flow or protect new work areas.

However, heavy barriers such as median or security blocks mostly require cranes or special equipment to move safely. You should handle concrete barriers carefully to avoid any harm to them and for strong protection.

How To Avoid Cracks in Concrete Barriers?

Cracks in concrete barriers can reduce their strength and safety. Hence, you can take the following simple steps to prevent cracks and keep barriers strong.

- You should use high quality concrete with proper mix ratio.

- The addition of steel reinforcement can also resist stress and impact.

- To prevent shrinkage, it’s important to give time to harden and dry correctly after a concrete barrier is poured.

- You have to place barriers on stable and well prepared ground.

- Always remember to perform regular inspections and maintenance to tackle small cracks early.

Best Alternatives To Concrete Barriers

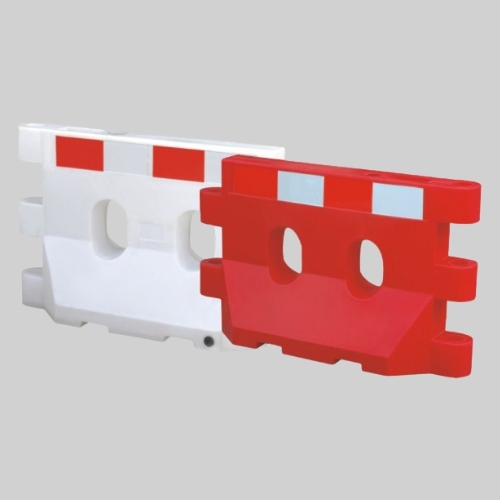

Well, concrete barriers are strong & durable but there are lighter and more flexible options available. For your road or construction project, we advise you to consider plastic barriers and water-filled barriers. Because they also provide the same protection as concrete barriers, but are more affordable choices for you.

Plastic Barrier Benefits

- Plastic barriers are lightweight and easy to move/reposition.

- Quick and simple to install without heavy machinery.

- They are affordable compared to concrete barriers.

- Ideal for your temporary projects or changing traffic patterns.

- They are durable and weather resistant.

- You can fill them with sand or water for extra stability if needed.

Advantages of water-filled barriers

- They are easy to transport when empty. Hence, you can reduce logistics costs.

- These barriers are very strong and stable when you fill them with water.

- They are reusable for multiple projects, which makes them cost efficient.

- Quick to set up and remove, so save your time on-site.

- Lightweight to handle before filling, which also reduces labor effort.

- Flexible for different project sizes and road layouts.

Frequently Asked Questions

How Long Do Concrete Barriers Last?

The lifespan of concrete barriers can be anywhere between 50 years to a century. However, it highly depends on the use of barriers. For instance: if you place a barrier outdoors where it is exposed to harsh weather, it can only last for 20 years.

Can You Use Concrete Barriers With Mesh Fence?

Definitely yes. You can use concrete barriers with a mesh fence. You need to place the fence on top of the barrier to create a taller safety or security barrier. With this combination, you can stop vehicles and prevent unauthorized access.

How are Concrete Barriers Placed?

To place concrete barriers, you will need forklift or specialized lifting equipment. You should install barriers in a way that they are properly aligned and stable. But, some barriers are made on site with the use of slipforming. Both methods need site preparation.

What is the Standard Height of a Concrete Barrier?

The average height of a concrete barrier is 32 inches (approx. 81 cm). The taller barriers are around 42 inches high and shorter ones are 2 feet tall. The concrete barrier height varies according to traffic speed and safety standards like MASH or NCHRP 350.

Conclusion

Concrete barriers have a major role to keep roads and work zones safe. Each barrier offers a specific level of protection. You should choose the right type of barrier based on your requirements.

We are a professional supplier and manufacturer of road barriers. You can request custom options for your project and get barriers at factory price. Contact us now!

You may also like these helpful topics:

Water Filled Barriers Guide For Road Construction Companies

What Are Stage Barriers? Types, Uses, Benefit & Rules

-80x69.png)