As a construction site manager or facility manager, you often use construction cones along with other barriers at your project site to protect your workers and direct traffic. However, it is crucial for you to learn about different cone types for construction settings.

In this guide, we’ve explained ten different types of construction cones and their variation in colors, sizes, weights, materials, and dimensions. By the end, you’ll also learn about choosing the right construction cone type for your project. So, let’s get in!

Importance of Construction Cones for Traffic Safety & Work Zones

The construction cones (often known as road cones, traffic cones, highway cones or safety cones) serve several purposes.

One primary purpose of construction cones is ensuring worker safety. When you place cones properly around the work area, they create a visible-and-physical barrier between traffic and the active work zone. That informs road users that a repair or construction task is in progress.

This way, cones restrict unauthorized people’s entries and redirect them toward safe, designated paths. And that’s how cones fulfill their second purpose, promoting pedestrian safety and directing traffic flow.

Beyond these basics, construction cones even help in reducing driver confusion. For instance, there’s lane closures or detours due to construction work. Here, cones guide vehicles in the right direction, enabling them to navigate smoothly.

Lastly, local or federal safety standards require every construction facility to use construction cones at worksite sites. So using them also ensures your compliance with standards.

10 Different Types of Construction Cones and Their Uses

-

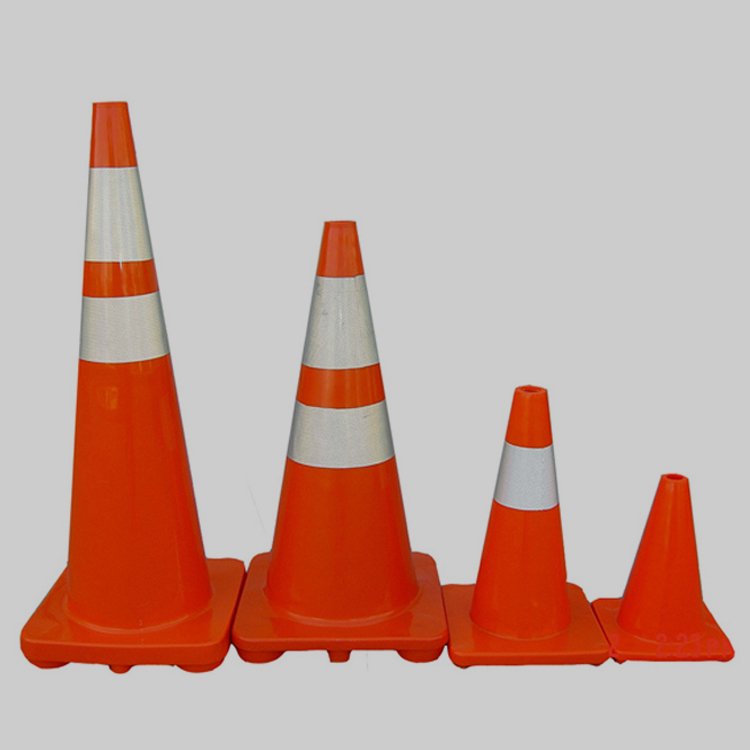

Standard Orange Construction Cones

Standard orange cones are widely used cones in construction sites. These are generally in bright orange color along with reflective strips that make them highly visible at construction sites and perfect for use in both day and nighttime.

JACKWIN manufactures them with durable PVC, PE, or rubber material in various size ranges (12, 18, 28, and 36 inches). You can use them solely or along with other barriers near general roadwork, construction zones, and lane closures. Since they are cone-shaped, they’re lightweight and also stackable.

Best for: Road construction, lane merging, or detours on highways.

-

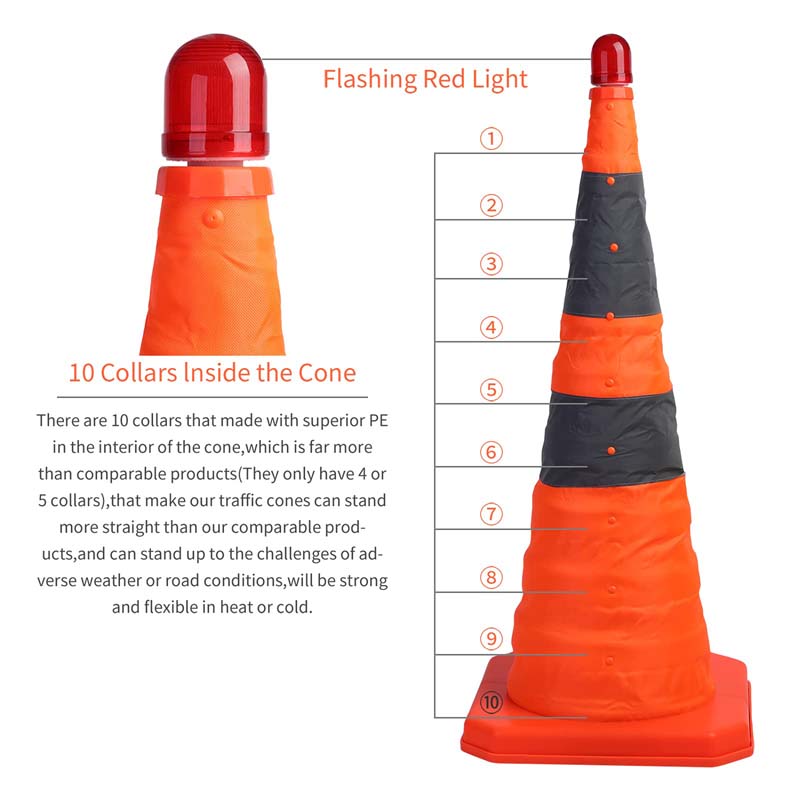

Collapsible Construction Cones

Collapsible cones (often known as Pop-Up cones) are foldable, lightweight and retractable cones. These cones are actually made for temporary and quick use. When there’s a need, just retract them and after use, simply collapse and store them.

And that’s the reason why they’re perfect for emergency responders and maintenance crews. Jackwin made them with premium polypropylene (PP) or nylon material and equipped them with reflective bands and mini-LED (at top) for enhanced visibility. They are also lightweight and easy to transport in bulk.

Best for: Emergency stops, roadside incidents, or portable safety needs.

-

Reflective Construction Cones

As the name explains, they are reflective cones and especially designed to utilize in nighttime or low light conditions. Jackwin equipped these cones with reflective film. That way, they reflect and bounce vehicle headlights directly into the driver’s eyes, making them easier to notice.

On top of that, their reflective sheeting is wear and UV resistant, so buying them once means they stay durable for a longer period. If you manage a construction project 24/7, during nighttime or in areas with low lighting, using reflective construction cones is a must.

Best for: Night construction, tunnels, and dim parking areas.

-

Heavy-Duty Construction Cones

Heavy-duty construction cones are heavy and designed for use in high-traffic areas and tough conditions. These cones are typically tall, thick, durable, and have weighted bases equipped at the bottom (for added stability). Jackwin made these cones with heavy-duty material (like PVC or rubber).

They can easily withstand heavy impacts and strong winds (without falling over). You can use them for long-term projects in construction sites on any high-traffic zones, industrial sites, intersections, or where durability and stability of cones are non-negotiable.

Best for: Busy roads, industrial setups, or windy outdoor conditions.

-

Mini Construction Cones

As the name suggests, these cones are small (approx. 12 inches) and lightweight. They are actually designed for use in closed spaces and indoor settings. These cones are typically made with plastic material, are light-weight, in bright colors, and stackable.

Although they’re small, you can use them for quick maintenance projects in schools, event setups, warehouses, bike lanes, parking lots, commercial buildings, or indoor maintenance zones. Some models of these cones even feature reflective strips to enhance visibility.

Best for: Warehouses, schools, indoor repairs, and event markings.

-

Weighted Base Construction Cones

Weighted base construction cones are generally like the other cones, but they come with weight base accessories (for added stability). The weighted base is equipped at the bottom to help cones stay stable in harsh conditions. Jackwin made these cones with PVC or rubber and weight bases with rubber material.

These weight bases are fitted and hold construction cones in its place to prevent them from tipping over. You can use these weighted base construction cones for long-term projects at sites that experience high vehicle speeds, weather changes, or sites that require frequent monitoring.

Best for: Windy locations, construction on highways, or sloped roads.

-

Colored Construction Cones

Colored construction cones serve the same function. But they cater to specific application zones. Unlike orange construction cones, these cones are available in various colors, such as blue, green, red, and yellow. For example, yellow construction cones at your worksite indicate slippery conditions.

Jackwin made colored construction cones with PVC or plastic material. Some models also include reflective bands for high-visibility in day and nighttime. You can use them to mark caution zones at your worksite, parking lots, events, or reserved spaces.

Best for: Event areas, parking lot management, utility works, or school zones.

-

LED Lighted Construction Cones

LED lighted cones, as the name suggest, are equipped with mini-LED (at top) and reflective sheets. The outer shell of LED is made with traffic-grade PVC and inner include electronics. These cones are actually built for visibility in low-light or nighttime conditions.

The LED on cones is powered up with rechargeable batteries or solar panels. In the daytime, they are highly visible due to reflective sheeting. During nighttime, their LED turns on and enhances the cones’ visibility even further. You can use them during nighttime construction projects or where cones’ reflectivity isn’t enough. They’re commonly used at night in construction zones, dark highways, tunnels, or remote roads.

Best for: Night roadwork, tunnels, airport runways, or low-light areas.

-

Smart Construction Cones

Smart or let’s say intelligent construction cones are high-tech safety tools. These cones are equipped with sensors, GPS, or Bluetooth modules that are connected with digital systems. Actually, these cones detect real-time changes around the site and share that data to managing authorities.

Not only are these cones smart, they are tough, weather-resistant, durable, and a perfect option for long-term outdoor use. You can use intelligent traffic cones in city infrastructure and high-risk areas. They help you monitor and manage work zones remotely with better accuracy and response time.

Best for: Smart city projects, temporary detours, or AI-integrated traffic zones.

-

Cone Bars (Expandable Bar Attachments)

Apart from all other construction cone types, these cone bars are equipped with accessories holding capability. These cones are designed in a way that they let you attach safety signage, chains, safety tapes, and reflective collars. You can utilize these cones to create a temporary barrier at your worksite.

These cone bars are lightweight, extendable bars, highly-visible, made with plastic, and have hooks at top (to attach accessory). They’re perfect for areas where you need to block lanes, restrict road access quickly without installing permanent fencing. At nighttime, their visibility is improved with reflective tape or bold color stripes.

Best for: Crowd control, maintenance zones, temporary lane closures, or indoor work areas.

Color Variations and Their Meanings

- Orange: Standard color for caution and danger

- Green: Safety instructions or directional guidance

- Yellow: General caution for non-traffic hazards

- Blue: Restricted access, accessible zones, or law enforcement

- Red: High danger or emergency zones

- White: Neutral guidance or crowd control

- Black: Aesthetic or specific branding use

Material Differences: PVC, PE, HDPE & Rubber

| Material | Difference |

| PVC | This material is flexible, durable, impact-resistant, weather-resistant, and ideal for high-traffic areas. |

| PE | On the other hand, PE is lightweight, cost-effective, and ideal for temporary or short-term projects. |

| HDPE | HDPE is a more rigid material among others. It is more durable, weather-resistant, impact-resistance and stays longer. |

| Rubber | This is a heavy and stable material, perfect for windy or rough environments. |

Construction Cone Dimensions and When to Use Each Size?

Well, as we mentioned earlier, construction cones come in various sizes, varying from 12, 18, 28, and 36 inches. However, each size serves a specific purpose depending on the use case. In the section below, you’ll learn what size of cone you should choose based on your needs:

- 12-Inch Cones (1 foot)

These are the smallest cones (often known as mini or slim cones). They are very lightweight and portable. That’s why you can use them for indoor construction projects. Such as warehouses, schools, or parking garages.

- 18-Inch Cones (1.5 feet)

They are slightly taller and hence more visible. They are also light-weight, but are more visible than 12-inch cones. So you can use them at low-traffic sites. Such as parking lots, walkways, drive-thru lanes.

- 28-Inch Cones (2.3 feet)

This is a perfect and standard size as per the MUTCD standard. For construction projects at low-speed roadways and moderate traffic control, you can use these cones. Since these cones have reflective collars, so they’re perfect for both day and nighttime use.

- 36-Inch Cones (3 feet)

These are heavy-duty cones, are tall and more highly visible even from a distance. You can use them for construction projects in high-speed roads, highways, and intersections.

- Over 36 Inches (Jumbo Cones)

Cones over 36 inches are generally customized cones. They can be used in special conditions like industrial sites, large-scale events, or heavy construction areas. These big cones deliver maximum visibility and impact resistance.

How to Choose the Right Cone for a Construction Project?

The selection of the correct construction cones among several types entirely depends on the environmental conditions, such as the traffic volume, visibility conditions, project duration, and even your budget.

So when you need to choose a construction, first, check the location and traffic level. For example, if your project site is a busy highway, we suggest you go for 36-inch heavy-duty cones with reflective collars. These are tall, visible, stable, and compatible for use in tough conditions.

But if you’re just managing a short construction project at a school, parking lot, or indoor area, 12-inch, 18-inch, or collapsible cones (with mini-LEDs) will do the job.

Also, if your team is operating 24/7, after dark or during foggy mornings, we suggest you use reflective, 28-inch ad LED lighted cones for better visibility. On top of that, if the worksite ground is uneven or there’s a fear of cones falling over, you can also go for weighted base or rubber-made cones.

Lastly, the choice depends on your budget and how often you’ll reuse cones. If you manage a short or one-time project, collapsible or PVC cones are a cost-effective solution. But for long-term projects, we suggest you invest in durable rubber or HDPE cones.

Customize Construction Cones – When and Where to Get Them?

Let’s first discuss when you should get customized construction cones for your construction facility. You should go for custom cones when you need to:

- Display your company branding (logo or name)

- Mark high-priority or restricted areas

- Enhance your business branding and provide a hotline number

- Provide different cones to different departments or zones

- Use cones for promotional events or crowd control at brand sites

- Stand out at a worksite while operating with other construction facilities

Now, where can you get them? JACKWIN is the leading and trusted brand for construction cones, when it comes to high-quality ready-made, custom-made and affordable cones.

Our professional team can also make customized construction cones on client’s demand in color, size, material, reflective sheeting, accessories, stickers and printed messages.

If you order from us in bulk, we deal with you at competitive wholesale rates. To place your order, check our construction cones catalog or contact us today for custom cones!

Wrap Up

All construction cones types serve the same purpose but what differentiate them is their characteristics, sizes, and their ability to cater to different environment and site conditions. That’s why learning about construction cones types in terms of key features, and sizes, color is crucial to make correct selection and ensure extra edge safety of your workers and other road users and also compliance with MUTCD standards.

-80x69.png)