Various Water Filled Jersey Barriers for Sale

JACKWIN manufactures and supplies different sizes and weights of plastic water filled barriers at competitive prices, covering blow molded water filled jersey barriers and rotational molded water filled traffic barriers.

Discover a range of water filled barriers with the highest quality at affordable prices from JACKWIN.

What are Water-Filled Barriers?

Water-filled barriers, also called jersey barriers, are made up of brightly colored HDPE material which are designed to divide the road or to be used as an obstacle barrier. They are usually small in width at the top and large in width at the bottom. There are holes on the top to inject water or sand to increase the weight. They are generally used in road traffic facilities and are often seen at intersections of highways, urban roads, and flyovers.

Water-Filled Barriers by Features

JACKWIN offers a full range of plastic water-filled barriers manufactured by blowing and rotational molded processes, please browse the following and choose to buy for your project.

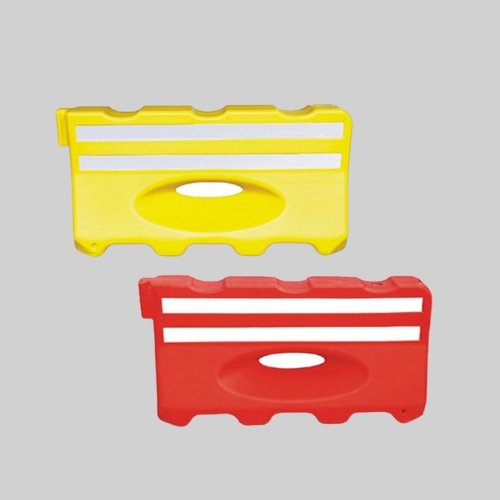

Size 1300x370x650mm, made of HDPE, water capacity 200kg

Size 1500x370x800mm, designed for traffic and road

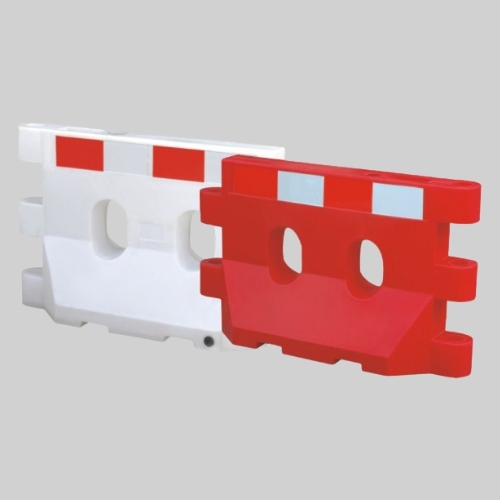

Size 2000x400x800mm, designed for road construction

Size 1000x500x600mm, foldable and easy to storage

Manufactured by rotational mold and made of HDPE.

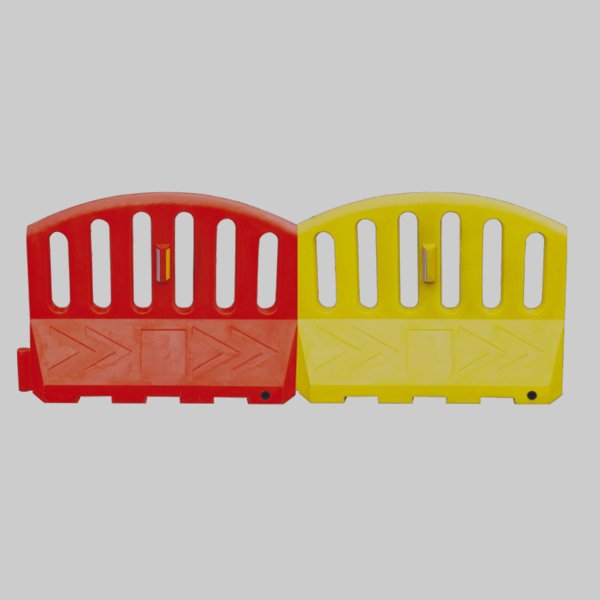

Interlock system, made of HDPE by rotation mold tool.

Size 2000x1000x150x500 mm, rotational mold, weight 18 kg

Size 900X1500X170X450mm, weight capacity 250kg, minimum weight 15kg.

Size 1830X810X250X460mm, rotational mold, customizable weight.

Water-filled Barrier Selling Points

JACKWIN’s water-filled barriers have many advantages and features, which are listed below:

with reflective film to make it more bright at night and red or yellow to make it more visible.

not break when crashed by vehicle.

easy to carry and move as it is lightweight.

can work from -60℃ to 60℃.

stackable for easy shipping and transportation.

100% new HDPE material.

can be used outdoors.

water-filled barriers can be connected and expanded to the length you need.

Wholesale and Customize Water Filled Barriers

JACKWIN wholesales and customizes various styles of water-filled barriers. We can also customize your logo with debossed molding to help you expand your brand influence and increase your business volume.

Stackable Water Filled Road Barriers

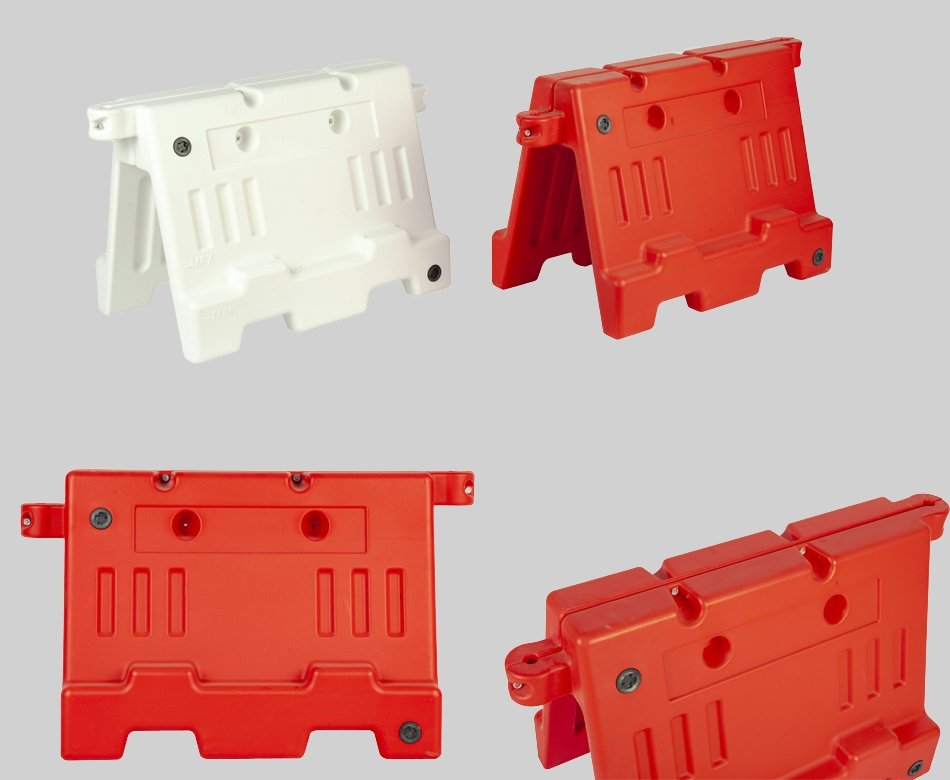

JACKWIN’s plastic water-filled road barriers are made of virgin HDPE material by blowing molded production. Our barricades are designed to be stackable and interlockable, which is our initial design concept. They come in red, white, and orange for your option, can be filled in sand and water, are widely used for traffic management and highways, and can withstand crash impact.

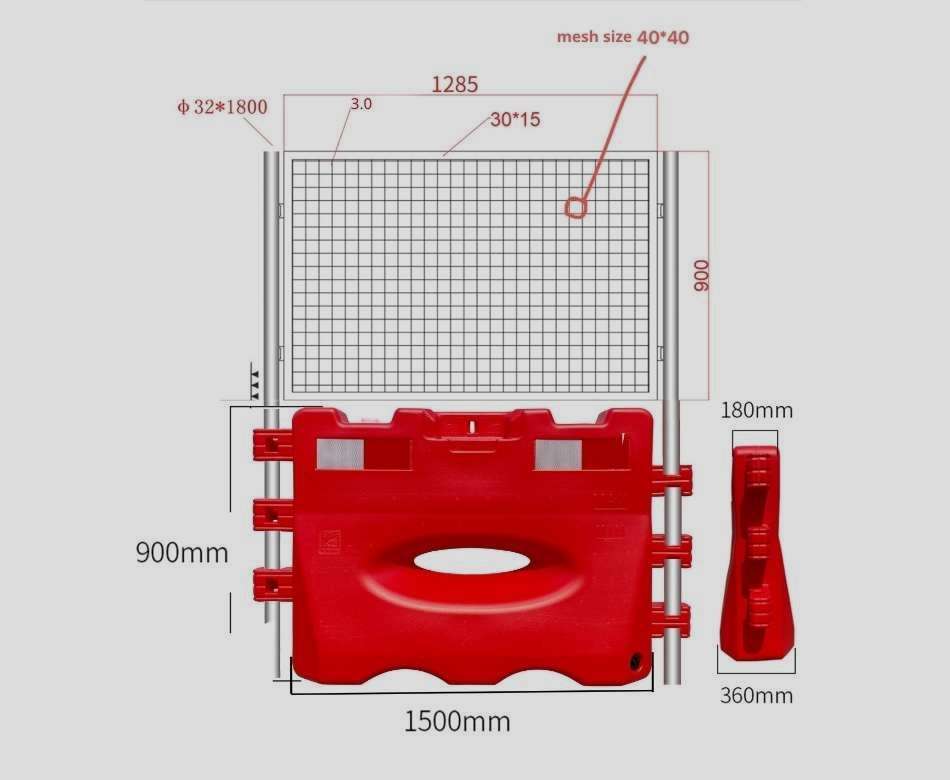

Water Filled Barriers with Fence

Our water-filled barriers with fence systems are mainly designed for the Hong Kong and US markets. We use blow molding production technology, the material is polyethylene plastic, and they are connected and locked by galvanized steel posts. It consists of jersey water barriers in the lower part, and fence panels in the upper part like a chain-link. It’s designed to safeguard, channel traffic, pedestrians, construction sites, work zones, excavation sites, parking areas, roadblocks, and checkpoints.

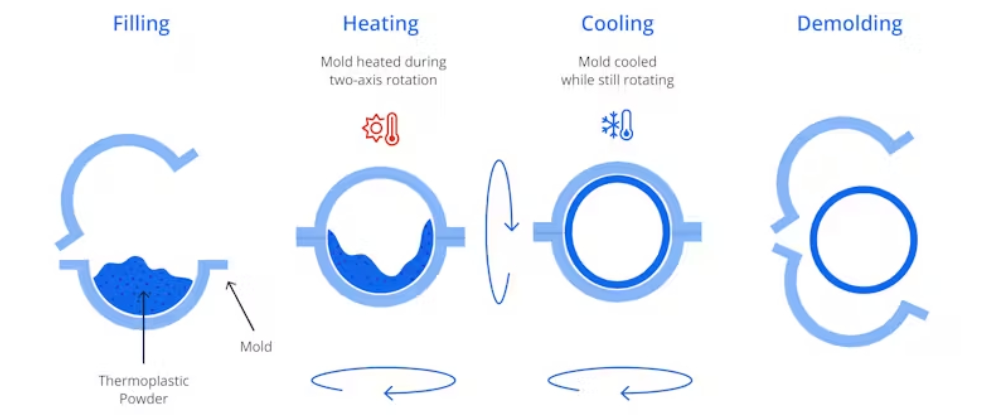

Rotational Mold Design

JACKWIN provides rotational molding customization for water-filled barriers. We can design 3D drawings based on your ideas or requirements, including the capacity, height, color, logo, and overall structure (water inlet position and reflective tapes) of the water barriers. Our molds are made of high-strength aluminum or steel, ensuring that the produced samples highly meet your expectations.

JACKWIN has extensive experience in water-filled barrier mold manufacturing and is familiar with the requirements in different countries, guaranteeing a mold development time of 15-30 days. If you worry about the cost of mold development, our factory can share or refund the mold costs within the order. Send us an inquiry for more details about water barrier mold development.

Water-filled Barriers with Fence Extension

JACKWIN water-filled barriers with extended fences provide secure and versatile solutions for roadworks, traffic diversion zones and construction sites. With a galvanized steel fence panel installed on top of water-filled barrier, the anti-climb mesh frame is stable, weather-resistant and durable, preventing the access of unauthorized persons. Designed with reflective strip tape, our barriers are highly visible in low-light conditions. The fences can be connected to each other easily and the panel height can be customized to meet your various needs.

Water Filled Flood Barriers

Water-filled flood barriers designed by JACKWIN can replace your old-fashioned sandbag method to prevent floods. Our flood barrier has the following advantages and features:

- It is easier to obtain materials. Fill in the water from your site, which is more convenient and faster than sand.

- Water has better fluidity than sand. If the ground is uneven, the water will quickly take shape according to the shape of the ground.

- We use PVC laminated fabric, which is more wear-resistant than sandbags.

- After the flood prevention is over, our water barrier can be removed faster than sandbags.

Our water-filled flood barriers are used for dams, garage door waterproof barriers, flood gates, home flood barriers, home flood barriers, residential flood barriers, flood waterproof barriers, or flood gates. If you are looking for water-filled flood barriers, then you don’t have to look any further, we are your best choice.

Water Filled Traffic Barriers

JACKWIN water-filled traffic barriers are designed for airport runways, taxiways, and delineating airport construction areas.

Our barricades are featured as follows:

- Lightweight, and stackable

- Quick install and easy remove

- Chain link design

- Impact resistance

- Fill with water or sand

- High visibility

- Portability

Resources

For more products and learn about JACKWIN, please click to download our catalogue as following:

Blow Mold Water-filled Barrier VS Rotational Mold Water-filled Barrier

- Material: Both of these types of production methods use HDPE material, blowing molding production can use some percent of recycled material, but rotational molded production requests 100% virgin HDPE material.

- Appearance color: The color of blowing molding barrier will be darker and not fresher than rotational molding water filled barrier.

- Weight: The weight of rotational molding will be heavier than the blowing molding. It will have good impact resistance compared with blowing molding water-filled barriers. The blowing molding water-filled barrier will be easier to carry and install than rotational molding.

- Thickness: The rotational molding water-filled barrier thickness is usually from 4mm to 6mm, otherwise, the blowing molding water-filled barrier thickness is only 2-3mm. So rotational molded barrier has high durability and impact resistance.

- Anti-collision capability: The anti-collision capacity of rotational molding water-filled barrier will be preferred to blowing molding water-filled barrier as heady duty weight and thicker thickness.

- Lifespan: The lifespan of rotational molding can reach at least 4 years while blowing molding is generally 2 to 3 years in the same condition.

- Production efficiency: Blowing mold can manufacture 300 pcs of water-filled barriers per day, but rotational mold only can produce 20 to 30 pcs of water-filled barriers per day, so the blowing molding production efficiency will be much higher than rotational molding.

- Energy consumption: Blowing molding water-filled barriers will be more energy-efficient and environmentally friendly than rotational molding due to high production efficiency and energy consumption.

- Cost: Low cost of the blowing molding as the less labor, high production efficiency, low material requirements, low material cost and low energy consumption.

Plastic Water-filled Barriers Applications

JACKWIN’s water-filled barriers have strong impact resistance, UV resistance and oxidation resistance, and have many uses, such as barriers on both sides of motorsport or karting tracks, isolation guardrails on both sides of stadium tracks, etc. Moreover, we list some of the following applications.

Our Production Capacity

We have two production lines, one is a blow molding line and the other is a rotational molding line. According to the customer’s choice and the type of water-filled barrier, we choose the appropriate mold to produce water-filled barrier for the customer.

This is our large blow molding machine, which can produce a maximum barrier length of 2 meters and a weight of up to 20 kilograms. Moreover, our machine is highly efficient and can manufacture a water-filled barrier every 4 minutes.

The water-filled barrier produced by our rotational molding machines is relatively thick, and has strong impact resistance and good quality, but has high production efficiency and high energy consumption.

The production of rotational molding molds is very simple. Compared with blow molding molds, the production cost of rotational molding is low. Our factory can make rotational molding molds by ourselves.

Its structure is quite special, consisting of two barriers, front and back, which are fastened together with screws, and the two sides are interlocked and can be connected with pins.

More About Our Water-filled Barriers

If you need to learn more about our water-filled barriers, please check the following specifications, or you can contact our sales to discuss.

- Specifications

| Item Number | Material | Length | Top Width | Bottom Width | Height | Net Weight | Water Capacity | Color |

| SM-001 | HDPE | 1300mm | 180mm | 370mm | 650mm | 8.5kgs | 200kgs | R / Y / W |

| SM-002 | HDPE | 1650mm | 150mm | 410mm | 650mm | 9kgs | 300kgs | R / Y / W |

| SM-003A | HDPE | 1400mm | 145mm | 400mm | 800mm | 7.5kgs | 400kgs | R / Y / W |

| SM-003B | HDPE | 1500mm | 180mm | 370mm | 800mm | 9.5kgs | 250kgs | R / Y / W |

| SM-004 | HDPE | 2000mm | 145mm | 400mm | 800mm | 17kgs | 400kgs | R / Y / W |

| SM-005 | HDPE | 1200mm | 80mm | 260mm | 600mm | 6kgs | 60kgs | R / Y / W |

| SM-006 | HDPE | 1500mm | 150mm | 430mm | 1200mm | 14kgs | 200kgs | R / Y / W |

| SM-007 | HDPE | 1000mm | 250mm | 500mm | 600mm | 6.5kgs | 200kgs | R / Y / W |

| SM-008 | HDPE | 1000mm | 120mm | / | 180mm | 2kgs | 100kgs | R/Y/B/W |

| SM-009 | HDPE | 1000mm | 200mm | / | 250mm | 2.8kgs | 100kgs | R/Y/B/W |

| SM-010 | HDPE | 1000mm | 300mm | / | 350mm | 4.85kgs | 100kgs | R/Y/B/W |

Customers' Feedbacks

Our water-filled barriers are designed to 4 years usage lifetime which can withstand weather conditions and can resist impact from vehicles.

Our water-filled barriers can be quickly installed by filling in water or sand at the site. Remove water or sand in the same simple way.

We generally packed the water-filled barriers by nude packing as the big volume and sizes.

Related Product

Why is the Weight of Water-filled Barriers Limited?

JACKWIN produces various kinds of water-filled barriers by rotational molding, and we have a minimum weight limit of 15kg.

Why do JACKWIN rotational water-filled barriers have a minimum and maximum weight limit?

Rotational molding involves heating a hollow mold filled with plastic powder slowly. The melted plastic dust flows around the inside of the mold, and it lays out a layer upon layer of plastic until the inner wall of the mold gets an even coat. After cooling, you get a one-piece and seamless hollow product.

If the amount of plastic powder is not enough or your mold has sharp corners and edges, melted plastic won’t evenly coat every inch, especially in complex areas with corners. Water-filled barriers made by insufficient plastic particles lead to uneven and thin thickness(standard wall thickness is commonly more than 1.5-2mm), which will crack after continuous movement or water filling. JACKWIN sets a minimum weight for our water-filled barrier to ensure the quality and reliability.

When plastic powder is filled excessively, it leads to a thick coating. The innermost layer of PE plastic particles cannot be fully melted while the outermost layer of plastic powder has begun to turn yellow during the heating process. This process is like cooking rice in a pot in daily life. The rice on the bottom layer is mushy while the rice on the top layer is still raw. Water-filled barriers with too thick walls are prone to cracking, deformation, and uneven quality inside and outside. It’s not an ideal solution for you to make a solid or super heavy water-filled barrier by filling enormous amounts of plastic particles.

-80x69.png)