You know that sidewalks, parking lots, or building entrances are a bit higher than the road surface. So, for people with disabilities or using wheelchairs, even vehicles, it becomes difficult to move between a road and a sidewalk/ parking lot. In such situations, curb ramps benefit people with disabilities and pedestrians the most by creating a smooth surface.

But that’s not all about it. Curb ramps come in several types and materials, catering to different needs. So if you are a construction company, contractor, homeowner, or own a rehab center, residential community, it’s important for you to understand curb ramps deeply. And that’s why we’ve prepared this guide, including everything for you.

What is a Curb Ramp?

A curb ramp is a type of pedestrian or vehicle accessibility device. Often known as curb cut, slope ramp, dropped curb, or kerb ramp. It is a small sloped surface that is placed to connect the sidewalk/parking lot to the street level. This helps people move vehicles, wheelchairs, strollers and smoothly pass between a raised sidewalk and the road (without tripping and slipping).

Working of Curb Ramp

Here’s how curb ramps work:

Whenever a pedestrian, wheelchair user, or driver approaches the edge of a sidewalk or elevated surface, they don’t face a sudden drop or hit. Instead, the curb ramp provides a smooth slope between the lower street level and the higher sidewalk (vice versa).

As the person moves forward, the curb ramp’s sloped surface lets them gradually move up/ down. That way, any mobility devices (wheelchairs, walkers, or scooters) and vehicles roll smoothly without getting stuck or tilted. After the individual reaches the end of the ramp, they’re already aligned with the road or walkway surface.

Apart from that, curb’s tactile warning strips or textured surfaces do the guidance job too. These bumps alert visually impaired pedestrians and signal them that they’re about to leave the sidewalk and enter a road. Plus, contrasting colors (often yellow or white) on ramp edges improve visibility during nighttime or in poor lighting.

What is Curb Ramp ADA?

A curb ramp that’s designed and installed exactly according to the Americans with Disabilities Act (ADA) mandated standards and regulations is called a curb ramp ADA. The ADA lawsuit makes sure that public spaces are accessible for people with disabilities. And curb ramps play a huge role in providing them accessibility and make movements easier between high surfaces and roads.

Key Features of ADA-Compliant Curb Ramps:

- The slope of the ramp should not exceed 1:12 (8.33%). Means you should do 1 inch of rise per 12 inches of ramp length.

- Facilities should ensure that the ramp is a minimum of 36 inches wide (excluding flared sides).

- You should ensure that curb ramps have truncated domes (textured yellow panels) for transition alert and increased visibility.

- Before installing curb ramps, you should ensure that you choose ramps with a nonslip surface. So during rainy or snowy days, these ramps don’t cause slipping.

- If the ramp is not protected by handrails, you should ensure that it sides must be flared (max slope 1:10).

- When you install curb ramps, you must ensure that the ramps are properly positioned to avoid drainage grates and obstructions.

Where Curb Ramps are Required?

Well, they are required anywhere a transition is needed. Such as between a sidewalk and a street or a driveway and a parking lot. Here are the main spots where curb ramps are a must and non-negotiable:

- At street crossings and intersections: So pedestrians, wheelchair users, strollers, and even kids can safely get on and off sidewalks.

- At accessible parking areas: Users can easily move from parking spots to walkways without jumping.

- In front of public buildings: At schools, hospitals, libraries, government offices, and even rehab centers, people with disabilities are always there. So here, ADA-compliant curb ramps are a must.

- At entrances of shopping malls and commercial areas: In such sites, people from different age groups and with different disabilities come. To ensure smooth entry for all types of customers, curb ramps are required at parking lots and sidewalks.

- In residential areas and driveways: Many homeowners install them in their private parking lots. Plus, facilities place them on sidewalks for people’s ease.

- Transit stops: Like bus stops or train stations, where people step off the vehicle and need a straight and ramped path.

Common Materials Used

Here are common materials that most curb ramp manufacturers use:

- Rubber: Rubber curb ramps are highly flexible, strong, and UV-wear-weather-and-corrosion-resistant. They are ideal for use outdoors for the long term and can easily bear the heavy load of vehicles.

- Plastic: Plastic curb ramps, on the other hand, are more lightweight than rubber ones, cost-effective, and tolerant. They have high strength, can easily resist heat, corrosion, and temperature, and maintain their performance longer.

- Composite of Rubber-Plastic: They are made with a mix of rubber and plastic material, so they have the advantages of both, are a more cost-effective solution, durable, flexible, strong, and can easily resist high loads, heat, and temperatures.

- Concrete: They are durable and last longer, require less maintenance, are slip-resistant, and can be customized (during installation). But they are more expensive to install, crack over time (due to load and impact), and are difficult to modify and relocate.

Parallel Curb Ramp VS Perpendicular Curb Ramp Vs Blended Transition Curb Ramp – What’s the Difference?

A parallel curb ramp is generally built in the same direction as the sidewalk (pedestrians’ walk direction). That way, people first move down the ramp and then turn to enter the street. Plus, these ramps don’t directly land pedestrians on roads. Instead, it lands in the same direction as the sidewalk. Ideal to install on narrow sidewalks or where space is limited.

A perpendicular curb ramp, on the other hand, is directly installed straight toward the street (in a perpendicular direction to the pedestrian path). So users directly move down the ramp into the crossing. Generally, they are placed at intersections, near traffic lights or crosswalks where there’s enough sidewalk depth.

A blended transition curb ramp is built differently. They don’t have a sharp change from sidewalk to street. Instead, within the sidewalk, the whole ramp area gradually lowers. This ramp lets pedestrians either land and cross the street or continue walking to the opposite side of the ramp. Often installed on narrow sidewalks.

Curb Ramp Driveway: Are They Worth It?

Absolutely, and there’s no reason to say no to this. Let’s say you have a car and your driveway has a sharp dip from the street. Every time you back out, your bumper hits the curb. We know it’ll be very annoying for you. But know that this occurrence over time is damaging your car.

But after you install a curb ramp on the driveway, whenever you back out, the curb ramp’s slope lets you back out smoothly. Without any hits or obstruction. That’s the difference a curb ramp makes.

Different Types of Curb Ramp Types (Based on Installation)

-

Permanent Curb Ramp

These ramps are designed and meant to be installed directly into the ground. Often made of concrete or heavy-duty rubber material. They are more durable, long-lasting, weather-resistant, heat-resistant, corrosion-resistant, and can easily bear loads. And that’s why it’s suitable for use in high-speed and high-traffic areas.

-

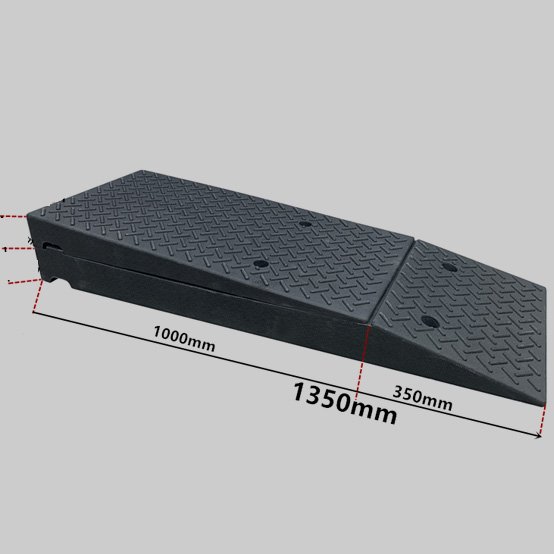

Modular Curb Ramp

They are available-to-customize solutions that come in sections. That means, you can assemble them (as much as you want) and create a ramp of your desired length, shape and size. Often made with rubber or steel material, and lasts longer. They’re lightweight, easy to install, remove, and transport. Often used in commercial or industrial settings.

-

Foldable Curb Ramp

As the name explains, these ramps can be foldable. Means, you can take them along with you everywhere. And when you need to park your car, or move your stroller or wheelchair from road surface to sidewalk (or vice versa), just place your ramp, pass over it, and fold it again.

Apart from that, if you’re a construction or event organizing company, you can also use a foldable curb ramp to provide accessibility of movement to everyone. That way, you can use the same curb ramps for multiple purposes, at different sites (saving you cost).

How to Choose the Best Curb Ramps for Cars?

- Firstly, check your curb height because not all ramps fit every curb. To measure the height, park your car near the curb, place a straight object from the road surface to over the curb. Then grab a scale/ ruler and measure the height. If you don’t want to check yourself, then here’s the tip: 2–4 inches (good for residential driveways), 4-6 (standard city curbs), 6+ inches (commercial/ industrial areas).

- The next step is to consider a ramp that can bear your vehicle’s weight capacity. Generally, most residential curb ramps weigh around 3,000–6,000 lbs and can easily handle standard cars and small SUVs. But if you drive a heavier vehicle (like a pickup truck, delivery van, or commercial ride), choose a ramp that supports at least 10,000+ lbs.

- Apart from weight, ensure the ramp you choose must match your car’s tire width (at least 12-18 inches).

- Next up, ensure to choose ramps that are non-slipping and can easily resist heat, corrosion, impact, and wear, like JACKWIN’s car curb ramps. Plus, our ramps are anti-slippery and come with built-in drainage holes. So water doesn’t collect underneath.

- Lastly, consider the installation method. If you’re renting or might shift homes, we suggest you go for portable/ foldable ramps. If you want permanent use, go for ramps that come with bolts for permanent fixing.

Advantages of Using Curb Ramps

Protects Your Vehicle: Without ramps, when you back out of your vehicle or have to move your car from the road surface to a higher parking lot, your car often gets hit or obstructed. But with curb stamps, your vehicle smoothly moves up or down, without damaging your vehicle (saving you repair costs).

Improves Accessibility: For people with disabilities, curb ramps provide a huge benefit. The ramps’ slope makes it easier for wheelchair users, strollers, and bikes to smoothly transition from sidewalks to roads. That’s why they’re also an ADA requirement in many public places.

Safety for All Pedestrians: Suppose a lady is dragging a shopping trolley, now imagine that when she walks down a steep curb, it can cause her to trip or fall. That’s where curb ramps shine. As they are designed with a non-slip, smooth slope that lets pedestrians move easily.

Improved Traffic Flow: When cars, bikes, strollers, and wheelchairs can all move up or down a curb smoothly, it naturally leads to better traffic flow. You know how? Because no drivers will need to slow down, as with the help of ramp, they can easily transition from sidewalk to crosswalks. This is especially helpful in busy driveways, schools, or commercial buildings.

How Much Does It Cost to Purchase and Install Curb Ramps?

Well, on average, plastic or rubber ramps (designed for light vehicles) usually start from $10 to $30 per piece. On the other hand, heavy-duty thick rubber or plastic ramps (designed for trucks or commercial vehicles) cost you around $20 to $50. On the other hand, concrete ramps may cost you around $200-$300 per linear foot.

But if you order from a trusted curb ramps supplier, like us, we can provide you with high-quality, non-slip, heat, corrosion, and wear-resistant ramps (plastic, rubber, composite material) at competitive wholesale prices.

Now, if we talk about installation cost, then the cost may range up to $500 to $1,500+, depending on the number of ramps that need to be installed, sizes, and material.

How Can You Do Curb Ramp Installation?

- First, clean the dust, dirt, and debris from the place where you intend to install the ramp. Once done, mark the ramp placement area using chalk for your ease.

- Next, check if the curb is too high. If so, then you need to cut it using a concrete saw for a smooth transition.

- Then, dry-fit the ramp panels. But make sure that there’s no gap between panels.

- After that, secure the ramp in its place. Now, you can do this either using adhesive (for light traffic) or anchor bolts/ concrete screws (for heavy traffic).

- Finally, walk or roll a wheelchair over the ramp and inspect if the ramp is properly fitted and stable.

Important: If you’re confused or not sure of slope calculations or anchoring, we suggest you hire a professional for ramp installation!

Wrapping It Up:

At this step, we hope that you now understand that curb ramps are not just important for the safety of people with disabilities, but also for the safety of other citizens. So if you’re a construction company or own a commercial or residential building and are looking for curb ramps at a wholesale rate, then JACKWIN is the best choice. We have been supplying OSHA and ADA-compliant curb ramps for 18+ years, in high-quality and durable materials. So contact us today and get a quick quote.

-80x69.png)