Supply & Wholesale Wheel Stoppers

JACKWIN is specialized in designing, producing, and wholesale all types of wheel stoppers. They are available both for indoor and outdoor use with long-lasting durability in parking lots(garage), driving schools, city streets,s or other areas that need park vehicles. They can prevent vehicles from sliding while parking, improve parking safety, and stop accidents.

Wheel Stopper Basics

Wheel Stopper is also known as curb stops or parking blocks, wheelstops, parking chocks, parking curbs, or parking bumpers, no matter which name it is, their function is the same, it is a curb installed on the parking space to block the wheels to prevent the car from rolling back, and it is also a parking locator to keep the car parked in the designated parking spot area.

Safety Tips: wheel stoppers can easily trip pedestrians, especially in dimly lit underground parking lots. Please kindly take care when you are in parking lots.

Best-selling Wheel Stoppers

JACKWIN provides full range of wheel stoppers varies in rubber and rubber/plastic composited material for your choice, please browse the follow wheel stoppers, we ensure there’s one for you.

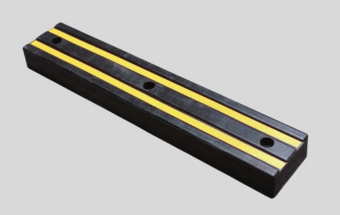

Size 500x150x100mm, rubber material, weight 3.7kg, yellow reflective band

Size 545x150x100mm, yellow reflective strips, rubber material, heavy-duty for truck

Truck Wheel Stoppers

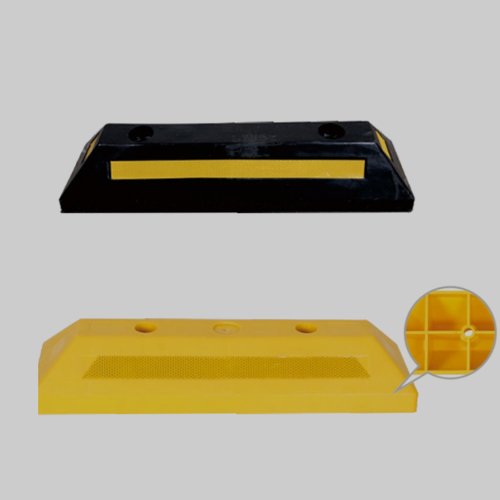

Size 550x150x100mm, two models for your option, yellow cover for screw hole

Wheel Stoppers for Cars

High-impact nylon and rubber material for choice, size 560x150x100mm

Size 570x120x80mm, 3kg weight, yellow and white reflective strips, 3 holes for screw mount

Car Park Wheel Stoppers

Size 600x120x100mm, 1.2kg weight, yellow glass beads reflective band

parking bumpers, size 750x150x110mm, 5.5kg weight, yellow glass bead reflector

parking curbs, size 900x150x100mm, weight 6.5kg, two optional models

size 1000x150x110mm, 7.2kg weight, yellow reflective band, 3 screw holes

Rubber Wheel Stoppers

heavy-duty parking chocks, 65 inches in length, high impact, designed for private garages

Rubber Wheel Stoppers

length 1830mm/72″ curb stops, 4 screw holes for installation, 3 optional models

Rubber Wheel Stoppers

size 78.75″Lx6″Wx5″H, parking blocks, free of UV light, oil and moisture

Made of plastic, high impact and weather conditions, resist 30 tons weight capacity

Wheel Stoppers By Properties

JACKWIN wheel stoppers have many high-quality and reliable features as follows:

high visible under low-light conditions, safety warning

best-in-class materials, ensure long-term performance and less maintenance

simple construction and can be installed easily by one person with anchors and bolts

great adaptability and functionality

stable and no fading under moisture, heat, and ultraviolet light

our rubber with fireproof material ingredients, good flame retardancy, and no rust

good anti-skid effect for wheels

softness helps to reduce the impact of the vehicle on the tire when parking

Your One-stop Supplier of Wheel Stopper

JACKWIN offers all types of wheel stoppers at low competitive wholesale prices. Our wheel stoppers include rubber, plastic(nylon), and rubber/plastic composition wheel stoppers, varying sizes from 500mm to 2000mm.

Materials Of Wheel Stopper

- 100% new rubber – Made of high-strength natural rubber, it has good compression resistance and a certain degree of softness. The yellow and black colors make it eye-catching and obvious, and it has the characteristics of deceleration, anti-skid, and wear resistance.

- Composition material of rubber and plastic, very competitive pricing, customizable in different colors. The slope has a certain degree of softness, which reduces the impact when parking. It can reflect dazzling light at night, making it clear to the driver at a glance.

- Recycled rubber – cost-effective option, high visibility at night, will not chip, crack, or fade. Good compression resistance.

- Plastic(nylon material), it’s flexible and impact-weather resistant, and with a reflector.

Wheel Stopper Package

All wheel stoppers of JACKWIN are packed in standardized pallets, with protective film and package belts to prevent rain and dust, and also have a tightening function, which is very suitable for forklift stacking operations in large warehouses.

Wheel Stopper’s Functions

- Avoid vehicle collision damage – Installing rubber wheel stoppers in parking spaces can avoid damage to buildings and cars caused by improper reversing. Even if the vehicle accidentally collides, the damage to buildings and cars can be minimized.

- Regulate parking order – Rubber wheel stopper is beautiful and can effectively regulate parking order, making parking spaces easy to identify and vehicles neatly arranged. It is suitable for various types of parking lots underground garages, etc.

- Assist vehicle positioning parking – It is convenient for drivers to safely and quickly reverse the vehicle into a fixed area.

- Play a warning role – The surface of the rubber wheel stopper is affixed with a wear-resistant, high-reflective yellow molded band, eye-catching and obvious, in line with international standards, and can play a warning role and attract the attention of drivers.

Resources

To learn more about JACKWIN products, please follow our knowledge center.

Rubber VS Rubber/plastic Composited Material

The advantages of the rubber wheel stoppers are better surface gloss, softness, good weather resistance, high density (heavyweight) and stronger impact resistance, but low production efficiency and high price.

The advantages of rubber/plastic composited material are high production efficiency, low price, good pressure resistance, and low density (lightweight). Because of its low price, it has been very popular in the market in recent years and is deeply loved by customers.

Wheel Stopper Applications

The application of wheel stopper is very simple, but the scenarios are different. Below we briefly list the usage scenarios.

our sturdy plastic or rubber wheel stoppers are used for outdoor parking lots and are weather-resistance, and water-proof.

used in parking spaces of various commercial supermarkets and plaza parking lots to facilitate customers to park.

Our Production Process

The production of wheel stoppers is relatively complicated, mainly including rubber mixing, slicing, weighing, vulcanization, and molding. Below we briefly introduce the production steps.

#1 Rubber material mixing, various raw materials are crushed and processed, then refined on an open mixing mill and processed into rolls for use. This production step is very dangerous and tests the workers’ carefulness at all times. They must be very careful not to get their hands caught in the machine.

#2 Cut them into blanks of a certain size by a cutting machine, and then the blanks are pressed into a preliminary shape using a mold under high pressure to ensure the close arrangement of rubber molecules to improve the strength and stability of the product.

#3 Vulcanization is a key step in rubber processing and is usually carried out in a special vulcanizer. The temperature and time need to be strictly controlled.

#4 Affix a wear-resistant, bright yellow molding band to increase the warning effect. At last, quality inspection is to ensure the ready products fulfill order requirements.

More About Our Wheel Stoppers & Company

JACKWIN’s wheel stoppers have undergone more than ten years of improvement and upgrading, from raw materials to design and details, and are more in line with the needs and satisfaction of end customers.. From the beginning to the end, we pay attention to the quality of our products, and we have a complete quality control process for every production detail from raw materials to finished products.

- Data Sheet

- After-Sales Service

- Gallery

| Material | Size | Weight |

| 100% recycled rubber | 900x150x100mm | 9.0 kgs |

| 100% recycled rubber | 1780x150x100mm | 16 kgs |

| 100% recycled rubber | 1650x150x100mm | 16 kgs |

| 100% recycled rubber | 1830x150x100mm | 15 kgs smooth surface |

| 100% recycled rubber | 1650x150x100mm | 12 kgs |

| 100% recycled rubber | 1830x150x100mm | 15 kgs embossed dots surface |

| Rubber and plastic | 550x150x100mm | 3.3 kgs |

| Rubber and plastic | 750x150x110mm | 5.8 kgs |

| Rubber and plastic | 900x150x100mm | 7.6 kgs |

| Rubber and plastic | 1650x150x100mm | 13.5 kgs |

| Rubber and plastic | 1830x150x100mm | 13.5 kgs |

| Rubber and plastic | 2000x150x100mm | 14 kgs |

| Rubber and plastic | 2000x150x100mm | 15 kgs |

All JACKWIN wheel stoppers have a 1-year warranty. If you meet any quality problems within one year of receiving the goods, please feel free to contact us and we will surely solve the problem for you first time.

Customers' Feedbacks

You can tell us your size of parking area and vehicles, use indoors or outdoors, and then we will suggest the correct one for you.

Normally in a woven bag then put on a pallet with wrap film, if you have special needs please notify us at the beginning then we will check for you.

Yes, all of JACKWIN wheel stoppers are installed high visible reflective band or reflector.

Related Product

Why Choose Jackwin?

We have a range of wheel stoppers with the highest quality to ramp up your experience.

- Fast and professional suggestion.

- Reliable material and product.

- Affordable prices here.

- Flexible payment methods.

How to Install Wheel Stopper?

(Wheel Stopper Installation Instruction)

The installation of wheel stoppers is very simple, the instructions are as follows:

1. Determine the installation location and do the positioning first. Place the wheel stopper at the location where it needs to be installed on the parking space, and use a marker to mark the location of the installation screw hole.

2. Use an electric or pneumatic impact drill to open it on the ground. It should be noted that the size of the hole must be the same as the diameter of the expansion screw screw, and the depth must be greater than or equal to the length of the screw.

3. Place the wheel stopper in the positioning position, the hole must be aligned with the hole, and then drive the expansion screw in to fix it.

4. Clean the construction site, clean the cement sand and gravel particles, and make the parking space clean and dust-free.

-80x69.png)